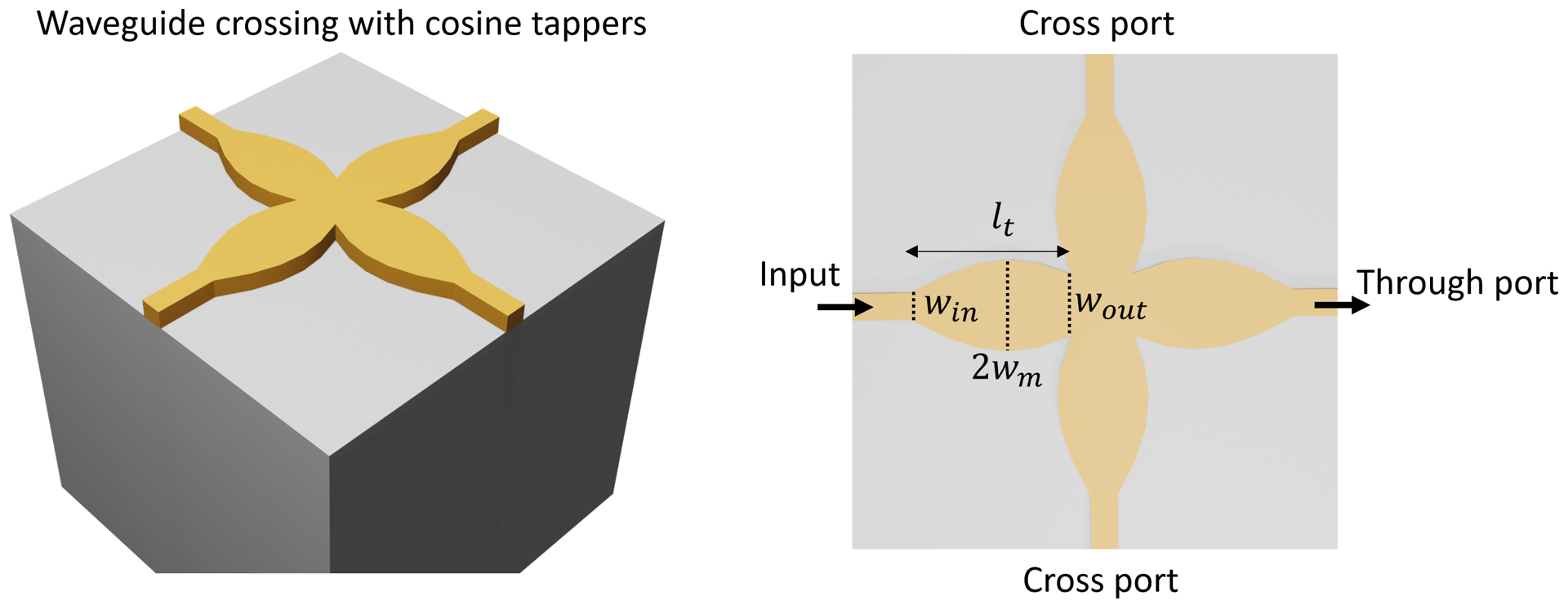

Waveguide crossing based on cosine tapers#

To achieve a high integration density on a photonic chip, efficient routing of light with low loss using compact junctions is necessary. Therefore, waveguide crossings are crucial building blocks in high performance integrated circuits.

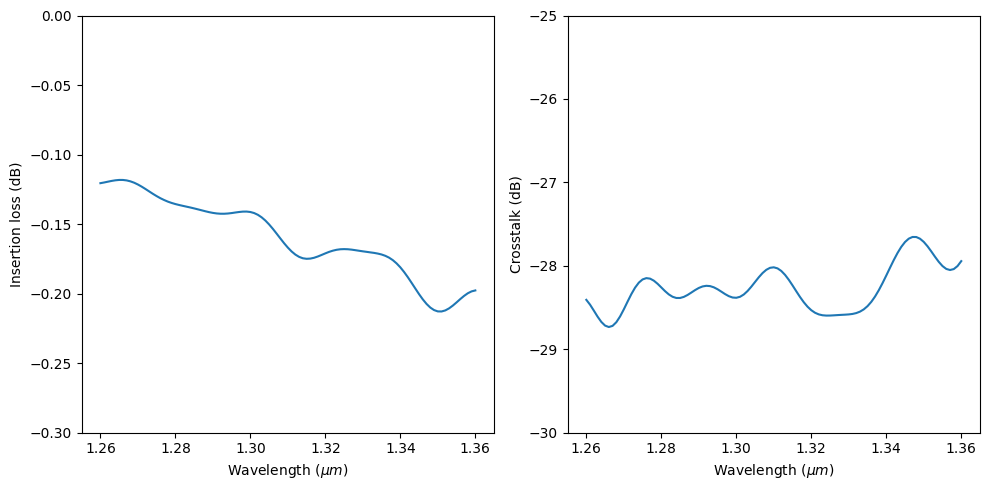

This example model demonstrates the simulation of a waveguide crossing based on cosine tapers. The convex cosine taper focuses the guided mode at the center of the crossing junction. This ensures the light is efficiently transmitted into the through port instead of scattered into the cross ports. The device achieves an insertion loss of ~0.2 dB and crosstalk ~-30 dB in the O-band (1260 nm -1360 nm). The design is adapted from Sujith Chandran, et al. “Beam shaping for ultra-compact waveguide crossings on monolithic silicon photonics platform,” Opt. Lett. 45, 6230-6233 (2020).

