Transition Model 2D Airfoil#

This notebook sets up, runs, and post-processes a steady Flow360 simulation of a 2D airfoil with a transition model.

1. Create Project from Volume Mesh#

We initialize a Flow360 project by uploading an existing CGNS volume mesh, which becomes the VolumeMesh for this simulation.

[1]:

import flow360 as fl

from flow360.examples import NLFAirfoil2D

NLFAirfoil2D.get_files()

project = fl.Project.from_volume_mesh(

NLFAirfoil2D.mesh_filename, name="Transition Model 2D Airfoil from Python"

)

vm = project.volume_mesh

[21:19:25] INFO: VolumeMesh successfully submitted: type = Volume Mesh name = Transition Model 2D Airfoil from Python id = vm-b259b45a-653b-404b-afb4-8195ebbd026f status = uploaded project id = prj-df6618e1-487a-4f73-8ffd-da7a776b2953

2. Operating Conditions and Time Settings#

We define the freestream Mach, Reynolds number, temperature, and angle of attack, then choose a steady time-stepping scheme with adaptive CFL for convergence. When using the transition model, more steps are needed to converge the flowfield due to the moving location of the transition location. This is the reason for such high number of steps and the higher convergence_limiting_factor of 0.4 which allows faster convergence while still using the adaptive CFL settings.

[2]:

operating_condition = fl.AerospaceCondition.from_mach_reynolds(

mach=0.1,

reynolds_mesh_unit=4e6,

project_length_unit=project.length_unit,

temperature=540.0 * fl.u.R,

alpha=0.0 * fl.u.deg,

)

time_stepping = fl.Steady(

max_steps=20000, CFL=fl.AdaptiveCFL(convergence_limiting_factor=0.4)

)

[21:19:47] INFO: Density and viscosity were calculated based on input data, ThermalState will be automatically created.

3. Transition Model#

We configure the transition model solver, choosing linear solver iterations, tight tolerances, and the critical amplification factor N_crit that controls transition onset. The Jacobian and equation evaluation frequencies control how often these operators are rebuilt, balancing robustness against computational cost.

[3]:

transition_model_solver = fl.TransitionModelSolver(

linear_solver=fl.LinearSolver(max_iterations=30),

absolute_tolerance=1e-10,

N_crit=7.2,

update_jacobian_frequency=1,

equation_evaluation_frequency=1,

)

4. Outputs#

We request surface and slice outputs so that Flow360 saves pressure, skin-friction, y-plus, and related fields needed for later analysis around the airfoil.

[4]:

outputs = [

fl.SurfaceOutput(

surfaces=vm["Block/Aerofoil"],

output_format="both",

output_fields=["Cp", "Cf", "yPlus", "CfVec"],

),

fl.SurfaceSliceOutput(

name="surface_slices",

entities=[fl.Slice(name="y", normal=(0, 1, 0), origin=(0, -0.5, 0) * fl.u.m)],

target_surfaces=vm["Block/Aerofoil"],

output_format="paraview",

output_fields=["Cp", "Cf", "yPlus", "CfVec"],

),

]

5. Define SimulationParams#

We assemble operating conditions, time stepping, boundary condition models, solvers, and outputs into a single SimulationParams object used to run the case.

[5]:

with fl.SI_unit_system:

params = fl.SimulationParams(

operating_condition=operating_condition,

time_stepping=time_stepping,

models=[

fl.Wall(

surfaces=vm["Block/Aerofoil"],

),

fl.Freestream(

surfaces=vm["Block/Farfield"],

),

fl.SlipWall(entities=[vm["Block/Symmetry"]]),

fl.Fluid(

turbulence_model_solver=fl.SpalartAllmaras(

absolute_tolerance=1e-10,

linear_solver=fl.LinearSolver(max_iterations=30),

update_jacobian_frequency=1,

equation_evaluation_frequency=1,

),

navier_stokes_solver=fl.NavierStokesSolver(

linear_solver=fl.LinearSolver(max_iterations=50),

absolute_tolerance=1e-12,

update_jacobian_frequency=4,

equation_evaluation_frequency=1,

),

transition_model_solver=transition_model_solver,

),

],

outputs=outputs,

)

INFO: using: SI unit system for unit inference.

6. Run Case#

We submit the configured simulation to Flow360, creating a case on the server that runs using the project, parameters, and models defined above.

[6]:

case = project.run_case(params=params, name="Transition Model 2D Airfoil from Python")

INFO: Density and viscosity were calculated based on input data, ThermalState will be automatically created.

INFO: using: SI unit system for unit inference.

[21:19:49] INFO: Successfully submitted: type = Case name = Transition Model 2D Airfoil from Python id = case-11767f48-bb81-412f-aec0-70494c03fd78 status = pending project id = prj-df6618e1-487a-4f73-8ffd-da7a776b2953

7. Post Processing#

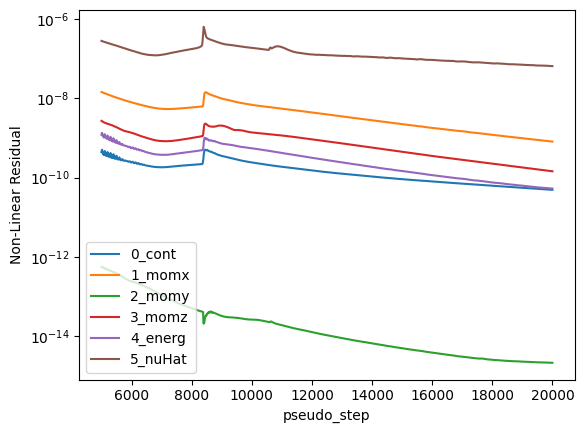

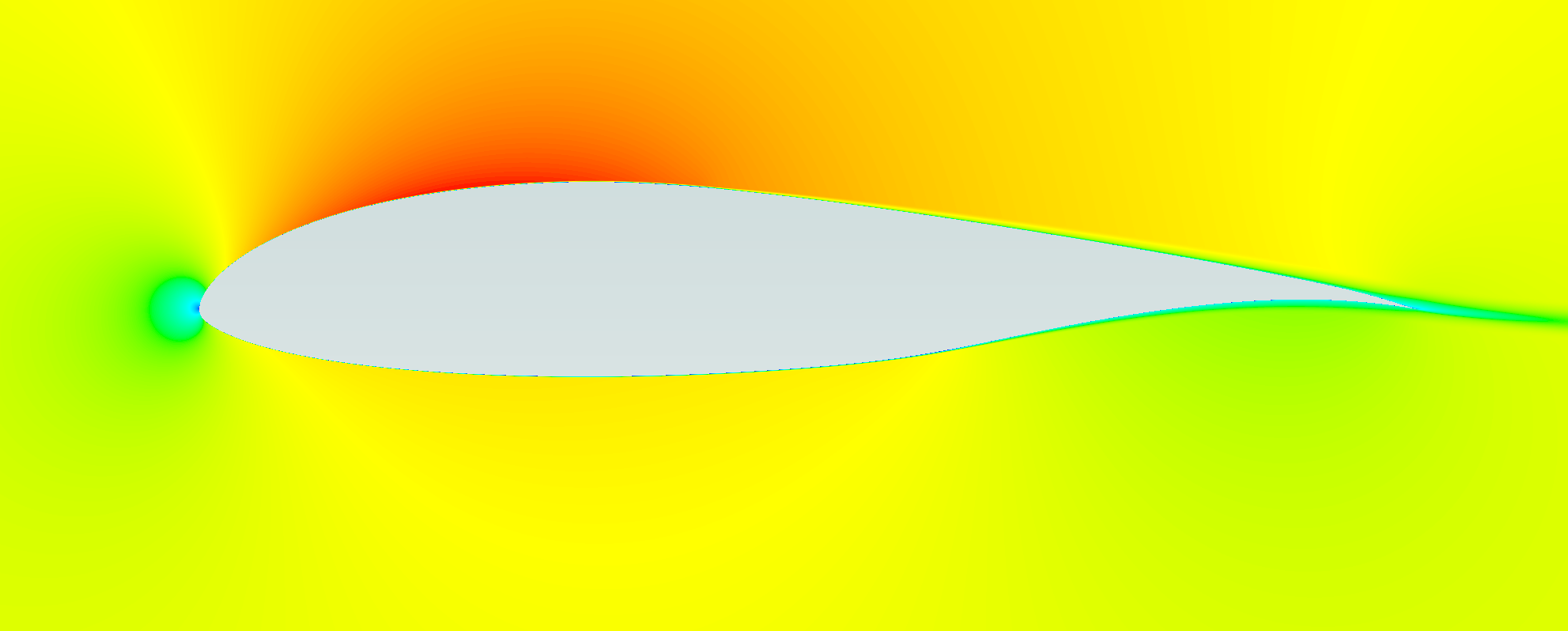

After the case finishes, we download surface data, compute integrated forces, inspect residual histories, and visualize the friction coefficient distribution over the airfoil.

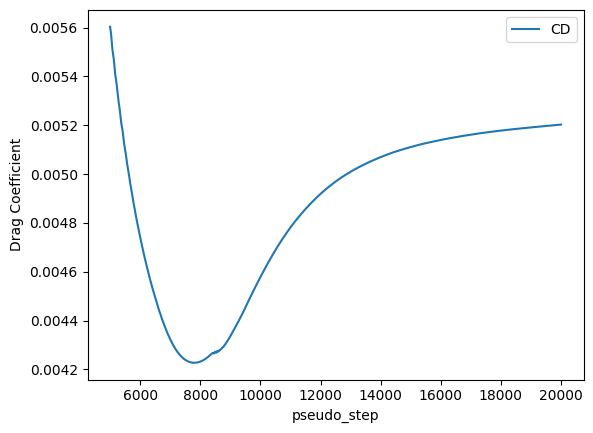

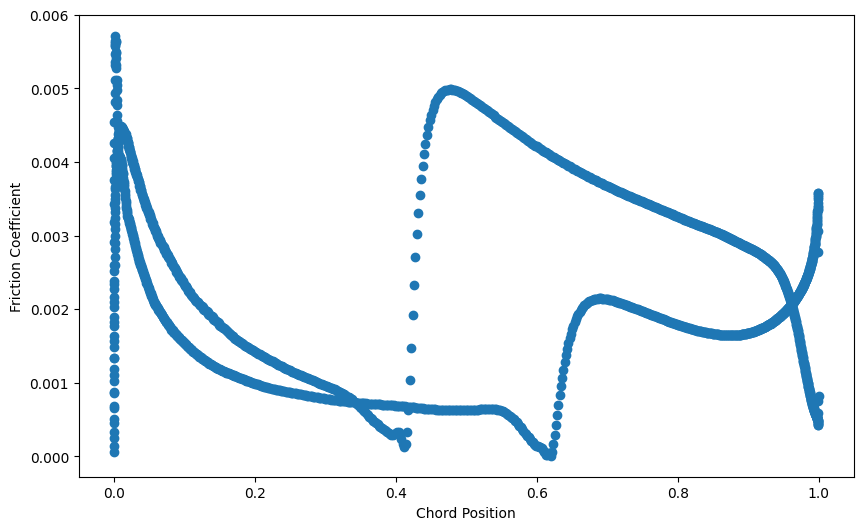

Notice that the drag coefficient reaches a pseudo step where it increases again due to more length modelled as turbulent boundary layer. Maybe it wwould be good to run even longer for full convergence but for the sake of this example it is not needed. Finally, from the surface slices, we can plot the friction coefficient. We observe the transition locations both at the pressure and suction sides where the friction coefficient increases significnatly.

[7]:

import tempfile

import os

import tarfile

import pyvista as pv

import matplotlib.pyplot as plt

def extract_results(results):

with tempfile.TemporaryDirectory() as temp_dir:

destination = os.path.join(temp_dir, "case_data")

os.makedirs(destination, exist_ok=True)

results.download(

surface=True,

destination=destination,

)

surfaces_path = os.path.join(destination, "surfaces.tar.gz")

with tarfile.open(surfaces_path) as tar:

tar.extractall(path=temp_dir) # extract directly into temp_dir

mesh_path = os.path.join(temp_dir, "surface_slice_y.pvtu")

mesh = pv.read(mesh_path)

x = mesh.points[:, 0]

y = mesh.points[:, 1]

z = mesh.points[:, 2]

cf = mesh.point_data["Cf"]

cp = mesh.point_data["Cp"]

# Sort based on x-direction

sorted_indices = x.argsort()

x = x[sorted_indices]

y = y[sorted_indices]

z = z[sorted_indices]

cf = cf[sorted_indices]

cp = cp[sorted_indices]

return x, y, z, cf, cp

case.wait()

results = case.results

total_forces = results.total_forces.as_dataframe()

total_forces_filtered = total_forces[total_forces["pseudo_step"] >= 5000]

total_forces_filtered.plot("pseudo_step", ["CD"])

plt.ylabel("Drag Coefficient")

non_linear = results.nonlinear_residuals.as_dataframe()

non_linear_filtered = non_linear[non_linear["pseudo_step"] >= 5000]

non_linear_filtered.plot(

"pseudo_step",

["0_cont", "1_momx", "2_momy", "3_momz", "4_energ", "5_nuHat"],

logy=True,

)

plt.ylabel("Non-Linear Residual")

# Plot friction coefficient

x, y, z, cf, cp = extract_results(results)

plt.figure(figsize=(10, 6))

plt.scatter(x, cf, label="Friction Coefficient")

plt.xlabel("Chord Position")

plt.ylabel("Friction Coefficient")

[21:33:46] INFO: Saved to /tmp/tmpx7ap3xst/9a2f753c-4dae-4e33-889e-c77f87b39ba2.csv

[21:33:48] INFO: Saved to /tmp/tmpx7ap3xst/5d294f90-0649-4a93-ba55-74a682e44972.csv

[21:33:50] INFO: Saved to /tmp/tmpkjcvuse8/case_data/surfaces.tar.gz

[7]:

Text(0, 0.5, 'Friction Coefficient')