Differential Coplanar Waveguide¶

In this notebook, we simulate and analyze a differential coplanar waveguide (CPW) structure using both mode solving and time-domain FDTD methods within PhotonForge.

Our goal is to extract key transmission line properties—impedance, effective index, and loss—for a differential pair over a wide frequency range. We benchmark the results against a reference simulation from another commercial software to validate accuracy.

We start by defining the physical dimensions and material parameters of the CPW layout. All values are selected to match a reference example. The impedance results are compared across varying signal-to-signal spacings to demonstrate consistency with expected differential behavior.

Later in the notebook, we simulate a 1 cm differential CPW line using both FDTD and a Waveguide-based model, and compare their scattering parameters to verify agreement.

[1]:

import numpy as np

import photonforge as pf

import tidy3d as td

from matplotlib import pyplot as plt

from tidy3d.plugins.dispersion import FastDispersionFitter

td.config.logging_level = "ERROR"

pf.config.default_mesh_refinement = 30 # Set default mesh refinement

Parameters for Differential CPW Geometry¶

In this section, we define the physical and electrical parameters of the differential coplanar waveguide (CPW) structure based on the diagram provided above. We set the conductor and substrate properties, geometry dimensions, and simulation frequency range. The units are converted using the mil factor (1 mil = 25.4 microns), which is commonly used in PCB and microwave engineering.

[2]:

f_min = 1e9 # minimum frequency (Hz)

f_max = 50e9 # maximum frequency (Hz)

mil = 25.4 # conversion factor: 1 mil = 25.4 microns

losstan_sub = 0.015 # substrate loss tangent

cond_metal = 41 # metal conductivity

eps_sub = 4.2 # relative permittivity of substrate

h = 8.5 * mil # substrate thickness

w1 = 7 * mil # signal width (bottom)

w2 = 6 * mil # signal width (top)

s = 2 * mil # spacing between signal lines

g1 = 101 * mil # ground width (bottom)

g2 = 100 * mil # ground width (top)

d = 8 * mil # gap between signal and ground

t = 1.2 * mil # conductor thickness

freqs = np.linspace(f_min, f_max, 21) # frequency sweep points

Simple PCB Technology¶

We define a reusable Technology class that represents a simple PCB stack for our differential CPW. This includes the substrate and transmission line (TL) metal layers. The function allows us to customize key physical properties such as conductor thickness, substrate thickness, and sidewall angle. The stack-up also specifies materials used for the substrate, metal, and surrounding dielectric opening. This technology will be passed to layout and simulation components later.

[3]:

_Medium = td.components.medium.MediumType # type alias for medium input

def basic_pcb_tech(

*,

sidewall_angle: float = 22.6, # sidewall taper angle (deg)

sub_thickness: float = 8.5 * mil, # substrate thickness (microns)

tl_thickness: float = 1.2 * mil, # conductor thickness (microns)

substrate: _Medium = td.Medium(

permittivity=4.2, name="Substrate"

), # substrate material

tl_metal: _Medium = td.PECMedium(), # metal for transmission lines

opening: _Medium = td.Medium(

permittivity=1.0, name="Opening"

), # surrounding dielectric

) -> pf.Technology:

# Layers

layers = {

"TL": pf.LayerSpec(

layer=(21, 0), # GDS layer for metal

description="Metal transmission lines",

color="#eadb0718",

pattern="\\",

),

}

# Extrusion specifications

bounds = pf.MaskSpec() # empty mask for entire domain

tl_mask = pf.MaskSpec((21, 0)) # mask for transmission lines

extrusion_specs = [

pf.ExtrusionSpec(bounds, substrate, (-sub_thickness, 0)), # extrude substrate

pf.ExtrusionSpec(

tl_mask, tl_metal, (0, tl_thickness), sidewall_angle

), # extrude TLs

]

# Create and return PCB technology stack

technology = pf.Technology("PCB", "0", layers, extrusion_specs, {}, opening)

return technology

We compute the effective sidewall angle based on the difference between ground and signal widths, assuming symmetric metal tapering. This angle is then used to instantiate our PCB technology stack. Finally, we set this technology as the default in PhotonForge for use in subsequent component definitions and simulations.

