Fiber Ports¶

Ports are the used in PhotonForge to represent connections that use waveguides constructed from a technology’s layers and extrusion profiles. Fiber ports are used to create similar connections via waveguides outside the technology’s specifications, such as an optical fiber, which is the most common use of this class, hence its name.

This type of port is specified in 3D space by a position and an input vector, similarly to a Gaussian port. It also requires the specification of it cross-sectional geometry from planar structures and the media they represent. These structures have no representation in the component layout, so they are not exported to GDSII or OASIS files, for example.

[1]:

import photonforge as pf

import tidy3d as td

import numpy as np

tech = pf.basic_technology()

pf.config.default_technology = tech

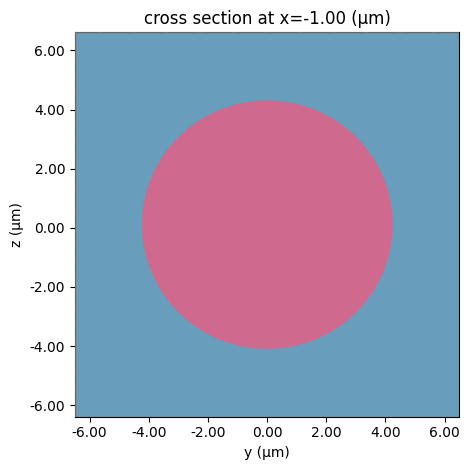

Port Cross-Section¶

The cross-section of a fiber port is described by a list of planar structures and the media associated to them once the cross-section is extruded into a 3D waveguide. As a simple example, we can create a conventional single-mode optical fiber as follows. Note that the port size is considerably smaller than the full fiber cladding region, because it is only large enough to support the mode confined in the core region. Furthermore, the core is sligthly non-circular to help with the LP mode orientations.

[2]:

fiber_port = pf.FiberPort(

center=(-1, 0, 0.11),

input_vector=(1, 0, 0),

size=(13, 13),

extrusion_limits=(-100, 1),

cross_section=[

(pf.Circle(62.5), td.Medium(permittivity=1.445**2)),

(pf.Circle((4.24, 4.2)), td.Medium(permittivity=1.46**2)),

],

num_modes=1,

target_neff=1.46,

)

_ = pf.tidy3d_plot(fiber_port)

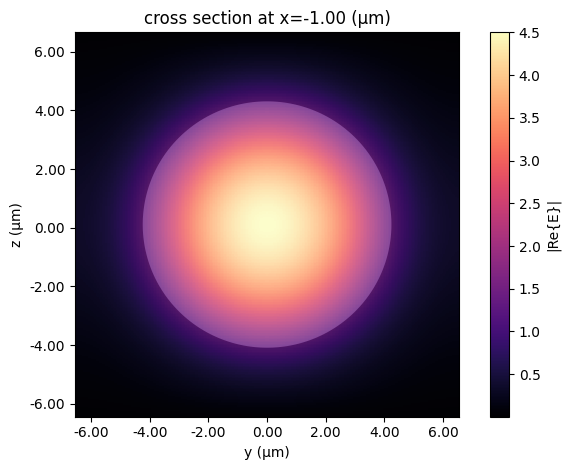

Similarly to Port instances, we can export a mode solver to inspect the fiber port’s modes or compute the modes directly with the port_modes function.

[3]:

freqs = [pf.C_0 / 1.55]

mode_solver = pf.port_modes(fiber_port, freqs)

mode_solver.plot_field("E", mode_index=0, f=freqs[0], robust=False)

mode_solver.data.to_dataframe()

Uploading task 'Mode-ModeSolver…'Progress: 0% -

Starting task 'Mode-ModeSolver': https://tidy3d.simulation.cloud/workbench?taskId=mo-5b9a4872-884d-4705-b6c8-cf6a1974efed

Downloading data from 'Mode-ModeSolver'…

Progress: 100%

[3]:

| wavelength | n eff | k eff | TE (Ey) fraction | wg TE fraction | wg TM fraction | mode area | ||

|---|---|---|---|---|---|---|---|---|

| f | mode_index | |||||||

| 1.934145e+14 | 0 | 1.55 | 1.455943 | 0.0 | 0.999998 | 0.998012 | 0.997799 | 47.043027 |

The fiber cross-section is always centered around the origin. The origin is placed at the port’s center normal to its input vector, which is the extrusion direction of the waveguide. The extrusion extends behind and in front of the cross-section plane according to the extrusion_limits.

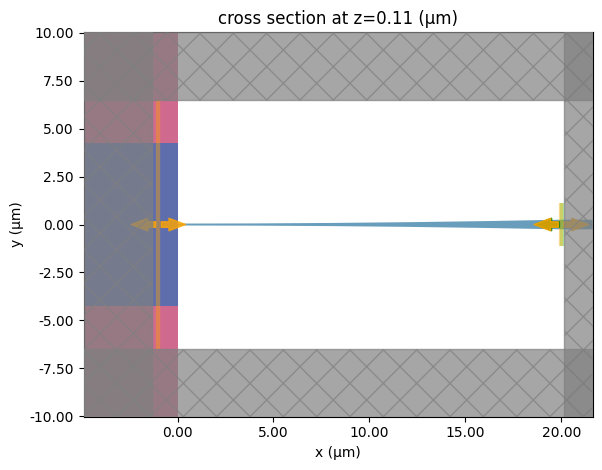

We can show that by adding the port to a component, in this case, an inverse taper with parabolic profile. First we see that the component layout does not include any geometry from the fiber port:

[4]:

taper_length = 20

taper_tip = 0.1

taper_width = pf.Expression(

"u",

[

("w0", taper_tip),

("dw", 0.5 - taper_tip),

("width", "w0 + dw * u^2"),

("derivative", "dw * 2 * u"),

],

)

taper = pf.Component("TAPER")

# Taper geometry

taper.add(

"WG_CORE",

pf.Path((0, 0), taper_tip)

.segment((taper_length, 0), taper_width),

"WG_CLAD",

pf.stencil.linear_taper(widths=(9, 3), length=taper_length),

)

# Ports

taper.add_port(pf.Port((taper_length, 0), 180, "Strip"), "P0")

taper.add_port(fiber_port, "P1")

taper

[4]:

With the tidy3d_plot utility we can quickly inspect the extruded geometry and see the fiber port in full:

[5]:

_ = pf.tidy3d_plot(taper, z=0.11)

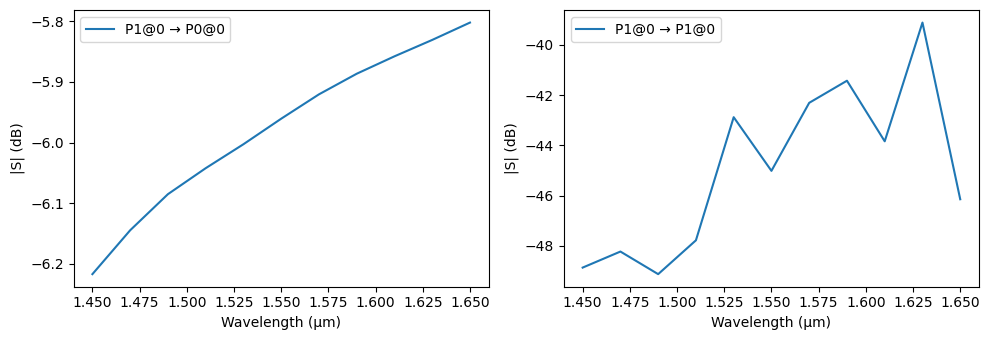

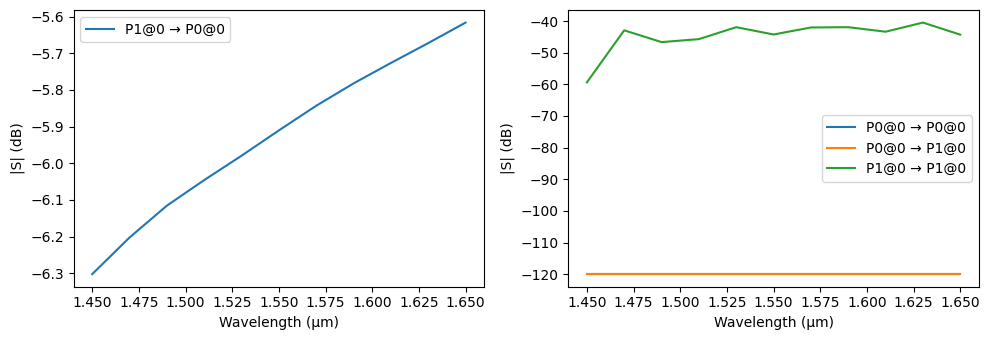

We can evaluate the coupling by computing the component’s S parameters with a Tidy3D model. Note the use of symmetry to force the correct fiber mode from the degenerate pair of LP fiber modes.

[6]:

taper.add_model(pf.Tidy3DModel(symmetry=(0, -1, 0)), "Tidy3D")

s = taper.s_matrix(pf.C_0 / np.linspace(1.45, 1.65, 11), model_kwargs={"inputs": ["P1"]})

_ = pf.plot_s_matrix(s, y="dB")

Uploading task 'P1@0…'

Uploading task 'P0…'

Uploading task 'P1…'

Starting task 'P1@0': https://tidy3d.simulation.cloud/workbench?taskId=fdve-fd348997-8c6a-41c3-8558-1731498cd6d6

Starting task 'P0': https://tidy3d.simulation.cloud/workbench?taskId=mo-fc0edea6-c2f4-443a-9a8a-12f793c7c29b

Starting task 'P1': https://tidy3d.simulation.cloud/workbench?taskId=mo-69f084ea-96eb-46bd-8b0e-dea7ac97dfc7

Downloading data from 'P0'…

Downloading data from 'P1'…

Downloading data from 'P1@0'…

Progress: 100%

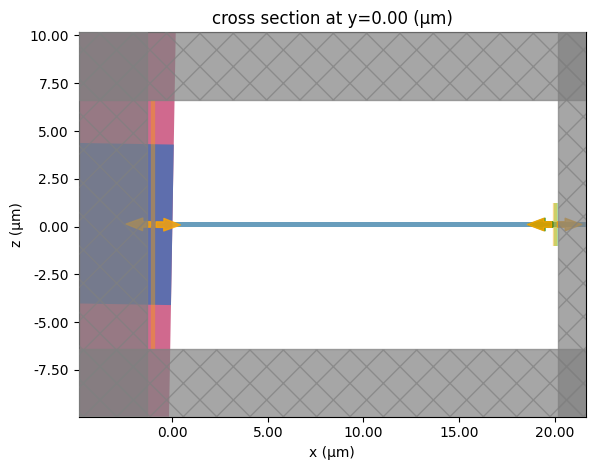

As an example of simple analysis, we can check the effect in the coupling once the fiber is tilted by 2° downwards (lateral rotations have to be accompanied by a removal of the symmetry plane). The mode solver will find non-physical modes when the angle is included, so we add another mode to it, to make sure we find the correct one.

[7]:

angle = -1 * np.pi / 180.0

fiber_port.input_vector = (np.cos(angle), 0, np.sin(angle))

fiber_port.num_modes = 2

_ = pf.tidy3d_plot(taper, y=0)

[8]:

s = taper.s_matrix(pf.C_0 / np.linspace(1.45, 1.65, 11), model_kwargs={"inputs": ["P1"]})

_ = pf.plot_s_matrix(s, y="dB", input_ports=["P1"])

Uploading task 'P1@0…'

Uploading task 'P1@1…'

Uploading task 'P0…'

Uploading task 'P1…'

Starting task 'P1@0': https://tidy3d.simulation.cloud/workbench?taskId=fdve-05e1d24b-d542-41b7-a9d2-3e7a02d09c39

Starting task 'P0': https://tidy3d.simulation.cloud/workbench?taskId=mo-ecc75f20-312f-4258-b9fa-b69a167faa31

Starting task 'P1@1': https://tidy3d.simulation.cloud/workbench?taskId=fdve-4bced6df-d767-4f1d-8b19-9c8c2f0700c0

Starting task 'P1': https://tidy3d.simulation.cloud/workbench?taskId=mo-d9a96478-9c7c-4f33-b7b0-e3a6374772e8

Downloading data from 'P0'…

Downloading data from 'P1'…

Downloading data from 'P1@1'…

Downloading data from 'P1@0'…

Progress: 100%