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials. For more simulation examples, please visit our examples page. FDTD simulations can diverge due to various reasons. If you run into any simulation divergence issues, please follow the steps outlined in our troubleshooting guide to resolve it.

[1]:

import matplotlib.pyplot as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

from scipy.optimize import fsolve

Simulation Setup#

Define geometric parameters and materials. In this device, the Si waveguide has a thickness of 161 nm and a width of 350 nm.

[2]:

h = 0.161 # waveguide thickness

w_in = 0.35 # input taper width

w_out = 1.1 # output taper width

w_m = 0.75 # amplitude of the cos function

l_t = 5.3 # taper length

inf_eff = 1000 # effective infinity used to make sure the waveguides extend into the pml

[3]:

si = td.Medium(permittivity=3.67**2)

sio2 = td.Medium(permittivity=1.45**2)

The taper width is described by a cosine function \(w(x)=w_m cos(ax+b)\). To determine the parameters \(a\) and \(b\), we solve a system of equations to ensure \(w(x)=w_{in}/2\) at the beginning of the taper and \(w(x)=w_{out}/2\) at the end of the taper. This can be easily done using fsolve from Scipy.

After we obtain \(w(x)\), vertices can be generated and the taper can be made using PolySlab. Once the first taper is made, the rest three tapers can be made by manipulating the vertices with the symmetry relation.

[4]:

# numerically solve for the cos function that describes the taper shape

def equations(x0):

a, b = x0

return (

w_m * np.cos(a * (-w_out / 2) + b) - w_out / 2,

w_m * np.cos(a * (-w_out / 2 - l_t) + b) - w_in / 2,

)

a, b = fsolve(equations, (0.5, 2))

x = np.linspace(-w_out / 2 - l_t, -w_out / 2, 30)

w = w_m * np.cos(a * x + b)

# using the calculated taper shape to construct the taper as a PolySlab

vertices = np.zeros((2 * len(x), 2))

vertices[:, 0] = np.concatenate((x, np.flipud(x)))

vertices[:, 1] = np.concatenate((w, -np.flipud(w)))

taper_1 = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h / 2, h / 2)),

medium=si,

)

# creating the other four tapers by manipulating the vertices of the first taper

vertices[:, 0] = -vertices[:, 0]

taper_2 = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h / 2, h / 2)),

medium=si,

)

vertices[:, [1, 0]] = vertices[:, [0, 1]]

taper_3 = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h / 2, h / 2)),

medium=si,

)

vertices[:, 1] = -vertices[:, 1]

taper_4 = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h / 2, h / 2)),

medium=si,

)

# creating the center crossing junction using a Box

corner = 0

center = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-w_out / 2 - corner, -w_out / 2 - corner, -h / 2),

rmax=(w_out / 2 + corner, w_out / 2 + corner, h / 2),

),

medium=si,

)

# creating the input port and through port

horizontal_wg = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -w_in / 2, -h / 2), rmax=(inf_eff, w_in / 2, h / 2)

),

medium=si,

)

# creating the cross ports

vertical_wg = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-w_in / 2, -inf_eff, -h / 2), rmax=(w_in / 2, inf_eff, h / 2)

),

medium=si,

)

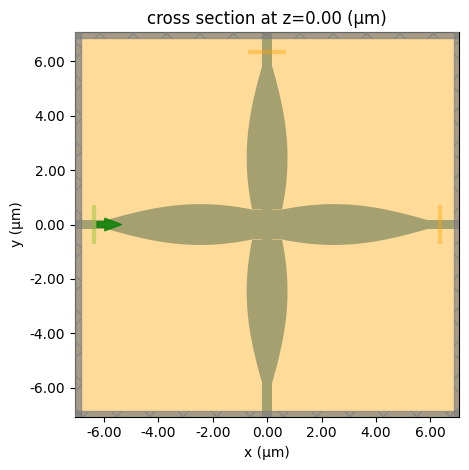

Set up simulation domain, source, and monitors. A mode source is used to excite the input waveguide. A field monitor at \(z=0\) plane is added to monitor the field propagation. Two flux monitors are added at the through port and cross port to monitor the transmission and crosstalk levels.

Before running the simulation, we can use the plot method to ensure the geometry, source, and monitors are set up correctly.