[4]:

# compute metal sidewall angle in degrees

sidewall_angle = np.degrees(np.arctan((w1 - w2) / 2 / t))

# instantiate PCB tech

tech = basic_pcb_tech(sidewall_angle=sidewall_angle, sub_thickness=h)

pf.config.default_technology = tech # set as default technology

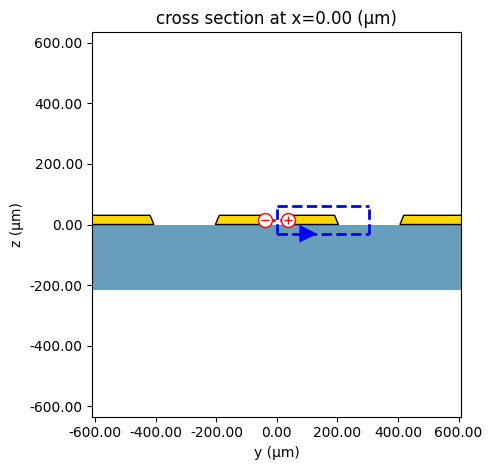

Port Definition¶

We define a PortSpec object for the differential CPW using the smallest signal spacing value. This specification includes metal trace profiles as well as paths used to compute voltage and current integrals for impedance extraction.

To better understand the setup, we visualize the port cross-section at the simulation center and overlay the voltage and current integration paths. This helps confirm that the field sampling and excitation definitions are aligned with the geometry and symmetry of the structure.

[5]:

dcpw_spec = pf.PortSpec(

description="Differential CPW transmission line",

width=2 * g1 + s + 2 * w1 + 2 * d - 1 * mil, # simulation domain width

limits=(-100 * mil, 100 * mil), # z-axis extent

num_modes=1, # number of target modes

added_solver_modes=0, # extra solver modes

polarization="", # default polarization

target_neff=2, # expected effective index

path_profiles={ # cross-sectional layout

"gnd0": (g2, w1 + d + (s + g1) / 2, (21, 0)),

"gnd1": (g2, -(w1 + d + (s + g1) / 2), (21, 0)),

"signal0": (w2, -(s + w1) / 2, (21, 0)),

"signal1": (w2, (s + w1) / 2, (21, 0)),

},

voltage_path=[ # voltage integration line

(-s / 2 - (w1 - w2) / 2, t / 2),

(s / 2 + (w1 - w2) / 2, t / 2),

],

current_path=[ # current integration loop

(w1 + s / 2 + d / 2, 2 * t),

(0, 2 * t),

(0, -t),

(w1 + s / 2 + d / 2, -t),

],

)

ax = pf.tidy3d_plot(dcpw_spec, frequency=freqs[0]) # plot port geometry

ic = dcpw_spec.to_tidy3d_impedance_calculator() # create impedance calculator

_ = ic.voltage_integral.plot(ax=ax, x=0) # overlay voltage path

_ = ic.current_integral.plot(ax=ax, x=0) # overlay current loop

ax.set_xlim((-(s / 2 + w1 + 2 * d), (s / 2 + w1 + 2 * d))) # limit x view

ax.set_ylim((-25 * mil, 25 * mil)) # limit y view

plt.show()

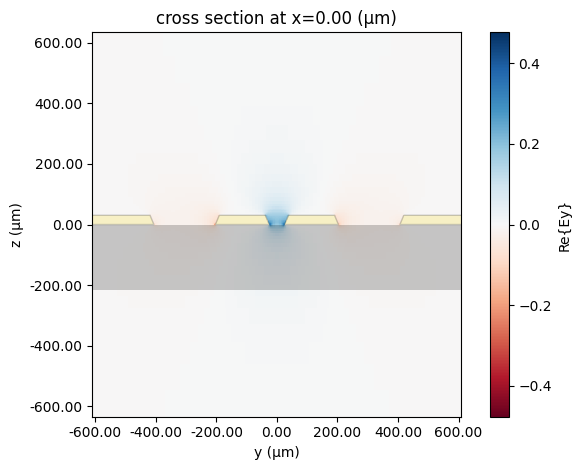

Inspect Ey Field to Verify Differential Mode¶

To extract the correct differential impedance, we first visualize the electric field distribution for the computed mode. We verify the odd-symmetry voltage mode (i.e., the differential mode) by inspecting the Ey component of the fields.

We apply mirror symmetry to the simulation domain to ensure that the computed field profiles respect the physical symmetry of the differential structure. This not only reduces simulation size but also significantly improves the accuracy of impedance extraction.

