BTO Electro-Optic Modulator¶

In this notebook, we simulate the product of the half-wave voltage (\(V_\pi\)) and the interaction length (\(L\)) for a BTO electro-optic modulator [1]. This is a key performance metric for evaluating the modulation efficiency of electro-optic modulators.

References

Han, Huangpu, et al. “Integrated barium titanate electro-optic modulators operating at CMOS-compatible voltage.” Applied Optics 2023, 62 (22), 6053–6059. doi: 10.1364/AO.499065

[1]:

import matplotlib.pyplot as plt

import numpy as np

import photonforge as pf

import tidy3d as td

First, we define the key geometric parameters of the coplanar waveguide (CPW) used in the BTO modulator structure.

[2]:

signal_width = 3.8 # Width of the CPW signal electrode (µm)

gap_width = 4.4 # Gap width between signal and ground electrodes (µm)

ground_width = 40 # Width of the CPW ground electrode (µm)

These parameters define the technology stack and material dimensions for the thin-film BTO electro-optical modulator

[3]:

bto_thickness = 0.5 # Thickness of the BTO waveguide core layer (µm)

slab_thickness = 0.25 # Thickness of the BTO slab layer surrounding the core (µm)

box_thickness = 2 # Thickness of the buried oxide (BOX) layer (µm)

tl_thickness = 0.8 # Thickness of the metal transmission line (TL) layer (µm)

tl_separation = 0 # Vertical separation between TL and BTO slab (µm)

sidewall_angle = 0 # Sidewall angle of etched BTO waveguide (degrees)

lambda_0 = 1.55 # Operating wavelength (µm)

Technology Definition¶

The custom_bto_pdk function creates a customizable technology definition for photonic circuit design using a thin-film BTO platform. It includes detailed specifications for material properties, geometric layers, and cross-sectional configurations. Users can precisely control parameters such as BTO core thickness, slab thickness, oxide cladding layers, metallic transmission lines, sidewall angles, and substrate inclusion.

[4]:

_Medium = td.components.medium.MediumType

@pf.parametric_technology

def custom_bto_pdk(

*,

bto_thickness: float = 0.5,

slab_thickness: float = 0.25,

sidewall_angle: float = 0,

box_thickness: float = 2,

tl_thickness: float = 0.8,

tl_separation: float = 0,

include_substrate: bool = True,

include_top_opening: bool = True,

sio2: dict[str, _Medium] = {

"optical": td.material_library["SiO2"]["Palik_Lossless"],

"electrical": td.Medium(permittivity=3.9, name="SiO2"),

},

si: dict[str, _Medium] = {

"optical": td.material_library["cSi"]["Li1993_293K"],

"electrical": td.Medium(permittivity=11.7, name="Si"),

},

bto: dict[str, _Medium] = {

"optical": td.AnisotropicMedium(

xx=td.Medium(permittivity=2.312**2),

yy=td.Medium(permittivity=2.274**2),

zz=td.Medium(permittivity=2.312**2),

),

"electrical": td.AnisotropicMedium(

xx=td.Medium(permittivity=3000),

yy=td.Medium(permittivity=60),

zz=td.Medium(permittivity=3000),

),

},

tl_metal: dict[str, _Medium] = {

"optical": td.material_library["Au"]["JohnsonChristy1972"],

"electrical": td.LossyMetalMedium(

conductivity=41,

frequency_range=[0.1e9, 300e9],

fit_param=td.SurfaceImpedanceFitterParam(max_num_poles=16),

),

},

air: _Medium = td.Medium(permittivity=1.0, name="Air"),

) -> pf.Technology:

"""Create a thin-film Barium Titanate technology.

Args:

bto_thickness (float): BTO layer thickness.

slab_thickness (float): Partially etched slab thickness in BTO.

sidewall_angle (float): Sidewall angle (in degrees) for BTO etching.

box_thickness (float): Thickness of the bottom oxide clad.

tl_thickness (float): TL layer thickness.

tl_separation (float): Separation between the slab BTO and TL layers.

include_substrate (bool): Flag indicating whether or not to include

the silicon substrate.

include_top_opening (bool): Flag indicating whether or not to

include the open region above the last extrusion layer.

sio2 (Medium): Oxide and background medium.

si (Medium): Silicon medium.

bto (Medium): BTO medium.

tl_metal (Medium): TL metal medium.

air (Medium): Air medium.

Returns:

Technology: Parametric technology object for BTO-based PDK.

"""

# Layers

layers = {

"BTO_RIDGE": pf.LayerSpec(

layer=(2, 0),

description="BTO etch (ridge)",

color="#7d57de18",

pattern="//",

),

"BTO_SLAB": pf.LayerSpec(

layer=(3, 0), description="BTO etch (full)", color="#00008018", pattern="\\"

),

"SLAB_NEGATIVE": pf.LayerSpec(

layer=(3, 1),

description="Slab etch negative",

color="#6750bf18",

pattern="\\",

),

"MET": pf.LayerSpec(

layer=(21, 0),

description="Metal transmission lines",

color="#eadb0718",

pattern="\\",

),

}

# Extrusion specifications

bounds = pf.MaskSpec() # Empty mask for all chip bounds

full_bto_mask = pf.MaskSpec((2, 0))

slab_etch_mask = pf.MaskSpec((3, 1), (3, 0), "-")

met_mask = pf.MaskSpec((21, 0))

z_tl = slab_thickness + tl_separation

z_top = bto_thickness

extrusion_specs = [

pf.ExtrusionSpec(bounds, bto, (0, slab_thickness), 0),

pf.ExtrusionSpec(full_bto_mask, bto, (0, bto_thickness), sidewall_angle),

pf.ExtrusionSpec(slab_etch_mask, air, (0, bto_thickness), -sidewall_angle),

pf.ExtrusionSpec(met_mask, tl_metal, (z_tl, z_tl + tl_thickness)),

pf.ExtrusionSpec(bounds, sio2, (-box_thickness, 0)),

]

if include_substrate:

extrusion_specs.append(

pf.ExtrusionSpec(bounds, si, (-pf.Z_INF, -box_thickness))

)

rwg_port_gap = min(1.5, box_thickness)

rwg_port_limits = (-rwg_port_gap, bto_thickness + rwg_port_gap)

technology = pf.Technology(

"Custom BTO PDK", "1.0", layers, extrusion_specs, {}, air

)

technology.ports = {

"RWG800": pf.PortSpec(

description="BTO single mode ridge waveguide for C-band, TE mode",

width=5,

limits=rwg_port_limits,

num_modes=1,

target_neff=2.2,

path_profiles=((0.8, 0, (2, 0)), (10, 0, (3, 0))),

),

"UniCPW": pf.cpw_spec(

layer=(21, 0),

signal_width=3.8,

gap=4.4,

ground_width=250,

added_solver_modes=0,

target_neff=2.2,

technology=technology,

),

}

return technology

Now, we define the technology (tech) using our specified parameters and set it as the default for subsequent simulations and designs.

[5]:

tech = custom_bto_pdk(

bto_thickness=bto_thickness,

slab_thickness=slab_thickness,

sidewall_angle=sidewall_angle,

box_thickness=box_thickness,

tl_thickness=tl_thickness,

tl_separation=tl_separation,

)

