Fabrication-aware inverse design (FAID) of a wavelength division multiplexer#

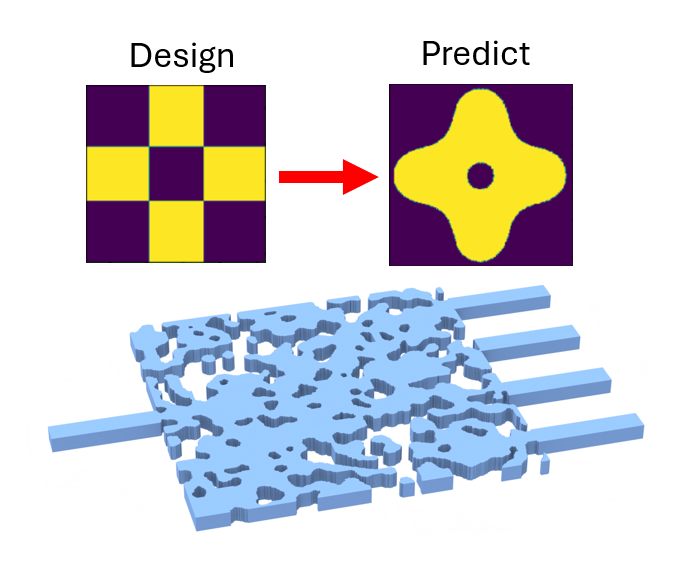

This notebook extends the Adjoint Optimization of a Wavelength Division Multiplexer by incorporating fabrication awareness into the design process. Specifically, we integrate a differentiable computer vision model from PreFab Photonics into the topology optimization loop to predict and optimize the manufacturability of photonic device designs. This approach, known as fabrication-aware inverse design (FAID), results in devices that are inherently more robust to fabrication variations.

Unlike optical proximity correction (OPC), which adjusts designs to compensate for lithography-induced distortions after the design phase, FAID directly optimizes for manufacturable designs by using fabrication predictions within the design loop. While OPC can enhance design fidelity, it may not ensure manufacturability for complex features. FAID focuses on creating features that are inherently realizable by the fabrication process, leading to designs that are more practical to manufacture.

For a deeper look at the FAID concept, refer to this paper by Lukas Chrostowski’s group at the University of British Columbia. Additional information on PreFab’s virtual nanofabrication models can be found in the PreFab documentation.

[1]:

import autograd as ag

import autograd.numpy as anp

import matplotlib.pylab as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

np.random.seed(2)

PreFab Setup#

First, we will need to install the latest PreFab Python package.

[ ]:

%pip install --upgrade prefab

PreFab models operate on a cloud platform. To make prediction requests, you must first create an account. Run the following cell or visit the PreFab website to create an account.

[2]:

import webbrowser

_ = webbrowser.open("https://www.prefabphotonics.com/signup")

To associate your account, a token is required. This action will prompt a browser window to open, allowing you to log in and authenticate your token.

[3]:

# !prefab setup

Lastly, to verify that PreFab is properly configured, we can make a test prediction request.

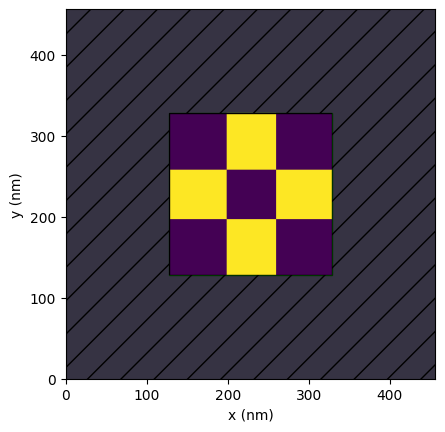

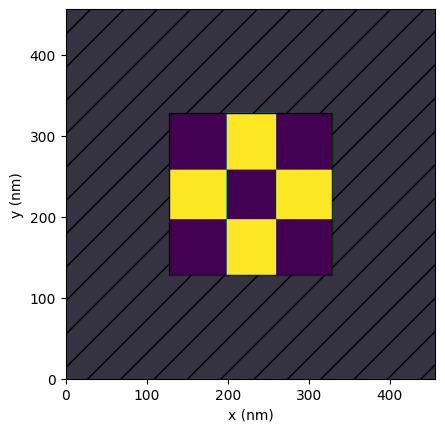

From the test prediction results below, we can see how the predicted structure undergoes corner rounding and loss of small features, as expected from the fabrication process.

[4]:

import prefab as pf

device = pf.shapes.target()

prediction = device.predict(model=pf.models["ANT_NanoSOI_ANF1_d10"], binarize=True)

device.plot()

prediction.plot()

[4]:

<Axes: xlabel='x (nm)', ylabel='y (nm)'>

Predicting Device Performance#

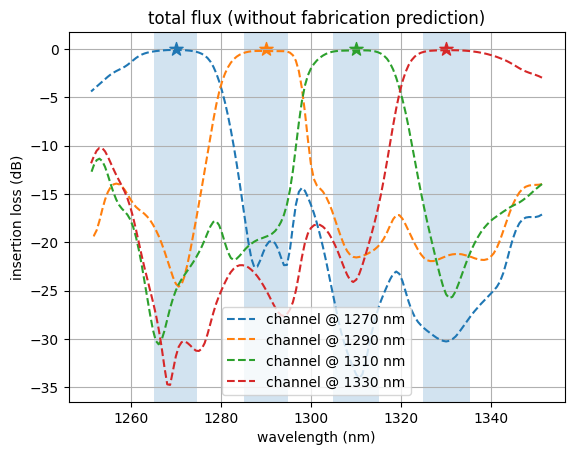

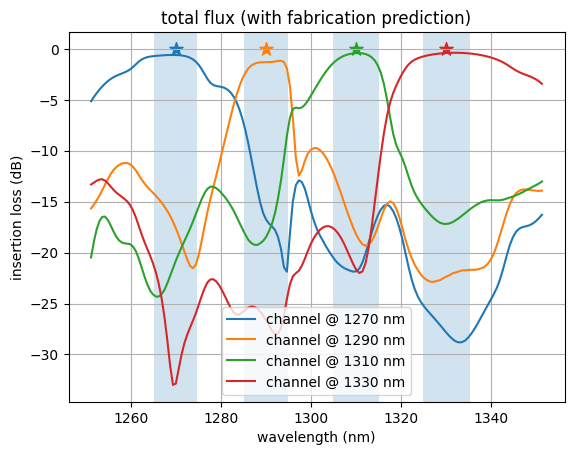

Using the prediction model, we can simulate the expected experimental performance of device designs such as the wavelength division multiplexer (WDM) in the Adjoint Optimization of a Wavelength Division Multiplexer. The WDM was optimized with a relatively large feature size and an erosion/dilation penalty to enhance robustness against fabrication variations. This optimization allows it to tolerate predicted fabrication variations quite well; however, some performance degradation is still observed. As illustrated in the figure below, the fabrication-predicted transmission spectra get distorted, insertion loss is increased, and further crosstalk is introduced. This performance degradation can be mitigated with FAID.