[5]:

lda0 = 1.31 # central wavelength

freq0 = td.C_0 / lda0 # operation frequency

ldas = np.linspace(1.26, 1.36, 101) # wavelength range of interest

freqs = td.C_0 / ldas # frequency range of interest

l_wg = 1 # input/output waveguide length

Lx = 2 * l_t + w_out + 2 * l_wg

Ly = 2 * l_t + w_out + 2 * l_wg

Lz = 1.5 * lda0

sim_size = (Lx, Ly, Lz)

# define a mode source for excitation using the lowest order mode

mode_source = td.ModeSource(

center=(-Lx / 2 + l_wg / 2, 0, 0),

size=(0, 4 * w_in, 4 * h),

source_time=td.GaussianPulse(freq0=freq0, fwidth=freq0 / 10),

direction="+",

mode_spec=td.ModeSpec(num_modes=1, target_neff=3.455, filter_pol="te"),

mode_index=0,

)

# add a field monitor at z=0 for field visualization

field_monitor = td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

# define a flux monitor to detect transmission to the through port

flux_monitor_through = td.FluxMonitor(

center=(Lx / 2 - l_wg / 2, 0, 0),

size=(0, 4 * w_in, 4 * h),

freqs=freqs,

name="flux_through",

)

# define a flux monitor to detect transmission to the cross port

flux_monitor_cross = td.FluxMonitor(

center=(0, Ly / 2 - l_wg / 2, 0),

size=(4 * w_in, 0, 4 * h),

freqs=freqs,

name="flux_cross",

)

sim = td.Simulation(

center=(0, 0, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=20, wavelength=lda0),

structures=[taper_1, taper_2, taper_3, taper_4, center, horizontal_wg, vertical_wg],

sources=[mode_source],

monitors=[field_monitor, flux_monitor_through, flux_monitor_cross],

run_time=1e-12,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

)

sim.plot(z=0)

plt.show()

To have a better visualization, we can also plot the simulation in 3D.

[6]:

sim.plot_3d()

Once the simulation set up is verified, submit job to the server. Before running the simulation, we can get a cost estimation using estimate_cost. This prevents us from accidentally running large jobs that we set up by mistake. The estimated cost is the maximum cost corresponding to running all the time steps.

[7]:

job = web.Job(simulation=sim, task_name="waveguide_crossing", verbose=True)

estimated_cost = web.estimate_cost(job.task_id)

12:32:41 CEST Created task 'waveguide_crossing' with task_id 'fdve-46a3cf65-cbe6-4aad-831d-3f6af99acdff' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-46a3cf65-cb e6-4aad-831d-3f6af99acdff'.

Task folder: 'default'.

12:32:43 CEST Maximum FlexCredit cost: 0.492. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

12:32:44 CEST Maximum FlexCredit cost: 0.492. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

The cost is reasonably so we can run the simulation.

[8]:

sim_data = job.run(path="data/simulation_data.hdf5")

12:32:45 CEST status = success

12:32:49 CEST loading simulation from data/simulation_data.hdf5

Result Visualization#

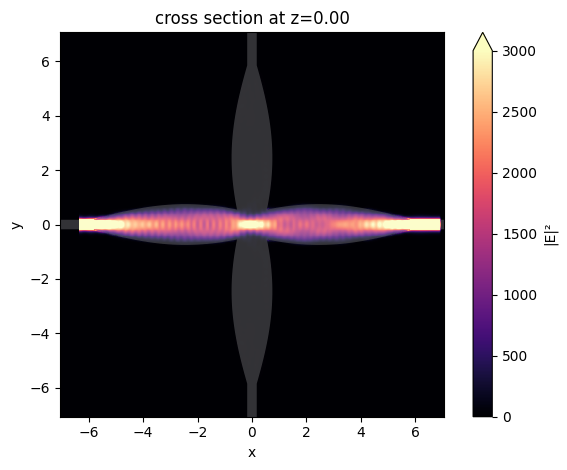

After the simulation is complete, first plot the field intensity distribution.

From the figure below, a good transmission to the through port is observed. In the crossing junction, a strong field focus is formed due to the focusing property of the cosine taper.

[9]:

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", f=freq0, vmin=0, vmax=3000

)

plt.show()

Finally, to quantify the designed waveguide crossing’s performance, plot insertion loss and crosstalk level.

[10]:

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 5))

T_through = sim_data["flux_through"].flux

T_cross = sim_data["flux_cross"].flux

ax1.plot(ldas, 10 * np.log10(T_through))

ax1.set_xlabel(r"Wavelength ($\mu m$)")

ax1.set_ylabel("Insertion loss (dB)")

ax1.set_ylim((-0.3, 0))

ax2.plot(ldas, 10 * np.log10(T_cross / T_through))

ax2.set_xlabel(r"Wavelength ($\mu m$)")

ax2.set_ylabel("Crosstalk (dB)")

ax2.set_ylim((-30, -25))

plt.show()

[ ]: