Custom Model¶

PhotonForge provides a large number of models, particularly for passive optical devices. However, custom models can be easily implemented for specific use-cases. This short guide provides an example of custom model implementation for a voltage-controlled phase-shifter, that could be used in the Tunable MZI and the Switch Array examples.

The phase-shifter is based on a WaveguideModel with propagation index modeled as:

in which \(V\) is the applied voltage, \(\gamma\) is a coefficient that relates the variation of the index with the squared voltage.

This model could be applied to a thermo-optic phase-shifter, where the temperature in the thermal element is proportional to the input electrical power (thus squared voltage) and the coefficient depends on the overall geometry and materials. It can be calculated using a heat simulation, but we will skip that step to keep this guide short.

Any custom model must be derived from the base Model class and implement the start method. This guide will implement it alongside a proper __init__ to provide a full reference for other models, but the source code for all PhotonForge models is also available in our docs.

[1]:

import numpy as np

import photonforge as pf

Class initialization¶

The __init__ method must call super().__init__ with all user-provided arguments. That ensures the parametric_kwargs attribute of all instances is properly initialized, and they can be later used as parametric models and updated when necessary.

During circuit simulations or Monte Carlo runs, models can be updated (for example, through the updates parameter in CircuitModel.start). When that happens, the model is recreated from its (updated) parametric keyword arguments, so any changes to the model made after creation are lost. That means that model state should only be set

in the __init__ method.

Here’s what NOT to do:

[2]:

class BadModel(pf.Model):

def __init__(self, a=0, b=1):

super().__init__(a=a) # ERROR: missing parameter b

self.a = a

self.b = b

self.abc = 0

def set_c(self, c):

self.abc = self.a * self.b * c # ERROR: this change will vanish after update

def start(self):

pass

bad_model = BadModel(a=1, b=2)

print(f"Note the missing parameter 'b': {bad_model.parametric_kwargs=}")

Note the missing parameter 'b': bad_model.parametric_kwargs={'a': 1}

[3]:

bad_model.set_c(3)

print(f"""New model state {bad_model.abc=}

But no changes in the 'parametric_kwargs' dictionary: {bad_model.parametric_kwargs=}""")

New model state bad_model.abc=6

But no changes in the 'parametric_kwargs' dictionary: bad_model.parametric_kwargs={'a': 1}

[4]:

bad_model.update(a=10)

print(f"""Updated parameter 'a': {bad_model.a=}

Parameter 'b' should not be updated, but lost its original value (2): {bad_model.b=}

Call to 'set_c' forgotten: {bad_model.abc=}""")

Updated parameter 'a': bad_model.a=10

Parameter 'b' should not be updated, but lost its original value (2): bad_model.b=1

Call to 'set_c' forgotten: bad_model.abc=0

A better way to implement the same model would be to remove the state change from outside the __init__ method, and refactor the internal state as a property calculated when needed:

[5]:

class GoodModel(pf.Model):

def __init__(self, a=0, b=0, c=0):

super().__init__(a=a, b=b, c=c) # All state as __init__ arguments

@property

def abc(self):

p = self.parametric_kwargs

return p["a"] * p["b"] * p["c"]

def start(self):

pass

good_model = GoodModel(a=1, b=2)

print(f"All paramters properly initialized: {good_model.parametric_kwargs=}")

# Use update to set new value

good_model.update(c=3)

print(f"""Updated 'parametric_kwargs' dictionary: {good_model.parametric_kwargs}

New model state {good_model.abc=}""")

good_model.update(a=10)

print(f"""Updated 'parametric_kwargs' dictionary: {good_model.parametric_kwargs}

New model state {good_model.abc=}""")

All paramters properly initialized: good_model.parametric_kwargs={'a': 1, 'b': 2, 'c': 0}

Updated 'parametric_kwargs' dictionary: {'a': 1, 'b': 2, 'c': 3}

New model state good_model.abc=6

Updated 'parametric_kwargs' dictionary: {'a': 10, 'b': 2, 'c': 3}

New model state good_model.abc=60

S-matrix computation¶

We must provide a way for our custom model to actually compute the S matrix for a given component. That is done in the start method.

The start method will receive keyword arguments passed to call to the model or component s_matrix method through the model_kwargs argument. For this model, we want to accept a voltage value that overrides the internal voltage and allows us to set it dynamically.

For this model, we will leverage the existing WaveguideModel to perform the actual computation based on the calculated propagation constant.

Alternatively, we could perform the computation in the function itself and return the resulting SMatrix. If the computation is a long process, the start method can be used to simply kick it off and return an object that can be used to monitor the computation progress, but that will be left for another guide.

Full implemetation¶

Putting it all together, we have the following implementation.

It is paramount to register the custom model class after creating it, otherwise PhotonForge won’t be able to use it automatically.

[6]:

class ThermalModel(pf.Model):

def __init__(self, n_complex, voltage=0, coefficient=3e-4):

super().__init__(

n_complex=n_complex,

voltage=voltage,

coefficient=coefficient,

)

@pf.cache_s_matrix

def start(self, component, frequencies, voltage=None, **kwargs):

p = self.parametric_kwargs

# Use voltage as an `s_matrix` kwarg, but fallack to default value

if voltage is None:

voltage = p["voltage"]

# Main model equation

n_complex = p["n_complex"] + p["coefficient"] * voltage**2

# Auxiliary model for the computation

wg_model = pf.WaveguideModel(n_complex)

return wg_model.start(component, frequencies, **kwargs)

pf.register_model_class(ThermalModel)

Usage Example: Tunable Microring Resonator¶

We start by configuring the simulation environment

We assign the basic photonforge technology to

pf.config.default_technology.We define default keyword arguments for our components, specifying a

"Strip"port and a radius of10.We define the wavelength range.

[7]:

import matplotlib.pyplot as plt

from photonforge.live_viewer import LiveViewer

viewer = LiveViewer(port=5013)

# Set default technology to the basic technology provided by photonforge

pf.config.default_technology = pf.basic_technology()

# Set default keyword arguments for simulations: use Strip port specification and radius of 10

pf.config.default_kwargs = {"port_spec": "Strip", "radius": 10}

# Define wavelength range for the simulation (in micrometers)

wavelengths = np.linspace(1.546, 1.548, 201)

# Convert wavelengths to frequencies (Hz) using speed of light constant

frequencies = pf.C_0 / wavelengths

LiveViewer started at http://localhost:5013

Coupler Definition¶

We now define the directional coupler that will be used to couple light into and out of the microring:

We create a dual-ring directional coupler with a waveguide gap of

0.9 µmand a coupling region length of10 µm.We set the

Tidy3Dgrid specification to12to reduce simulation cost but with reasonable accuracy.

[8]:

# Set the coupling length for the directional coupler

coupling_length = 10

# Define a dual-ring directional coupler with specified geometry and waveguide spacing

dc_coupler = pf.parametric.ring_coupler(

coupling_distance=0.9, # distance between the coupled waveguides (µm)

coupling_length=coupling_length, # coupling region length (µm)

model=pf.Tidy3DModel(grid_spec=12),

)

# Display the coupler layout

viewer(dc_coupler)

[8]:

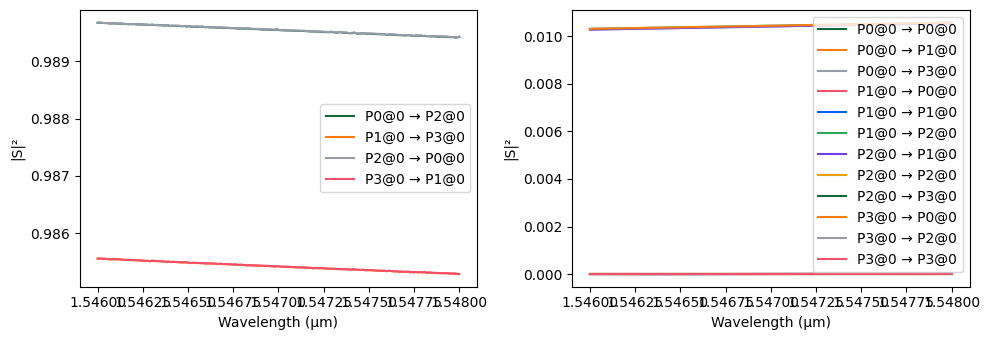

The coupler has been designed to achieve approximately 1% power coupling between the waveguides. We simulate the S-matrix of the directional coupler over the defined frequency range. The resulting plot confirms the low coupling regime, with around 1% of power transferred between ports.

[9]:

# Compute the S-matrix of the dual-ring coupler over the specified frequencies

s_matrix_dc = dc_coupler.s_matrix(frequencies)

_ = pf.plot_s_matrix(s_matrix_dc)

Starting…

05:31:06 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-340ada4a-a1e 4-498b-817f-6c639c3f0408'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-8fb2ebb5-137 2-4aef-afdc-146f06ccb8ff'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-90a01c07-12a e-4823-a31f-a78ed5c6bafa'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-43c39d47-9bc 7-4c0b-81b3-570603099be0'.

Progress: 100%

Waveguide with Thermal Model¶

Next, we define the straight waveguide section and place a metal heater on top:

We use a propagation loss, converted to an imaginary part of the refractive index (

kappa) for accurate modeling.A heater is designed using a tapered metal path, consisting of wide pads and a narrow central section.

This heater is positioned on top of the waveguide.

We solve the port mode to get the base complex index and add loss by modifying the imaginary part.

A custom

ThermalModelis instantiated with this lossy refractive index, and added to the waveguide.Finally, we visualize the structure including the integrated heater.

[10]:

# Set propagation loss in dB/cm

alpha = 10

# Define metal heater geometry

heater_width = 5

pad_width = 20

transition_length = 10

# Calculate imaginary part of refractive index due to propagation loss

kappa = (alpha * wavelengths * 1e-4 * np.log(10)) / (40 * np.pi)

# Create the waveguide geometry with length equal to the coupler

wg = pf.parametric.straight(length=coupling_length)

# Define the heater path with tapered metal pads and narrow central section

heater = (

pf.Path((-2 * transition_length - pad_width, 0), pad_width)

.segment((-2 * transition_length, 0), pad_width)

.segment((-transition_length, 0), heater_width)

.segment((coupling_length + transition_length, 0))

.segment((coupling_length + 2 * transition_length, 0), pad_width)

.segment((coupling_length + 2 * transition_length + pad_width, 0), pad_width)

)

# Attach the metal heater to the waveguide

wg.add((5, 0), heater)

# Solve for the port mode of the waveguide and extract the complex refractive index

mode_solver = pf.port_modes(port=wg.ports["P0"], frequencies=frequencies)

n_complex = mode_solver.data.n_complex.values.T + 1j * kappa # add propagation loss

# Instantiate a thermal model using the lossy index

thermal_model = ThermalModel(n_complex=n_complex)

# Attach the thermal model to the waveguide

wg.add_model(thermal_model, "Thermal")

# Visualize the waveguide and heater

viewer(wg)

Starting…

05:31:07 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-a1e291a3-849f- 4aee-858b-75d7c1bb2cbe'.

Progress: 100%

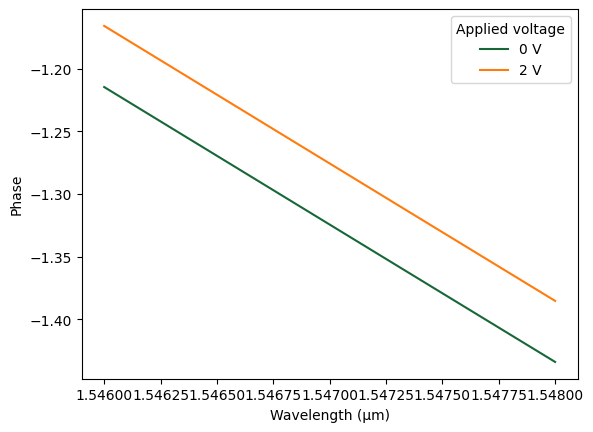

[10]:

Before assembling the full circuit, we test the thermal model directly on the waveguide. We compute the S-matrix at 0 V and 2 V to observe the phase change. The phase shift of the S21 response is plotted as a function of wavelength. This confirms that the custom thermal model applies a voltage-dependent phase shift, as expected.

[11]:

# Compute S-matrix for the waveguide with no voltage applied

s_v0 = wg.s_matrix(frequencies)

# Compute S-matrix with 2 V applied to the thermal model

s_v2 = wg.s_matrix(frequencies, model_kwargs={"voltage": 2})

# Plot the phase response (angle of S21) for both voltages

plt.plot(wavelengths, np.angle(s_v0[("P0@0", "P1@0")]), label="0 V")

plt.plot(wavelengths, np.angle(s_v2[("P0@0", "P1@0")]), label="2 V")

# Label the axes

plt.xlabel("Wavelength (µm)")

plt.ylabel("Phase")

# Add legend to differentiate voltage levels

plt.legend(title="Applied voltage")

# Display the plot

plt.show()

Progress: 100%

Progress: 100%

To ensure consistency across the layout, we also assign the same lossy refractive index to a waveguide bend:

[12]:

# Create a bend waveguide using default parameters

bend = pf.parametric.bend(model=pf.WaveguideModel(n_complex=n_complex))

# Visualize the bend structure

viewer(bend)

[12]:

Tunable Microring Resonator Construction¶

We now build a tunable microring resonator by connecting the previously defined components:

The

netlistdefines each component: a directional coupler (dc), a phase shifter (ps), and two bends (b0andb1).These components are connected in a loop to form the microring structure.

External ports are exposed on the input and output sides of the directional coupler.

A

CircuitModelis assigned to handle simulation of the entire system.Finally, we use

component_from_netlistto construct the full microring resonator.

[13]:

# Define the netlist for a tunable microring resonator

netlist_mrr = {

"name": "Tunable Microring Resonator", # name of the component

"instances": {

"dc": dc_coupler, # directional coupler

"ps": wg, # waveguide with heater (phase shifter)

"b0": bend,

"b1": bend,

},

# Define how components are connected

"connections": [

(("b0", "P1"), ("dc", "P1")), # connect top bend to one side of the coupler

(("b1", "P0"), ("dc", "P3")), # connect bottom bend to the other side

(("ps", "P0"), ("b0", "P0")), # connect phase shifter to top bend

],

# Define external ports (input and output)

"ports": [("dc", "P0"), ("dc", "P2")],

# Assign a CircuitModel to simulate the entire microring

"models": [(pf.CircuitModel(), "Circuit")],

}

# Build the microring resonator from the netlist

mrr = pf.component_from_netlist(netlist_mrr)

# Visualize the resulting component

viewer(mrr)

[13]:

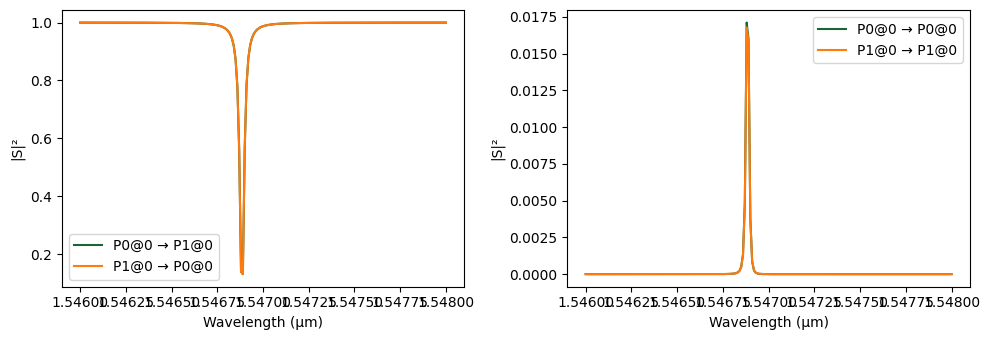

[14]:

# Compute the S-matrix of the full circuit

s_matrix = mrr.s_matrix(frequencies)

# Plot transmission

fig, ax = pf.plot_s_matrix(s_matrix)

Starting…

05:31:12 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-496ac81e-4b03- 4c73-931b-6dbc8a025a8b'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-eeaa9eb5-7f1a- 4580-8306-05da1901615b'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-3dfe0cf4-e505- 4ac0-ae13-4f0e1c3f3d11'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-38a3cca4-4f62- 4732-b185-3d6ece5650e8'.

Progress: 100%

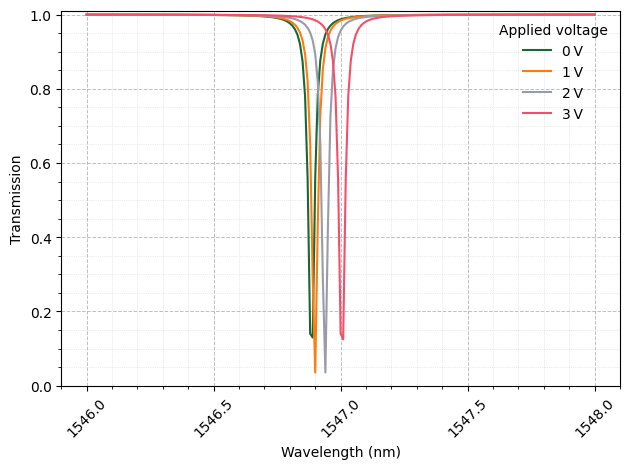

Resonance Tuning via Applied Voltage¶

To observe how the microring’s resonance shifts under different voltages:

We sweep the applied voltage across the waveguide heater with values of

0 V,2 V, and3 V.For each voltage, we simulate the S-matrix and extract the transmission (

S21).The transmission spectra are plotted against wavelength in nanometers.

The resonance shift is clearly visible, confirming the thermo-optic tuning effect of the microring.

💡 Reference indexing: When updating model parameters during S-matrix simulation, we use the syntax

(component_name, reference_index). This allows precise control when the same component appears multiple times within a larger layout. For example,(wg.name, 0)refers to the first reference of thewgcomponent inside themrr. If there were multiple uses ofwg, we could address and update each independently by changing the index.

[15]:

import matplotlib.ticker as ticker

# the list of voltages

voltages = [0, 1, 2, 3]

# make one figure/axes

fig, ax = plt.subplots()

for v in voltages:

updates = {(wg.name, 0): {"model_updates": {"voltage": v}}}

s_matrix = mrr.s_matrix(frequencies, model_kwargs={"updates": updates})

s21 = s_matrix[("P0@0", "P1@0")]

ax.plot(

wavelengths * 1e3,

np.abs(s21) ** 2,

label=f"{v} V",

linewidth=1.5,

)

# labels & legend

ax.set_xlabel("Wavelength (nm)")

ax.set_ylabel("Transmission")

ax.set_ylim(0, 1.01)

ax.legend(title="Applied voltage", loc="upper right", frameon=False)

# major ticks every 0.5 nm, minor ticks every 0.1 nm

ax.xaxis.set_major_locator(ticker.MultipleLocator(0.5))

ax.xaxis.set_minor_locator(ticker.MultipleLocator(0.1))

ax.xaxis.set_major_formatter(ticker.FormatStrFormatter("%.1f"))

# y‑axis major ticks every 0.2, minor every 0.05

ax.yaxis.set_major_locator(ticker.MultipleLocator(0.2))

ax.yaxis.set_minor_locator(ticker.MultipleLocator(0.05))

# enable both major & minor gridlines

ax.grid(which="major", linestyle="--", linewidth=0.7, alpha=0.8)

ax.grid(which="minor", linestyle=":", linewidth=0.5, alpha=0.5)

# rotate x‑labels for readability

plt.setp(ax.get_xticklabels(which="major"), rotation=45)

plt.tight_layout()

plt.show()

Progress: 100%

Progress: 100%

Progress: 100%

Progress: 100%