Simulation Setup#

Here we set up our basic simulation for the FAID optimization.

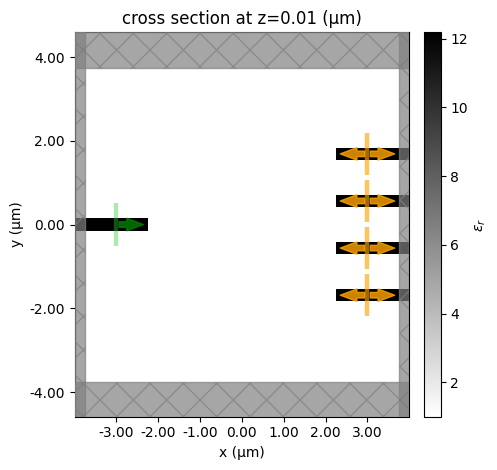

We have an input waveguide connected to a square design region, which has n=4 output waveguides.

The square design region is a custom medium with a pixelated permittivity grid that we wish to optimize such that input light of different wavelengths gets directed to different output ports.

As this is a SOI device, we typically define the design region and waveguides as Silicon sitting on a SiO2 substrate. For this demo, we make a 2D simulation, but it can be easily made 3D by changing the Lz parameter, adding dimension to the structures, and adding a substrate.

[6]:

# material information

n_si = 3.49

n_sio2 = 1.45 # not used in 2D

n_air = 1

# channel wavelengths

wvls_design = np.array([1.270, 1.290, 1.310, 1.330])

freqs_design = td.C_0 / wvls_design

num_freqs_design = len(freqs_design)

freq_max = np.max(freqs_design)

freq_min = np.min(freqs_design)

keys = [str(i) for i in range(num_freqs_design)]

df_design = abs(np.mean(np.diff(freqs_design)))

# forward source

freq0 = np.mean(freqs_design)

wvl0 = td.C_0 / freq0

fwidth = freq_max - freq_min

run_time = 120 / fwidth

# we average the metrics over the channels with some frequency width

channel_fwidth = df_design / 2.0

channel_bounds = [(f - channel_fwidth / 2, f + channel_fwidth / 2) for f in freqs_design]

num_freqs_channel = 5

channel_freqs = []

for fmin, fmax in channel_bounds:

sub_freqs = np.linspace(fmin, fmax, num_freqs_channel)

channel_freqs += sub_freqs.tolist()

# size of design region

lx = 4.5

ly = 4.5

ly_single = ly / num_freqs_design

lz = td.inf

# size of waveguides

wg_width = 0.3

wg_length = 1.5

wg_spacing = 0.8

# spacing between design region and PML in y

buffer = 1.5

# size of simulation

Lx = lx + wg_length * 2

Ly = ly + buffer * 2

Lz = 0.0

# fabrication constraints (feature size and projection strength)

radius = 0.100

beta0 = 2

# resolution information

min_steps_per_wvl = 18

dl_design_region = 0.015

Base Simulation#

First, we’ll define the simulation without any design region using the “base” components that don’t change over the optimization.

[7]:

# define the waveguide ports

wg_in = td.Structure(

geometry=td.Box(

center=(-Lx / 2, 0, 0),

size=(wg_length * 2, wg_width, lz),

),

medium=td.Medium(permittivity=n_si**2),

)

centers_y = np.linspace(-ly / 2.0 + ly_single / 2.0, +ly / 2.0 - ly_single / 2.0, num_freqs_design)

mode_size = (0, 0.9 * ly_single, td.inf)

wgs_out = []

for center_y in centers_y:

wg_out = td.Structure(

geometry=td.Box(

center=(+Lx / 2, center_y, 0),

size=(wg_length * 2, wg_width, lz),

),

medium=td.Medium(permittivity=n_si**2),

)

wgs_out.append(wg_out)

# measure the mode amplitudes at each of the output ports

mnts_mode = []

for key, center_y in zip(keys, centers_y):

mnt_mode = td.ModeMonitor(

center=(Lx / 2 - wg_length / 2, center_y, 0),

size=mode_size,

freqs=channel_freqs,

mode_spec=td.ModeSpec(),

name=f"mode_{key}",

)

mnts_mode.append(mnt_mode)

# measures the flux at each of the output ports

mnts_flux = []

for key, center_y in zip(keys, centers_y):

mnt_flux = td.FluxMonitor(

center=(Lx / 2 - wg_length / 2, center_y, 0),

size=mode_size,

freqs=channel_freqs,

name=f"flux_{key}",

)

mnts_flux.append(mnt_flux)

# and a field monitor that measures fields on the z=0 plane at the design freqs

fld_mnt = td.FieldMonitor(

center=(0, 0, 0),

size=(td.inf, td.inf, 0),

freqs=freqs_design,

name="field",

)

# inject the fundamental mode into the input waveguide

mode_src = td.ModeSource(

center=(-Lx / 2 + wg_length / 2, 0, 0),

size=mode_size,

source_time=td.GaussianPulse(

freq0=freq0,

fwidth=fwidth,

),

direction="+",

mode_index=0,

)

sim_base = td.Simulation(

size=(Lx, Ly, Lz),

grid_spec=td.GridSpec.auto(

min_steps_per_wvl=min_steps_per_wvl,

wavelength=np.min(wvls_design),

),

structures=[wg_in] + wgs_out,

sources=[mode_src],

monitors=mnts_mode + mnts_flux + [fld_mnt],

boundary_spec=td.BoundarySpec.pml(x=True, y=True, z=True if Lz else False),

run_time=run_time,

)

[8]:

ax = sim_base.plot_eps(z=0.01)

ax.set_aspect("equal")

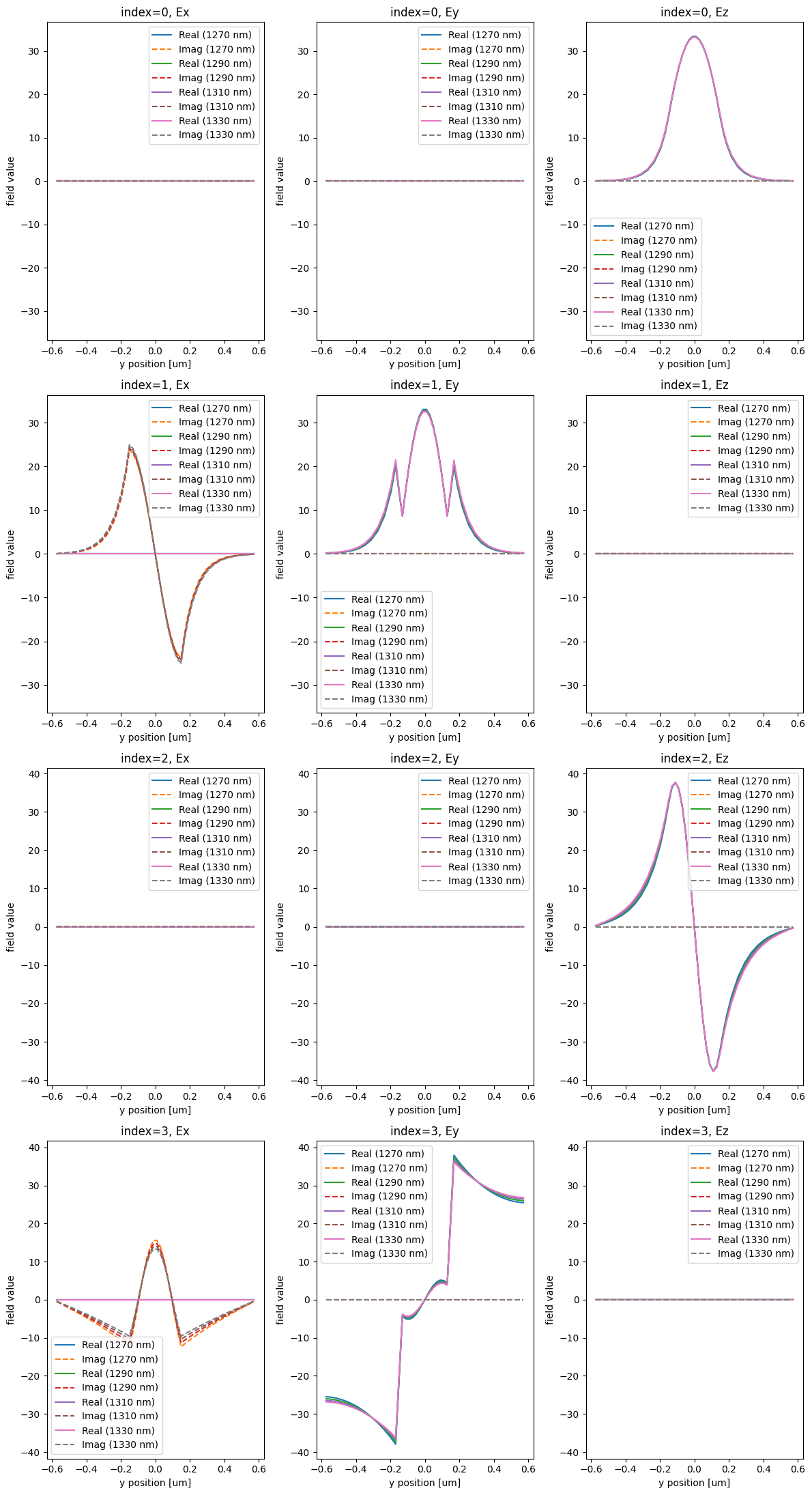

Solving for Modes#

Next, we want to ensure that we are injecting and measuring the right waveguide modes at each of the ports.

We’ll use tidy3d’s ModeSolver to analyze the modes of our input waveguide.

[9]:

from tidy3d.plugins.mode import ModeSolver

from tidy3d.plugins.mode.web import run as run_mode_solver

# we'll ask for 4 modes just to inspect

num_modes = 4

# let's define how large the mode planes are and how far they are from the PML relative to the design region

mode_size = (0, ly_single, td.inf)

# make a plane corresponding to where we wish to measure the input mode

plane_in = td.Box(

center=(-Lx / 2 + wg_length / 2.0, 0, 0),

size=mode_size,

)

mode_solver = ModeSolver(

simulation=sim_base,

plane=plane_in,

freqs=freqs_design,

mode_spec=td.ModeSpec(num_modes=num_modes),

)

Next we run the mode solver on the servers.

[10]:

mode_data = run_mode_solver(

mode_solver, reduce_simulation=True, results_file="data/mode_solver.hdf5"

)

17:41:45 CEST Mode solver created with task_id='fdve-9ab03835-92f4-42e6-8a5f-d21a30e41c42', solver_id='mo-cbcdb702-9026-4ef1-b671-a476e6fd46df'.

/home/marco/projects/tidy3d-notebooks/.venv/lib/python3.12/site-packages/rich/li

ve.py:231: UserWarning: install "ipywidgets" for Jupyter support

warnings.warn('install "ipywidgets" for Jupyter support')

17:41:54 CEST Mode solver status: queued

---------------------------------------------------------------------------

KeyboardInterrupt Traceback (most recent call last)

Cell In[10], line 1

----> 1 mode_data = run_mode_solver(

2 mode_solver, reduce_simulation=True, results_file="data/mode_solver.hdf5"

3 )

File ~/projects/tidy3d-notebooks/.venv/lib/python3.12/site-packages/tidy3d/web/api/mode.py:129, in run(mode_solver, task_name, mode_solver_name, folder_name, results_file, verbose, progress_callback_upload, progress_callback_download, reduce_simulation, pay_type)

127 console.log(f"Mode solver status: {status}")

128 prev_status = status

--> 129 time.sleep(0.5)

130 status = task.get_info().status

132 if status == "error":

KeyboardInterrupt:

And visualize the results.

[11]:

fig, axs = plt.subplots(num_modes, 3, figsize=(12, 22), tight_layout=True)

for mode_index in range(num_modes):

vmax = 1.1 * max(

abs(mode_data.field_components[n].sel(mode_index=mode_index)).max()

for n in ("Ex", "Ey", "Ez")

)

for field_name, ax in zip(("Ex", "Ey", "Ez"), axs[mode_index]):

for freq in freqs_design:

key = f"{td.C_0 / freq * 1000:.0f} nm"

field = mode_data.field_components[field_name].sel(mode_index=mode_index, f=freq)

field.real.plot(label=f"Real ({key})", ax=ax)

field.imag.plot(ls="--", label=f"Imag ({key})", ax=ax)

ax.set_title(f"index={mode_index}, {field_name}")

ax.set_ylim(-vmax, vmax)

ax.legend()

print("Effective index of computed modes: ", np.array(mode_data.n_eff))

Effective index of computed modes: [[3.1513898 2.840793 2.006425 1.0989405]

[3.1436877 2.8191965 1.970435 1.0913303]

[3.1359682 2.797195 1.934321 1.0847051]

[3.1282325 2.7747855 1.8980899 1.0788841]]

We identify mode_index=0 as the first order mode that is out of plane of the device. Let’s choose to optimize our device with respect to this as the mode of interest for both the input and output.