pf.config.default_technology = tech

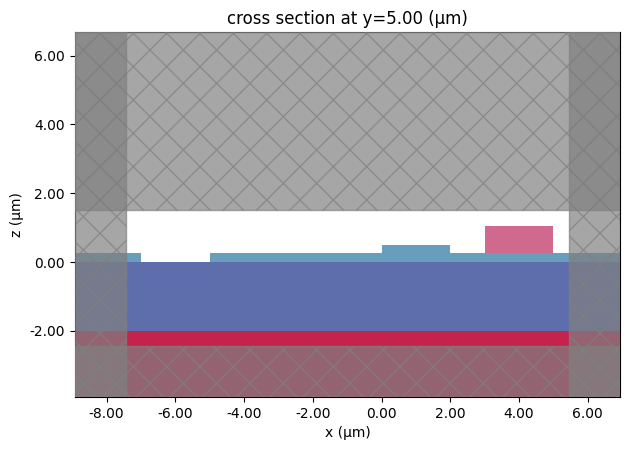

To visualize how each layer is extruded in our defined technology, we create a simple test component (test_component) that includes representative rectangles for each technology layer.

[6]:

test_component = pf.Component("test")

test_component.add(

"BTO_RIDGE",

pf.Rectangle((0, 0), (2, 10)),

"MET",

pf.Rectangle((3, 0), (5, 10)),

"SLAB_NEGATIVE",

pf.Rectangle((-7, 0), (-4, 10)),

"BTO_SLAB",

pf.Rectangle((-5, 0), (-3, 10)),

)

_ = pf.tidy3d_plot(test_component, y=5)

\(V_\pi L\) Calculation¶

MZI Cross-Section¶

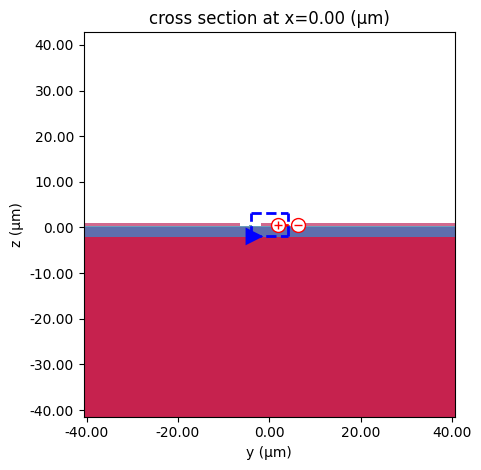

We calculate the vertical offset needed to place two optical waveguides symmetrically within the CPW gaps. These waveguides form the arms of a Mach-Zehnder Interferometer (MZI), where the electro-optic modulator induces a phase shift in the arms by applying an RF signal. Using the default technology port specifications, we create a composite MZI cross-section that combines the RF transmission line with the optical waveguides. We then visualize this configuration and overlay the voltage and current integration paths used in the impedance calculation.

[7]:

# Calculate the offset for placing waveguides in the middle of the CPW gaps

mzi_offset = signal_width / 2 + gap_width / 2

# Get the optical waveguide port specification ("RWG800")

wg_spec = pf.config.default_technology.ports["RWG800"]

# Get the RF CPW port specification ("UniCPW")

cpw_port = pf.config.default_technology.ports["UniCPW"]

# Create the combined MZI cross-section spec: CPW + two offset waveguides

mzi_spec_rf = cpw_port.combined_with(wg_spec, mzi_offset).combined_with(

wg_spec, -mzi_offset

)

# Create a Tidy3D impedance calculator instance based on the MZI cross-section

ic = mzi_spec_rf.to_tidy3d_impedance_calculator()

# Plot the MZI cross-section geometry

ax = pf.tidy3d_plot(mzi_spec_rf)

# Plot the voltage integration path on the cross-section

_ = ic.voltage_integral.plot(ax=ax, x=0)

# Plot the current integration path on the cross-section

_ = ic.current_integral.plot(ax=ax, x=0)

10:09:54 -03 WARNING: RF simulations and functionality will require new license requirements in an upcoming release. All RF-specific classes are now available within the sub-package 'tidy3d.rf'. - Contains a 'LossyMetalMedium'.

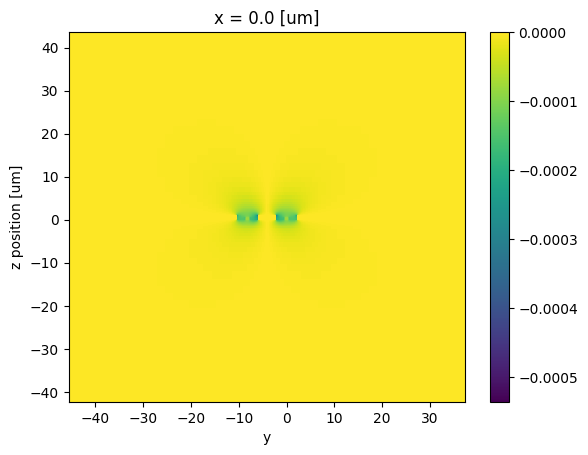

The Electro-Optic Response in the MZI Cross-Section¶

We simulate the RF mode in the composite CPW + MZI structure at 1 GHz. Using the computed field, we calculate the voltage using the defined integration path, then normalize the electric field component (Ey) by this voltage. This gives us the field distribution per unit volt, which we align with the optical waveguide center. Using the Pockels effect, we then compute the change in refractive index (Δn) within the BTO material due to the applied field. This refractive index change is responsible for inducing a phase shift in the MZI arm, enabling modulation.

[8]:

freq_rf = [1e9] # Frequency at which RF simulation is performed

# Calculate RF modes for the CPW line

mode_solver_rf, z0_rf = pf.port_modes(

mzi_spec_rf, freq_rf, mesh_refinement=50, impedance=True, group_index=True

)

# Calculate the voltage associated with the simulated RF mode using the defined integral path

v0 = ic.voltage_integral.compute_voltage(mode_solver_rf.data)

# Calculate the normalized Ey field (Ey per unit volt)

ey_norm = (mode_solver_rf.data.Ey / v0).isel(f=0, mode_index=0, drop=True).abs

# Shift y-coordinates to center relative to the optical waveguide position

ey_norm = ey_norm.assign_coords(y=ey_norm.y - mzi_offset)

n_e = 2.274 # Extraordinary refractive index for BTO

n_o = 2.312 # Ordinary refractive index for BTO

# Define the r33 electro-optic coefficient (µm/V)

r33 = 112e-6

# Calculate the change in refractive index (Δn) per unit volt using the Pockels effect

Δn = -0.5 * n_e**3 * r33 * ey_norm

# Plot the calculated Δn distribution in the cross-section (x=0)

_ = Δn.isel(x=0).transpose("z", "y").plot(robust=False)

Uploading task 'Mode-ModeSolver…'

Starting task 'Mode-ModeSolver': https://tidy3d.simulation.cloud/workbench?taskId=mo-713d0adc-924f-47af-b427-c6dd9baf055a

Downloading data from 'Mode-ModeSolver'…

Progress: 100%

Defining a Perturbed Optical Mode Solver¶

We now create a voltage-dependent optical solver to simulate the electro-optic modulation effect in BTO. The ordinary permittivity (used in the xx and zz directions) is assumed constant, while the extraordinary axis (yy) is perturbed according to the applied voltage and the Pockels-induced refractive index change (Δn). We use this modified anisotropic medium to compute the new optical modes, allowing us to evaluate the phase shift in the MZI arm under different voltage conditions.

[9]:

# Create a spatially uniform DataArray for the ordinary permittivity (used for xx, zz components)

eps_o_array = td.SpatialDataArray(

np.full((1, 1, 1), n_o**2), coords={"x": [0], "y": [0], "z": [0]}

)

# Define a function to run the optical mode solver with voltage-perturbed BTO

def perturbed_solver(voltage):

# Create a custom anisotropic medium definition for BTO including the EO effect

perturbed_bto = td.CustomAnisotropicMedium(

xx=td.CustomMedium(permittivity=eps_o_array, subpixel=True), # ordinary (x)

yy=td.CustomMedium(

permittivity=(n_e + voltage * Δn) ** 2, subpixel=True

), # EO perturbed (y)

zz=td.CustomMedium(permittivity=eps_o_array, subpixel=True), # ordinary (z)

)

# Run the mode solver for the waveguide spec at the optical frequency

# Use a custom technology where BTO is replaced by the perturbed version

return pf.port_modes(

wg_spec, [pf.C_0 / lambda_0], technology=custom_bto_pdk(bto=perturbed_bto)

)

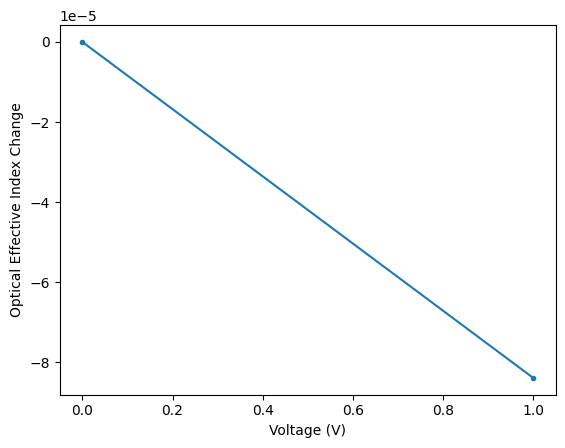

Extracting \(V_\pi L\)¶

We sweep the applied voltage across a specified range and compute the corresponding optical effective index (\(n_\mathrm{eff}\)) using the voltage-perturbed solver. By calculating the change in \(n_\mathrm{eff}\) per volt, we estimate the modulator’s \(V_\pi L\) figure of merit using the standard relation \(V_\pi L = \lambda_0 / (2 \, |dn_\mathrm{eff}/dV|)\). The result is reported for both single-drive and push-pull configurations.

[10]:

td.config.logging_level = "ERROR"

# Define the range of voltages for the sweep

voltages = np.arange(2)

# Calculate optical n_eff for each voltage using the perturbed_solver function

n_eff = [

perturbed_solver(v).data.n_eff.isel(mode_index=0, f=0).item() for v in voltages

]

# Plot optical effective index change vs applied voltage

delta_n_eff = np.array(n_eff) - n_eff[0]

_ = plt.plot(voltages, delta_n_eff, ".-")

plt.gca().set(xlabel="Voltage (V)", ylabel="Optical Effective Index Change")

plt.show()

# Calculate the change in n_eff per volt (dneff/dV) using the first and last points

dneff_dv = abs(n_eff[-1] - n_eff[0]) / (voltages[-1] - voltages[0])

# Calculate V_pi*L using the formula: Vπ·L = λ₀ / (2 * |dn_eff/dV|)

vpil = 0.5 * lambda_0 / dneff_dv # Result in V·μm

# Print Vπ·L in V·cm for single-drive configuration

print(f"Vπ·L (single-drive) = {vpil * 1e-4:.2f} V·cm")

# Print Vπ·L in V·cm for push-pull configuration (half of single-drive)

print(f"Vπ·L (push-pull) = {vpil * 1e-4 / 2:.2f} V·cm")

Uploading task 'Mode-ModeSolver…'

Starting task 'Mode-ModeSolver': https://tidy3d.simulation.cloud/workbench?taskId=mo-2c29ba2a-8cff-478b-90e8-79706ff2317f

Downloading data from 'Mode-ModeSolver'…

Progress: 100%

Uploading task 'Mode-ModeSolver…'Progress: 0% -

Starting task 'Mode-ModeSolver': https://tidy3d.simulation.cloud/workbench?taskId=mo-f094d324-7874-42e8-96e1-4bbf8d90417a

Downloading data from 'Mode-ModeSolver'…

Progress: 100%

Vπ·L (single-drive) = 0.91 V·cm

Vπ·L (push-pull) = 0.45 V·cm