[6]:

cpw_solver = dcpw_spec.to_tidy3d(freqs) # solve for port modes

cpw_solver_sym = cpw_solver.updated_copy(

simulation=cpw_solver.simulation.updated_copy(

symmetry=(0, -1, 0), # apply y-symmetry

)

)

mode_data = pf.port_modes(cpw_solver_sym) # extract mode field data

ax = mode_data.plot_field("Ey", "real", f=freqs[0], robust=False)

ax.set_xlim((-(s / 2 + w1 + 2 * d), (s / 2 + w1 + 2 * d))) # x-range

ax.set_ylim((-25 * mil, 25 * mil)) # y-range

plt.show()

Starting…

10:09:42 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-e7b584a1-58e2- 4f63-94ef-acef78e2255f'.

Progress: 100%

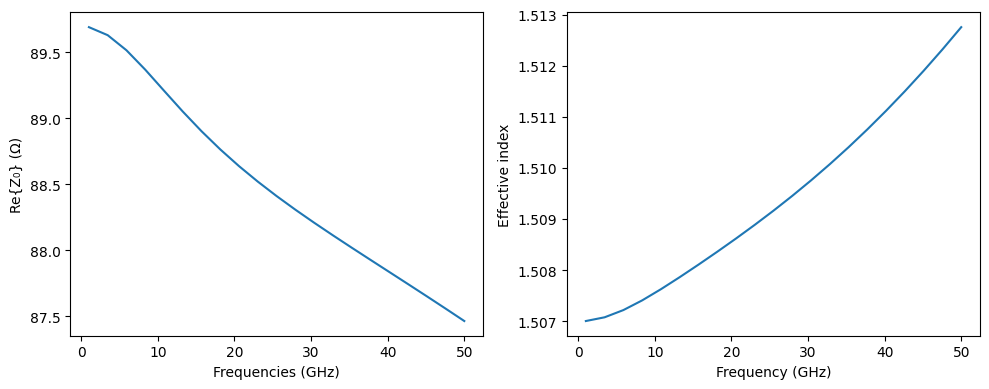

Extract Impedance and Effective Index¶

After computing the differential mode, we extract its physical characteristics across the frequency range. These include:

The real part of the differential impedance

Z₀,The effective refractive index

n_eff, and

[7]:

# differential impedance

z0 = ic.compute_impedance(mode_data.data).real

n_eff = mode_data.data.n_eff # effective index

fig, ax = plt.subplots(1, 2, figsize=(10, 4), tight_layout=True)

ax[0].plot(z0.f * 1e-9, z0) # plot impedance vs frequency

ax[0].set(xlabel="Frequencies (GHz)", ylabel="Re{Z₀} (Ω)")

ax[1].plot(freqs / 1e9, n_eff) # plot effective index

ax[1].set_xlabel("Frequency (GHz)")

ax[1].set_ylabel("Effective index")

plt.show()

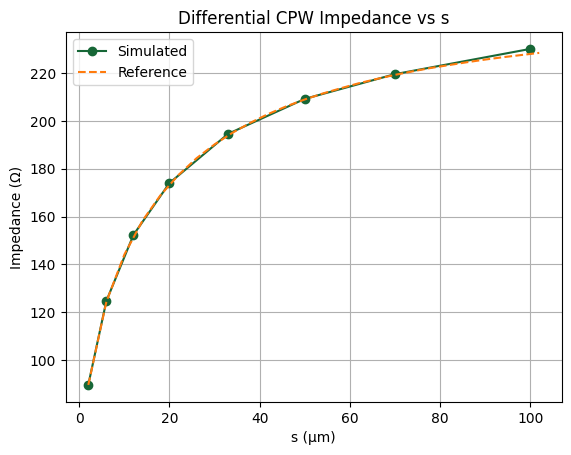

Benchmark Simulated Impedance Against Reference Data¶

In this section, we verify the simulated differential impedance of the CPW structure by comparing it with a reference simulation from another commercial software. We sweep the signal-to-ground spacing s and extract the real part of the differential impedance at the fundamental mode.

Here, we present an alternative approach for computing the impedance without enforcing symmetry directly in the simulation setup. In this case, small numerical asymmetries in the computed field profiles can cause slight differences in the calculated currents on the two signal traces. To account for this, we compute the impedance twice—once for each current path mirrored across the centerline—and then combine the results by summing their reciprocals. This method aligns with the definition of

differential impedance, which is inversely proportional to the total current. The second call to pf.port_modes reuses the cached field solution and only recalculates the impedance, adding negligible overhead to the total simulation time.

It’s also important to note that the differential impedance Z₀(diff) is equal to twice the odd-mode impedance Z₀(odd) of a single-ended structure. As the spacing s increases, coupling between the signal lines decreases, and Z₀(diff) asymptotically approaches twice the single-ended value. In our case, the impedance saturates around 228 Ω, which aligns well with the expected 112 Ω of an isolated single-ended CPW line with the same geometry.

[8]:

s_values = np.array([2, 6, 12, 20, 33, 50, 70, 100]) * mil # sweep values for gap s

z0_real_values = [] # store real parts of simulated impedance

for s in s_values:

spec = pf.PortSpec(

description="Differential CPW transmission line",

width=2 * g1 + s + 2 * w1 + 2 * d - 1 * mil, # simulation domain width

limits=(-100 * mil, 100 * mil), # z-axis extent

num_modes=1, # number of target modes

added_solver_modes=0, # extra solver modes

polarization="", # default polarization

target_neff=2, # expected effective index

path_profiles={ # cross-sectional layout

"gnd0": (g2, w1 + d + (s + g1) / 2, (21, 0)),

"gnd1": (g2, -(w1 + d + (s + g1) / 2), (21, 0)),

"signal0": (w2, -(s + w1) / 2, (21, 0)),

"signal1": (w2, (s + w1) / 2, (21, 0)),

},

voltage_path=[ # differential voltage path

(-s / 2 - (w1 - w2) / 2, t / 2),

(s / 2 + (w1 - w2) / 2, t / 2),

],

current_path=[ # differential current loop

(w1 + s / 2 + d / 2, 2 * t),

(0, 2 * t),

(0, -t),

(w1 + s / 2 + d / 2, -t),

],

)

_, z0_1 = pf.port_modes(spec, [freqs[0]], impedance=True)

spec.current_path = [(-x, y) for x, y in spec.current_path]

_, z0_2 = pf.port_modes(spec, [freqs[0]], impedance=True)

z0 = 2 / (1 / z0_1 + 1 / z0_2)

z0_real_values.append(z0.isel(f=0).real.item())

# Reference data from another commercial simulation

data_ref = [

[2, 89.5],

[6, 124.3],

[10, 144.1],

[14, 158.2],

[18, 168.9],

[22, 177.4],

[26, 184.4],

[30, 190.2],

[34, 195.1],

[38, 199.3],

[42, 203.0],

[46, 206.2],

[50, 209.0],

[54, 211.5],

[58, 213.7],

[62, 215.8],

[66, 217.6],

[70, 219.3],

[74, 220.8],

[78, 222.2],

[82, 223.4],

[86, 224.6],

[90, 225.7],

[94, 226.7],

[98, 227.6],

[102, 228.5],

]

s_ref = [row[0] for row in data_ref] # reference s values

z0_ref = [row[1] for row in data_ref] # reference impedance values

# Plot both

plt.figure()

plt.plot(

s_values / mil, z0_real_values, marker="o", label="Simulated"

) # simulation results

plt.plot(s_ref, z0_ref, linestyle="--", label="Reference") # reference curve

plt.xlabel("s (µm)")

plt.ylabel("Impedance (Ω)")

plt.title("Differential CPW Impedance vs s")

plt.legend()

plt.grid(True)

plt.show()

# Reset s to default vaule

s = 2 * mil

Starting…

10:09:43 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-0f05138d-c407- 4bcf-8a7d-6ba475212232'.

Progress: 100%

Progress: 100%

Starting…

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-e55afab6-d229- 4c15-a772-68e0befb7a7a'.

Progress: 100%

Progress: 100%

Starting…

10:09:44 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-cca768d3-83b1- 4e90-8b51-4cc1edd42ca7'.

Progress: 100%

Progress: 100%

Starting…

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-ed9d2bde-8e99- 4560-a1e6-2c9ba74b7cc3'.

Progress: 100%

Progress: 100%

Starting…

10:09:45 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-e39c3974-87be- 4336-b8ee-5027192613ee'.

Progress: 100%

Progress: 100%

Starting…

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-8476688a-a3e1- 475f-b514-115985765662'.

Progress: 100%

Progress: 100%

Starting…

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-89f50d46-b267- 47a7-8dcc-f475c90e9969'.

Progress: 100%

Progress: 100%

Starting…

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-3e8c0a5d-9125- 4855-bafc-35ec731dc4aa'.

Progress: 100%

Progress: 100%

Lossy Differential CPW¶

In this section, we aim to simulate a lossy differential CPW transmission line by defining frequency-dependent models for both the conductor and the substrate. This allows us to capture realistic attenuation behavior due to dielectric and conductor losses.

We use a surface impedance fitting model for the metal, and a constant-loss-tangent dispersion model for the substrate. These models are valid over the frequency range of interest and will be used in both FDTD and mode solver simulations. Later, we will compare the results of these two approaches to assess consistency and accuracy.

[9]:

lossy_metal: _Medium = td.LossyMetalMedium(

conductivity=cond_metal, # metal conductivity

frequency_range=[f_min, f_max], # fit range for frequency-dependent loss

fit_param=td.SurfaceImpedanceFitterParam(max_num_poles=16), # fitting parameters

)

lossy_substrate: _Medium = FastDispersionFitter.constant_loss_tangent_model(

eps_real=eps_sub, # real permittivity of substrate

loss_tangent=losstan_sub, # loss tangent for lossy dielectric

frequency_range=(f_min, f_max), # frequency range of interest

)

tech = basic_pcb_tech(

sidewall_angle=sidewall_angle, # sidewall taper angle

sub_thickness=h, # substrate thickness

substrate=lossy_substrate, # frequency-dependent substrate model

tl_metal=lossy_metal, # frequency-dependent metal model

)

pf.config.default_technology = tech # set lossy tech as default

FDTD Simulation¶

We now simulate a 1 cm long differential CPW line using FDTD to evaluate its broadband S-parameter response. A field monitor is placed at the center of the line to record cross-sectional fields, which will later be used for mode inspection.

The structure is configured using the same port specification as the mode solver, and we apply mirror symmetry. After activating the model, we extract the full scattering matrix over the desired frequency range.

[10]:

dcpw_length = 10000 # 1 cm line length in microns

field_monitor_yz = td.FieldMonitor(

center=(dcpw_length / 2, 0, 0), # center of the transmission line

size=(0, td.inf, td.inf), # yz cross-section

freqs=[20e9], # monitor frequency

name="field_yz", # monitor name

)

dcpw_line = pf.parametric.straight( # create straight DCPW line

port_spec=dcpw_spec,

length=dcpw_length,

name="DCPW Line",

model=pf.Tidy3DModel(

port_symmetries=[("E1", "E0")],

symmetry=(0, -1, 0), # apply symmetry

monitors=[field_monitor_yz], # add field monitor

),

)

dcpw_line.activate_model("Tidy3D") # activate FDTD model

s_matrix = dcpw_line.s_matrix(frequencies=freqs) # simulate and extract S-parameters

# pf.tidy3d_plot(dcpw_line, z=t / 2, hlim=(-500, 10100), vlim=(-2000, 2000))

pf.tidy3d_plot(dcpw_line, plot_type="3d")

Uploading task 'E0@0…'

10:09:51 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-4f5bcecb-51c8- 4c4b-a2b7-afee36aa211d'.

Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-8fd0a6a8-b8aa- 4005-8aba-94e919a47e3c'.

Starting task 'E0@0': https://tidy3d.simulation.cloud/workbench?taskId=fdve-e06527f8-8aab-444c-b404-01c2f787773d

Downloading data from 'E0@0'…

Progress: 100%

Simulate S-Matrix Using Waveguide Model¶

We now switch from full-wave FDTD simulation to the Waveguide model, which reconstructs the transmission behavior using modal propagation constants such as effective index and loss. This model provides an efficient alternative for long uniform structures.

By activating the Waveguide model for our 1 cm differential CPW line, we compute the corresponding S-matrix across the frequency sweep. The result can be directly compared to the FDTD simulation for validation.

[11]:

# Replace with a Waveguide model

dcpw_line.update(model=pf.WaveguideModel())

# simulate and extract S-parameters

s_matrix_mode = dcpw_line.s_matrix(frequencies=freqs)

Starting…

10:10:04 -03 Loading simulation from local cache. View cached task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-8f79e7b8-4e72- 4bf1-82b4-e02904905961'.

Progress: 100%

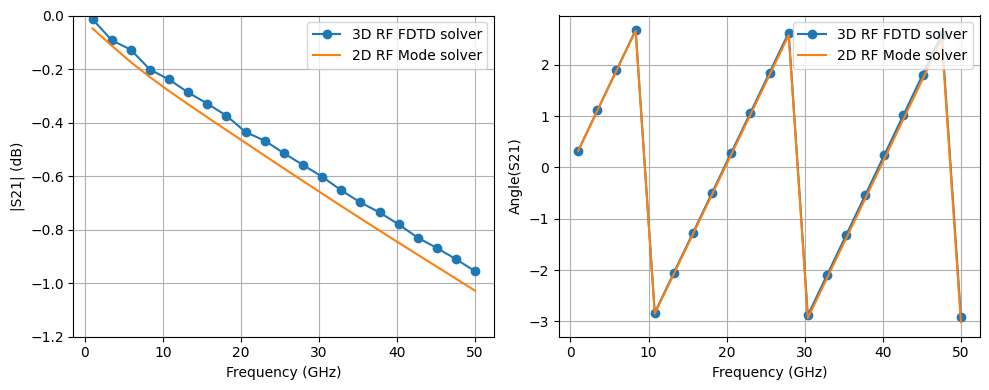

Compare 3D FDTD RF Model and Waveguide Model¶

We finalize the comparison by plotting the transmission response of the differential CPW line obtained from both our GPU-accelerated RF FDTD solver and the Waveguide model (RF mode solver).

We plot the magnitude and phase of S21 for both approaches. Good agreement confirms the validity of using the Waveguide model as an efficient surrogate for full-wave simulations when the geometry is uniform and dispersion is captured accurately.

[12]:

# Extract S-parameters

s21 = s_matrix["E0@0", "E1@0"] # FDTD result

s21_mode = s_matrix_mode["E0@0", "E1@0"] # Waveguide model result

# Create subplots

fig, ax = plt.subplots(1, 2, figsize=(10, 4), sharex=True)

# Plot |S21| in dB

ax[0].plot(

freqs / 1e9, 20 * np.log10(np.abs(s21)), marker="o", label="3D RF FDTD solver"

)

ax[0].plot(freqs / 1e9, 20 * np.log10(np.abs(s21_mode)), label="2D RF Mode solver")

ax[0].set_xlabel("Frequency (GHz)")

ax[0].set_ylabel("|S21| (dB)")

ax[0].set_ylim((-1.2, 0))

ax[0].grid(True)

ax[0].legend()

# Plot phase of S21

ax[1].plot(freqs / 1e9, np.angle(s21), marker="o", label="3D RF FDTD solver")

ax[1].plot(freqs / 1e9, np.angle(s21_mode), label="2D RF Mode solver")

ax[1].set_xlabel("Frequency (GHz)")

ax[1].set_ylabel("Angle(S21)")

ax[1].grid(True)

ax[1].legend()

plt.tight_layout()

plt.show()

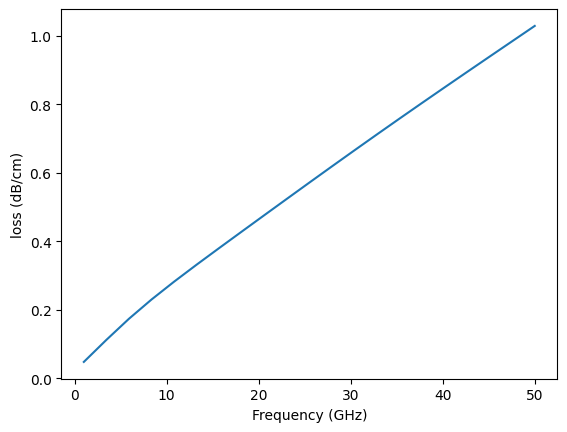

We could also directly use the port_modes data to extract loss.

[13]:

mode_data = pf.port_modes(dcpw_spec, freqs)

# loss in dB/cm

alpha = mode_data.data.modes_info["loss (dB/cm)"]

plt.plot(freqs / 1e9, alpha) # plot loss in dB/cm

plt.xlabel("Frequency (GHz)")

plt.ylabel("loss (dB/cm)")

plt.show()

Progress: 100%