We’ll update or Base Simulation with the new mode index and mode specification, in case these are different from the original ones.

[11]:

mode_index = 0

mode_spec = td.ModeSpec(num_modes=mode_index + 1)

sim_base = sim_base.updated_copy(mode_index=mode_index, path="sources/0")

sim_base = sim_base.updated_copy(mode_spec=mode_spec, path="sources/0")

for i in range(num_freqs_design):

sim_base = sim_base.updated_copy(mode_spec=mode_spec, path=f"monitors/{i}")

Define Design Region#

Next, we define the design region as a pixelated grid of permittivity values that get generated from our optimization parameters.

We first define the overall geometry as a td.Box and also the number of pixels in x and y based on our design region resolution.

[12]:

nx = int(lx / dl_design_region)

ny = int(ly / dl_design_region)

design_region_geo = td.Box(size=(lx, ly, lz), center=(0, 0, 0))

PreFab models function on a grid with a 1 nm resolution. To use the prediction function effectively, we adjust our simulation design region to match this resolution. We also add a buffer layer to the design region to account for the interface between it and the waveguides. Afterward, we will convert it back to the original size and resolution.

While this process introduces discretization error, it can be minimized by using a higher simulation resolution—which is recommended for production designs.

Note: We’ll use a model for the electron-beam lithography process from Applied Nanotools Inc. (ANT) for the prediction.

[13]:

FAB_MODEL = pf.models["ANT_NanoSOI_ANF1_d10"]

prediction_buffer = 0.16

n_prediction_buffer = int(prediction_buffer / dl_design_region)

def resize_array(array: np.ndarray, scale: float) -> np.ndarray:

H, W = array.shape

"""Array resizing using bilinear interpolation."""

new_H = int(H * scale)

new_W = int(W * scale)

x = anp.linspace(0, W - 1, new_W)

y = anp.linspace(0, H - 1, new_H)

x_grid, y_grid = anp.meshgrid(x, y)

x0 = anp.floor(x_grid).astype(int)

x1 = x0 + 1

y0 = anp.floor(y_grid).astype(int)

y1 = y0 + 1

x0 = anp.clip(x0, 0, W - 1)

x1 = anp.clip(x1, 0, W - 1)

y0 = anp.clip(y0, 0, H - 1)

y1 = anp.clip(y1, 0, H - 1)

Ia = array[y0, x0]

Ib = array[y1, x0]

Ic = array[y0, x1]

Id = array[y1, x1]

wa = (x1 - x_grid) * (y1 - y_grid)

wb = (x1 - x_grid) * (y_grid - y0)

wc = (x_grid - x0) * (y1 - y_grid)

wd = (x_grid - x0) * (y_grid - y0)

resized_image = wa * Ia + wb * Ib + wc * Ic + wd * Id

return resized_image

def add_prediction_buffer(params):

"""Add a buffer layer to the design region. This is useful for predicting the interface between the design region and the waveguides."""

params = anp.pad(params, pad_width=n_prediction_buffer, mode="constant", constant_values=0)

wg_mask = anp.zeros_like(params)

center_y_mask = wg_mask.shape[1] // 2

# add input waveguide to mask

wg_half_width = int((wg_width / 2) / dl_design_region)

wg_mask[

0:n_prediction_buffer,

center_y_mask - wg_half_width : center_y_mask + wg_half_width,

] = 1

# add output waveguides to mask

for center_y in centers_y:

wg_center = int(center_y / dl_design_region)

wg_mask[

-n_prediction_buffer:,

center_y_mask + wg_center - wg_half_width : center_y_mask + wg_center + wg_half_width,

] = 1

return params * (1 - wg_mask) + wg_mask

def params_to_device_array(params: np.ndarray, scale: float, pad_width: int = 100) -> np.ndarray:

"""Convert params to a device array at 1 nm resolution."""

params = add_prediction_buffer(params)

device_array = resize_array(params, scale)

return device_array

def device_array_to_params(

device_array: np.ndarray, scale: float, pad_width: int = 100

) -> np.ndarray:

"""Convert device array to params at the original resolution."""

params = resize_array(device_array, 1 / scale)

params = params[

n_prediction_buffer:-n_prediction_buffer,

n_prediction_buffer:-n_prediction_buffer,

]

return params

Next we write a function to give us the pixelated array as a function of our parameters through our filtering and projection methods, which are used to make the resulting structures easier to fabricate. For more details, refer to our 4th lecture in the inverse design 101 lecture series, which focuses on fabrication constraints.

We also wrap this function in another one that generates the entire td.Structure corresponding to the design region, for convenience later.

For FAID: During each iteration, we predict the fabrication variation of the structure and incorporate the new geometry into the simulation. This approach allows us to optimize a “virtual” structure, which accounts for fabrication imperfections, rather than an idealized version. We introduce a

use_predictflag here.

[14]:

from tidy3d.plugins.autograd import make_filter_and_project, rescale

filter_project = make_filter_and_project(radius, dl_design_region)

def get_density(params: np.ndarray, beta: float) -> np.ndarray:

"""Get the density of material (0, 1) as a function of the parameters (0,1)"""

return filter_project(params, beta=beta)

def make_eps(params: np.ndarray, beta: float, use_predict: bool = False) -> np.ndarray:

"""Generates permittivity values for the design region, optionally using a PreFab prediction model to account for manufacturing variations."""

density = get_density(params, beta=beta)

# ********** START OF ADDED PREFAB CODE **********

if use_predict:

device_array = params_to_device_array(density, dl_design_region * 1000)

prediction_array = pf.predict.predict_array_with_grad(device_array, FAB_MODEL)

predicted_density = device_array_to_params(prediction_array, dl_design_region * 1000)

return rescale(predicted_density, 1, n_si**2)

# ********** END OF ADDED PREFAB CODE **********

else:

return rescale(density, 1, n_si**2)

def make_custom_medium(params: np.ndarray, beta: float, use_predict: bool = False) -> td.Structure:

"""Make td.Structure containing custom medium with the permittivity data as a function of parameters."""

eps = make_eps(params, beta, use_predict).reshape((nx, ny, 1))

xs = anp.linspace(-lx / 2, lx / 2, nx)

ys = anp.linspace(-ly / 2, ly / 2, ny)

zs = [0]

coords = dict(x=xs, y=ys, z=zs)

eps_arr = td.ScalarFieldDataArray(data=eps, coords=coords)

medium = td.CustomMedium(permittivity=eps_arr)

return td.Structure(geometry=design_region_geo, medium=medium)

Construct Simulation#

With all of these functions and variables defined, we can write a single function to return our “base” td.Simulation as a function of our design parameters. This function first constructs the design region, a mesh override structure to control the resolution in this region, and then creates a copy of the original td.Simulation with all of the basic parameters.

[15]:

def get_sim(params, beta, include_extra_mnts: bool = True, use_predict: bool = False):

design_region = make_custom_medium(params, beta=beta, use_predict=use_predict)

design_override = td.MeshOverrideStructure(

geometry=design_region.geometry,

dl=[dl_design_region, dl_design_region, dl_design_region],

)

grid_spec = sim_base.grid_spec.updated_copy(

override_structures=list(sim_base.grid_spec.override_structures) + [design_override]

)

update_dict = dict(

structures=list(sim_base.structures) + [design_region],

grid_spec=grid_spec,

)

# if include_extra_mnts is False, update sim to only include mode monitors, to save data.

if not include_extra_mnts:

update_dict["monitors"] = mnts_mode

return sim_base.updated_copy(**update_dict)

Let’s test out our function. We’ll make an initially random array of parameters between 0 and 1 and generate the Base Simulation to plot and inspect.

[17]:

params0 = np.random.random((nx, ny))

sim0 = get_sim(params0, beta=beta0, use_predict=False)

[18]:

ax = sim0.plot_eps(z=0.01)

ax.set_aspect("equal")

Defining Objective Function#

With our simulation fully defined as a function of our parameters, we are ready to define our objective function.

In this case, it is quite simple. We simply measure the transmitted power in our num_freqs = 4 output waveguide modes for each of the num_freqs = 4 design frequencies.

Our objective when looking at waveguide i will be to maximize power transmission at frequency i. To reduce cross-talk between waveguide i and frequency j != i, we will subtract the average of the power transmissions for all of the other ports.

Our overall metric will then be the average

[19]:

import xarray as xr

def average_over_channel(spectrum: xr.DataArray, fmin: float, fmax: float) -> xr.DataArray:

"""Get average of the spectrum within the frequency range between fmin and fmax."""

freqs = spectrum.f

freqs_in_channel = np.logical_and(freqs >= fmin, freqs <= fmax).values

num_freqs = np.sum(freqs_in_channel)

avg_power = spectrum.values @ freqs_in_channel / num_freqs

return avg_power

def get_power(sim_data: td.SimulationData, mnt_index: int, freq_index: int) -> float:

"""Get the average power at waveguide `mnt_index` and frequency channel `freq_index`."""

mnt_name = mnts_mode[mnt_index].name

mnt_data = sim_data[mnt_name]

fmin_channel, fmax_channel = channel_bounds[freq_index]

amp = mnt_data.amps.sel(direction="+", mode_index=0)

power_spectrum = anp.abs(amp) ** 2

return average_over_channel(power_spectrum, fmin=fmin_channel, fmax=fmax_channel)

def get_metric(sim_data: td.SimulationData, mnt_index: int, leak_weight: float = 1.0) -> float:

"""measure of how well this channel (`mnt_index`) performs. With an adjustable weight to reduce cross talk influence."""

power_all = [

get_power(sim_data=sim_data, mnt_index=mnt_index, freq_index=j)

for j in range(num_freqs_design)

]

power_transmitted = power_all[mnt_index]

# remove the extra term of power_self in power_all

power_leaked = sum(power_all) - power_transmitted

avg_power_leaked = power_leaked / (num_freqs_design - 1)

return power_transmitted - leak_weight * avg_power_leaked

Next we add a penalty to produce structures that are invariant under erosion and dilation, which is a useful approach to implementing minimum length scale features.

[20]:

from tidy3d.plugins.autograd import make_erosion_dilation_penalty

beta_penalty = 10

penalty = make_erosion_dilation_penalty(radius, dl_design_region, beta=beta_penalty)

Total Objective Function#

Then we write an objective function that constructs our simulation, runs it, measures our metric, and subtracts our penalty.

Note: due to the current limitations of the autograd support in tidy3d, when running broadband simulations, one must have only a single output ‘port’ in the forward simulation. Therefore, we split our problem into one simulation per output waveguide, and then run these in parallel using

web.run().

For FAID: We set

use_predict=Trueanduse_penalty=False.

[ ]:

# useful for debugging, if you want to turn off the metric, penalty, or prediction

use_penalty = False

use_metric = True

use_predict = True

def objective(params, beta: float, penalty_weight: float = 1.0, leak_weight: float = 0.0) -> float:

metric = 0.0

penalty_value = 0.0

if use_metric:

sim = get_sim(params, beta=beta, include_extra_mnts=False, use_predict=use_predict)

simulations = {f"WDM_invdes_{key}": sim for key in keys}

batch_data = web.run(simulations, verbose=False, path="data")

metric = 0.0

for mnt_index, (_, sim_data) in enumerate(batch_data.items()):

metric = metric + get_metric(

sim_data=sim_data, mnt_index=mnt_index, leak_weight=leak_weight

)

metric = metric / num_freqs_design

if use_penalty:

penalty_value = penalty(params)

return metric - penalty_weight * penalty_value

Differentiating the Objective#

Finally, we can simply use autograd (ag) to transform this objective function into a function that returns our objective function value and our gradient, which we will feed to the optimizer.

[22]:

grad_fn = ag.value_and_grad(objective)

Let’s try out our gradient function.

[ ]:

J, grad = grad_fn(params0, beta=1)

[24]:

print(J)

print(grad.shape)

print(np.linalg.norm(grad))

0.09930831775707324

(300, 300)

0.004744553423072362

Run Optimization#

Finally, we are ready to optimize our device. We will make use of the optax package to define an optimizer using the adam method, as we’ve done in the previous inverse design tutorials.

We record a history of objective function values, and parameters, for visualization later.

For FAID: The PreFab prediction will add close to a minute to the runtime of each iteration.

[25]:

import os

import pickle

import optax

# check if the optimization history file exists

history_file_path = "misc/optimization_history_FAID_4ch_R100_1filter_buffer.pkl"

if os.path.exists(history_file_path):

# load the saved optimization history

with open(history_file_path, "rb") as f:

data_history = pickle.load(f)

Js = data_history["Js"]

params_history = data_history["params_history"]

beta_history = data_history["beta_history"]

opt_state = data_history["opt_state"]

start_step = len(Js)

print(f"Loaded {start_step} steps from history file.")

params = params_history[-1]

else:

# initialize new optimization history

Js = []

params_history = [params0]

beta_history = []

start_step = 0

params = 0.5 * np.ones_like(params0)

opt_state = None

# hyperparameters

num_steps = 70

learning_rate = 0.1

beta_min = 1

beta_max = 50

# initialize the optimizer with the last known state

optimizer = optax.adam(learning_rate=learning_rate)

if opt_state is None:

opt_state = optimizer.init(params)

for i in range(start_step, num_steps):

perc_done = i / (num_steps - 1)

# in case we want to change parameters over the optimization procedure

one_third = 1.0 / 3.0

penalty_weight = 1.0

leak_weight = 0.0 if perc_done < one_third else 1.0

beta_i = beta_min * (1 - perc_done) + beta_max * perc_done

# make a plot of density to check on progress

density = get_density(params, beta_i)

plt.subplots(figsize=(2, 2))

plt.imshow(np.flipud(1 - density.T), cmap="gray", vmin=0, vmax=1)

plt.axis("off")

plt.show()

# compute gradient and current objective function value

value, gradient = grad_fn(

params, beta=beta_i, penalty_weight=penalty_weight, leak_weight=leak_weight

)

# outputs

print(f"step = {i + 1}")

print(f"\tJ = {value:.4e}")

print(f"\tbeta = {beta_i:.2f}")

print(f"\tgrad_norm = {np.linalg.norm(gradient):.4e}")

# compute and apply updates to the optimizer based on gradient (-1 sign to maximize obj_fn)

updates, opt_state = optimizer.update(-gradient, opt_state, params)

params[:] = optax.apply_updates(params, updates)

# keep params between 0 and 1

np.clip(params, 0.0, 1.0, out=params)

# save history

Js.append(value)

params_history.append(params.copy())

beta_history.append(beta_i)

data_to_save = {

"Js": Js,

"params_history": params_history,

"beta_history": beta_history,

"opt_state": opt_state,

}

with open(history_file_path, "wb") as f:

pickle.dump(data_to_save, f)

Loaded 70 steps from history file.

Visualize Results#

Let’s visualize the results of our optimization.

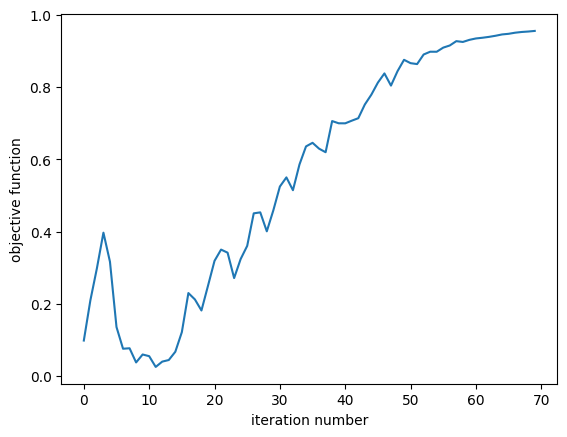

Objective Function vs Iteration#

First we inspect the objective function value as a function of optimization iteration number. We see that it steadily increases as expected.

[26]:

plt.plot(Js)

plt.xlabel("iteration number")

plt.ylabel("objective function")

plt.show()

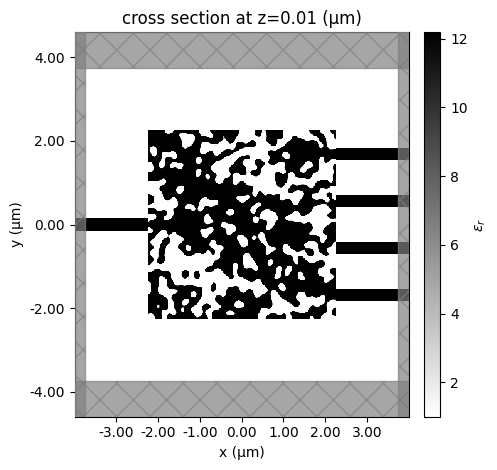

Final Simulation#

Let’s take a look at the final simulation, without the prediction model, which we grab from our history.

[27]:

# we'll sample the modes at a finer frequency resolution for this final evaluation, for smoother plots

iter_final = -1

num_freqs_measure = 151

freqs_measure = np.linspace(freq_min - df_design, freq_max + df_design, num_freqs_measure)

sim_final = get_sim(params_history[iter_final], beta=beta_history[iter_final], use_predict=False)

for i in range(num_freqs_design):

sim_final = sim_final.updated_copy(freqs=freqs_measure, path=f"monitors/{i}")

sim_final = sim_final.updated_copy(freqs=freqs_measure, path=f"monitors/{i + num_freqs_design}")

[28]:

ax = sim_final.plot_eps(z=0.01, monitor_alpha=0, source_alpha=0)

[29]:

penalty_value_final = penalty(params_history[-1])

print(penalty_value_final)

0.4385708213150775

[30]:

sim_data_final = web.run(sim_final, verbose=False, task_name="wdm_final")

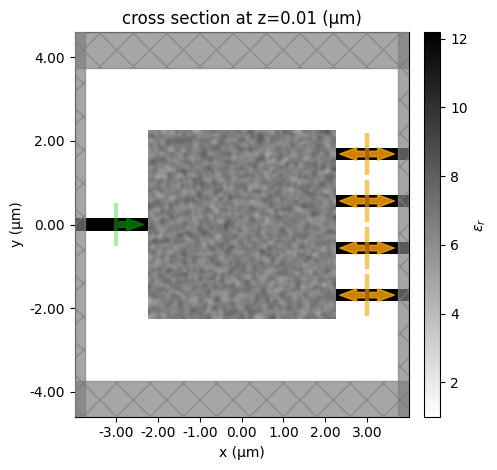

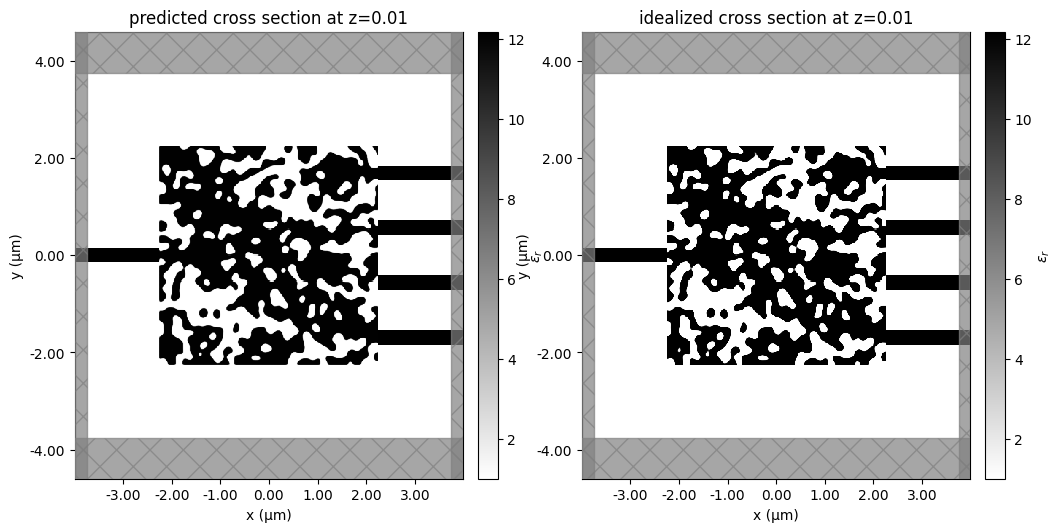

Let’s also run the final simulation with the prediction model.

[32]:

sim_final_predicted = get_sim(

params_history[iter_final], beta=beta_history[iter_final], use_predict=True

)

for i in range(num_freqs_design):

sim_final_predicted = sim_final_predicted.updated_copy(

freqs=freqs_measure, path=f"monitors/{i}"

)

sim_final_predicted = sim_final_predicted.updated_copy(

freqs=freqs_measure, path=f"monitors/{i + num_freqs_design}"

)

The predicted fabrication variations show some notable differences from the ideal design, such as the filled-in hole in the bottom left. However, most variations are quite subtle at this scale and resolution. Despite the seemingly minor geometric differences, these variations lead to meaningful changes in device performance, which we will analyze in the next section.

[33]:

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(12, 6))

sim_final_predicted.plot_eps(z=0.01, monitor_alpha=0, source_alpha=0, ax=ax1)

ax1.set_title("predicted cross section at z=0.01")

sim_final.plot_eps(z=0.01, monitor_alpha=0, source_alpha=0, ax=ax2)

ax2.set_title("idealized cross section at z=0.01")

plt.show()

[34]:

sim_data_final_predicted = web.run(

sim_final_predicted, verbose=False, task_name="wdm_final_predicted"

)

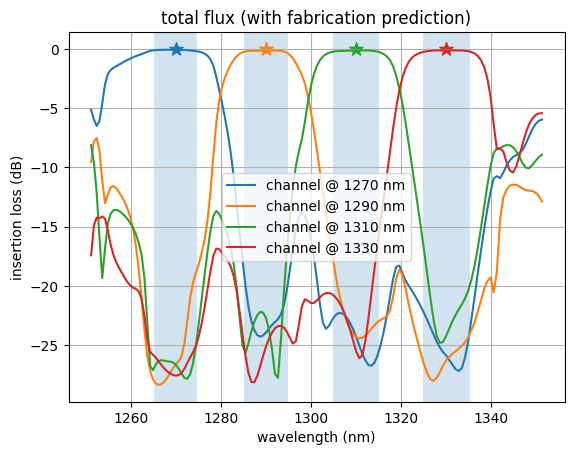

Flux#

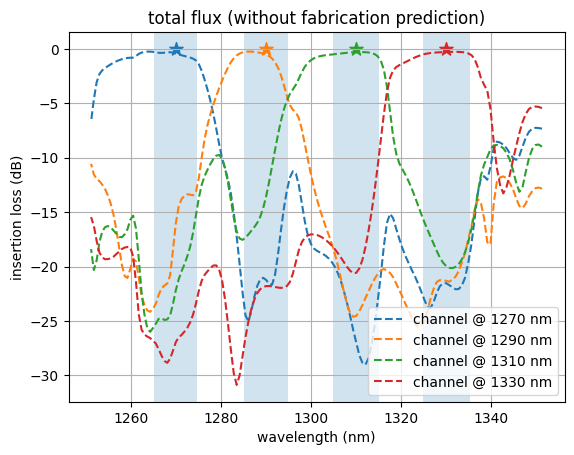

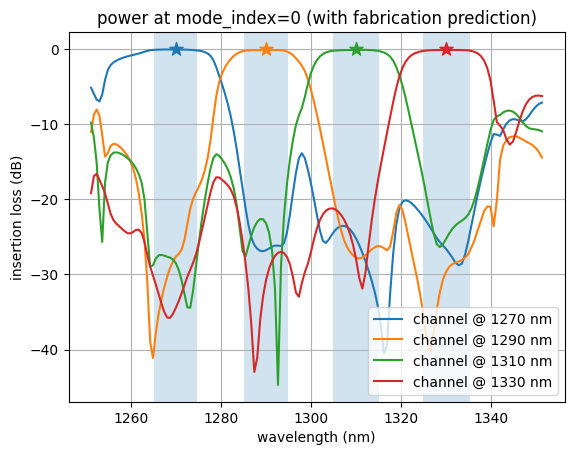

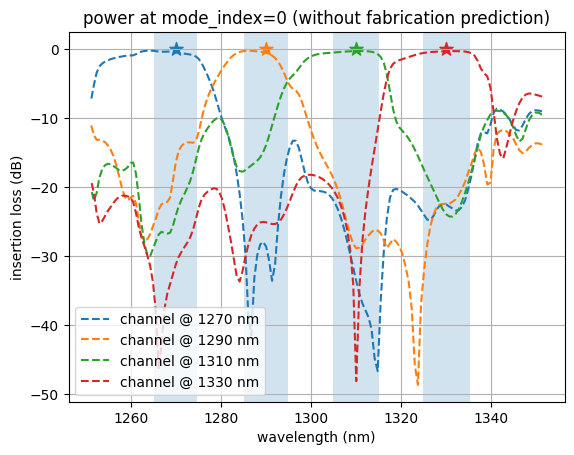

Let’s inspect the flux over each of the output ports as a function of wavelength.

We notice that the ports have peaks in transmission at their corresponding design wavelengths, and are suppressed at the other wavelengths, as expected!

For FAID: Because we optimized the design based on the fabrication-predicted geometry, we observe that the predicted design has higher performance than the final idealized design. This is intended. This contrasts with non-FAID-based optimization, where the fabrication-predicted structures typically have lower performance than the ideal design due to unaccounted fabrication variations.

[35]:

def plot_flux(sim_data, title, linestyle="-"):

for i in range(num_freqs_design):

freq = freqs_design[i]

flux_data = sim_data[mnts_flux[i].name]

wvl_nm = 1000 * td.C_0 / freq

wavelengths_nm = 1000 * td.C_0 / np.array(flux_data.flux.f)

flux = np.array(flux_data.flux.values)

loss_db = 10 * np.log10(flux)

label = f"channel @ {int(wvl_nm)} nm"

fmin, fmax = channel_bounds[i]

plt.gca().axvspan(1000 * td.C_0 / fmin, 1000 * td.C_0 / fmax, alpha=0.2)

plt.plot(wavelengths_nm, loss_db, label=label, linestyle=linestyle)

plt.scatter([wvl_nm], [0], 100, marker="*")

plt.xlabel("wavelength (nm)")

plt.ylabel("insertion loss (dB)")

plt.legend()

plt.grid("on")

plt.title(title)

plt.show()

plot_flux(sim_data_final_predicted, "total flux (with fabrication prediction)")

plot_flux(sim_data_final, "total flux (without fabrication prediction)", linestyle="--")

[36]:

def plot_power(sim_data, title, linestyle="-"):

for i in range(num_freqs_design):

freq = freqs_design[i]

amps = sim_data[mnts_mode[i].name].amps

powers = np.abs(amps.sel(direction="+", mode_index=0)) ** 2

wvl_nm = 1000 * td.C_0 / freq

flux_data = sim_data[mnts_flux[i].name]

wavelengths_nm = 1000 * td.C_0 / np.array(flux_data.flux.f)

flux = np.array(powers.values)

loss_db = 10 * np.log10(flux)

label = f"channel @ {int(wvl_nm)} nm"

fmin, fmax = channel_bounds[i]

plt.gca().axvspan(1000 * td.C_0 / fmin, 1000 * td.C_0 / fmax, alpha=0.2)

plt.plot(wavelengths_nm, loss_db, label=label, linestyle=linestyle)

plt.scatter([wvl_nm], [0], 100, marker="*")

plt.xlabel("wavelength (nm)")

plt.ylabel("insertion loss (dB)")

plt.legend()

plt.grid("on")

plt.title(title)

plt.show()

plot_power(sim_data_final_predicted, "power at mode_index=0 (with fabrication prediction)")

plot_power(

sim_data_final,

"power at mode_index=0 (without fabrication prediction)",

linestyle="--",

)

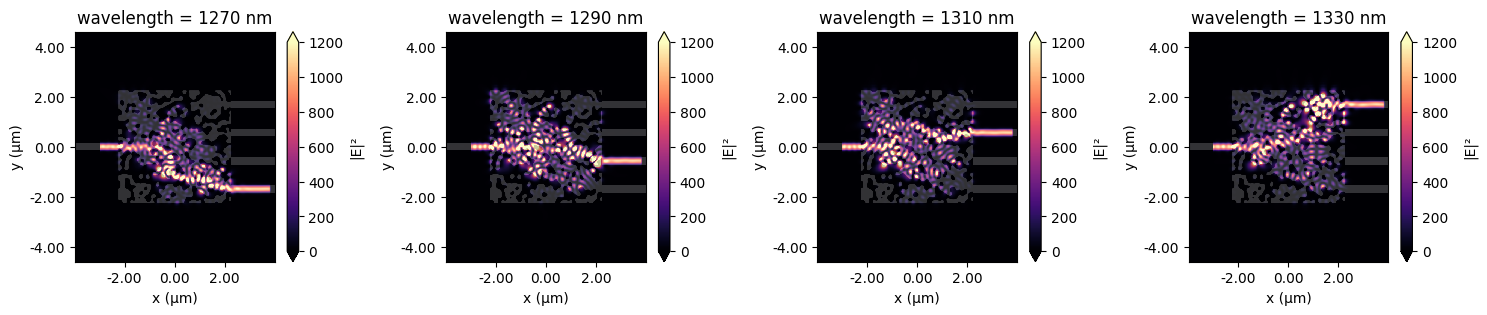

Fields#

Let’s also plot the field intensity patterns at each of the design wavelengths for the predicted design.

We see from this plot the expected result that the power is directed to the design port at each frequency.

[37]:

# plot fields at the two design wavelengths

fig, axes = plt.subplots(

1, num_freqs_design, tight_layout=True, figsize=(15, 0.8 * num_freqs_design)

)

for freq, ax in zip(freqs_design, axes):

sim_data_final_predicted.plot_field("field", "E", "abs^2", f=freq, ax=ax, vmax=1200)

wvl = 1000 * td.C_0 / freq

ax.set_title(f"wavelength = {int(wvl)} nm")

Animation#

Finally, we animate this plot as a function of iteration number. The animation shows the device quickly accomplishing our design objective.

Note: can take a few minutes to complete

[38]:

import matplotlib.animation as animation

from IPython.display import HTML

fig, ax1 = fig, axes = plt.subplots(1, 1, tight_layout=False, figsize=(9, 4))

def animate(i):

sim_i = get_sim(params_history[i], beta_history[i])

sim_i.plot_eps(z=0.01, monitor_alpha=0, source_alpha=0, ax=ax1)

ax1.set_aspect("equal")

# create animation

ani = animation.FuncAnimation(fig, animate, frames=len(beta_history))

plt.close()

[39]:

# display the animation (press "play" to start)

HTML(ani.to_jshtml())

[39]:

<Figure size 640x480 with 0 Axes>

To save the animation as a file, uncomment the line below

Note: can take several more minutes to complete

[40]:

# ani.save("img/animation_wdm_autograd.gif", fps=30)

Export to GDS#

The Simulation object has the .to_gds_file convenience function to export the final design to a GDS file. In addition to a file name, it is necessary to set a cross-sectional plane (z = 0 in this case) on which to evaluate the geometry, a frequency to evaluate the permittivity, and a permittivity_threshold to define the shape boundaries in custom

mediums. See the GDS export notebook for a detailed example on using .to_gds_file and other GDS related functions.

For FAID: Even though we optimize based on the predicted (fabricated) structure, we export the final idealized (not predicted) design. By accounting for fabrication imperfections during optimization, we aim for the structure that is ultimately fabricated to perform at its best.

[41]:

# sim_final.to_gds_file(

# fname="./misc/inv_des_wdm_ag_FAID.gds",

# z=0,

# permittivity_threshold=(n_si**2 + 1) / 2,

# frequency=freq0,

# )

[ ]: