Adjoint-based shape optimization of a waveguide bend#

In this notebook, we will apply the adjoint method to the optimization of a low-loss waveguide bend. We start with a 90 degree bend in a SiN waveguide, parameterized using a td.PolySlab.

We define an objective function that seeks to maximize the transmission of the TE0 output mode amplitude with respect to the position of the polygon vertices defining the bend. A penalty is applied to keep the local radii of curvature larger than a predefined value.

The resulting device demonstrates low loss and exhibits a smooth geometry.

To install the

autogradpackage required for this feature, we recommend runningpip install autograd.

If you are unfamiliar with inverse design, we also recommend our intro to inverse design tutorials and our primer on automatic differentiation with tidy3d.

Setup#

First, we import tidy3d. We will also use numpy, matplotlib and autograd.

[1]:

import autograd as ag

import autograd.numpy as anp

import matplotlib.pylab as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

Next, we define all the global parameters for our device and optimization.

[2]:

wavelength = 1.5

freq0 = td.C_0 / wavelength

# frequency of measurement and source

# note: we only optimize results at the central frequency for now.

fwidth = freq0 / 10

num_freqs = 1

freqs = np.linspace(freq0 - fwidth / 2, freq0 + fwidth / 2, num_freqs)

freqs = np.array([freq0])

# define the discretization of the bend polygon in angle

num_pts = 60

angles = np.linspace(0, np.pi / 2, num_pts + 2)[1:-1]

# refractive indices of waveguide and substrate (air above)

n_wg = 2.0

n_sub = 1.5

# min space between waveguide and PML

spc = 1 * wavelength

# length of input and output straight waveguide sections

t = 1 * wavelength

# distance between PML and the mode source / mode monitor

mode_spc = t / 2.0

# height of waveguide core

h = 0.7

# minimum, starting, and maximum allowed thicknesses for the bend geometry

wmin = 0.5

wmid = 1.5

wmax = 2.5

# average radius of curvature of the bend

radius = 6

# minimum allowed radius of curvature of the polygon

min_radius = 150e-3

# name of the monitor measuring the transmission amplitudes for optimization

monitor_name = "mode"

# how many grid points per wavelength in the waveguide core material

min_steps_per_wvl = 20

# how many mode outputs to measure

num_modes = 3

mode_spec = td.ModeSpec(num_modes=num_modes)

Using all of these parameters, we can define the total simulation size.

[3]:

Lx = Ly = t + radius + abs(wmax - wmid) + spc

Lz = spc + h + spc

Define parameterization#

Next we describe how the geometry looks as a function of our design parameters.

At each angle on our bend discretization, we define a parameter that can range between -inf and +inf to control the thickness of that section. If that parameter is -inf, 0, and +inf, the thickness of that section is wmin, wmid, and wmax, respectively.

This gives us a smooth way to constrain our measurable parameter without needing to worry about it in the optimization.

[4]:

def thickness(param: float) -> float:

"""thickness of a bend section as a function of a parameter in (-inf, +inf)."""

param_01 = (anp.tanh(param) + 1.0) / 2.0

return wmax * param_01 + wmin * (1 - param_01)

Next we write a function to generate all of our bend polygon vertices given our array of design parameters. Note that we add extra vertices at the beginning and end of the bend that are independent of the parameters (static) and are only there to make it easier to connect the bend to the input and output waveguide sections.

[5]:

def make_vertices(params: np.ndarray) -> list:

"""Make bend polygon vertices as a function of design parameters."""

vertices = []

vertices.append((-Lx / 2 + 1e-2, -Ly / 2 + t + radius))

vertices.append((-Lx / 2 + t, -Ly / 2 + t + radius + wmid / 2))

for angle, param in zip(angles, params):

thickness_i = thickness(param)

radius_i = radius + thickness_i / 2.0

x = radius_i * np.sin(angle) - Lx / 2 + t

y = radius_i * np.cos(angle) - Ly / 2 + t

vertices.append((x, y))

vertices.append((-Lx / 2 + t + radius + wmid / 2, -Ly / 2 + t))

vertices.append((-Lx / 2 + t + radius, -Ly / 2 + 1e-2))

vertices.append((-Lx / 2 + t + radius - wmid / 2, -Ly / 2 + t))

for angle, param in zip(angles[::-1], params[::-1]):

thickness_i = thickness(param)

radius_i = radius - thickness_i / 2.0

x = radius_i * np.sin(angle) - Lx / 2 + t

y = radius_i * np.cos(angle) - Ly / 2 + t

vertices.append((x, y))

vertices.append((-Lx / 2 + t, -Ly / 2 + t + radius - wmid / 2))

return vertices

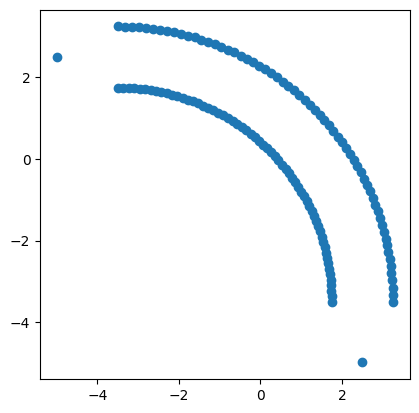

Let’s try out our make_vertices function on a set of all 0 parameters, which should give the starting waveguide width of wmid across the bend.

[6]:

params = np.zeros(num_pts)

vertices = make_vertices(params)

[7]:

plt.scatter(*np.array(vertices).T)

ax = plt.gca()

ax.set_aspect("equal")

Looks good, note again that the extra points on the ends are just to ensure a solid overlap with the in and out waveguides. At this time, the autograd differentiation does not handle polygons that extend outside of the simulation domain so we need to also ensure that all points are inside of the domain.

[8]:

def make_polyslab(params: np.ndarray) -> td.PolySlab:

"""Make a `tidy3d.PolySlab` for the bend given the design parameters."""

vertices = make_vertices(params)

return td.PolySlab(vertices=vertices, slab_bounds=(-h / 2, h / 2), axis=2)

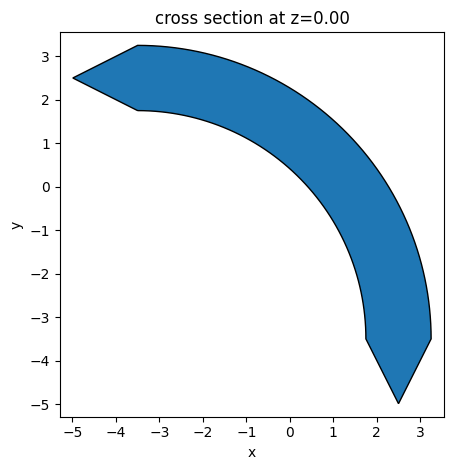

Let’s visualize this as well.

[9]:

polyslab = make_polyslab(params)

ax = polyslab.plot(z=0)

Keeping with this theme, we add a function to generate the structure itself.

[10]:

def make_structure(params) -> td.Structure:

polyslab = make_polyslab(params)

medium = td.Medium(permittivity=n_wg**2)

return td.Structure(geometry=polyslab, medium=medium)

[11]:

ring = make_structure(params)

ax = ring.plot(z=0)

Next, we define the other geometries, such as the input waveguide section, output waveguide section, and substrate.

[12]:

box_in = td.Box.from_bounds(

rmin=(-Lx / 2 - 1, -Ly / 2 + t + radius - wmid / 2, -h / 2),

rmax=(-Lx / 2 + t + 1e-3, -Ly / 2 + t + radius + wmid / 2, +h / 2),

)

box_out = td.Box.from_bounds(

rmin=(-Lx / 2 + t + radius - wmid / 2, -Ly / 2 - 1, -h / 2),

rmax=(-Lx / 2 + t + radius + wmid / 2, -Ly / 2 + t, +h / 2),

)

geo_sub = td.Box.from_bounds(

rmin=(-td.inf, -td.inf, -10000),

rmax=(+td.inf, +td.inf, -h / 2),

)

wg_in = td.Structure(geometry=box_in, medium=td.Medium(permittivity=n_wg**2))

wg_out = td.Structure(geometry=box_out, medium=td.Medium(permittivity=n_wg**2))

substrate = td.Structure(geometry=geo_sub, medium=td.Medium(permittivity=n_sub**2))

Fabrication Constraints#

With the current parameterization, it is possible to generate structures with wildly varying radii of curvature which may be difficult to fabricate. To alleviate this, we introduce a minimum radius of curvature penalty transformation using the tidy3d autograd utilities. The penalty will take a set of vertices, compute the local radius of curvature using a quadratic Bezier curve, and return an average penalty function that depends on how much smaller the local radii are compared to a desired

minimum radius.

[13]:

from tidy3d.plugins.autograd import make_curvature_penalty

penalty = make_curvature_penalty(min_radius)

We then wrap this penalty to look at only the inner and outer vertices independently and average the penalty from each.

[14]:

def eval_penalty(params):

"""Evaluate penalty on a set of params looking at radius of curvature."""

vertices = make_vertices(params)

_vertices = anp.array(vertices)

vertices_top = _vertices[1 : num_pts + 3] # select outer set of points along bend

vertices_bot = _vertices[num_pts + 4 :] # select inner set of points along bend

penalty_top = penalty(vertices_top)

penalty_bot = penalty(vertices_bot)

return (penalty_top + penalty_bot) / 2.0

Let’s try this out on our starting parameters. We see we get an autograd traced float that seems reasonably low given our smooth starting structure.

[15]:

eval_penalty(params)

[15]:

np.float64(3.57973410373255e-23)

Define Simulation#

Now we define our sources, monitors, and simulation.

We first define a mode source injected at the input waveguide.

[16]:

mode_width = wmid + 2 * spc

mode_height = Lz

mode_src = td.ModeSource(

size=(0, mode_width, mode_height),

center=(-Lx / 2 + t / 2, -Ly / 2 + t + radius, 0),

direction="+",

source_time=td.GaussianPulse(

freq0=freq0,

fwidth=fwidth,

),

)

Next, we define monitors for storing:

The output mode amplitude at the central frequency.

The flux on the output plane (for reference).

The output mode amplitude across a frequency range (for examining the transmission spectrum of our final device).

A field monitor to measure fields directly in the z-normal plane intersecting the waveguide.

[17]:

mode_mnt = td.ModeMonitor(

size=(mode_width, 0, mode_height),

center=(-Lx / 2 + t + radius, -Ly / 2 + t / 2, 0),

name=monitor_name,

freqs=[freq0],

mode_spec=mode_spec,

)

flux_mnt = td.FluxMonitor(

size=(mode_width, 0, mode_height),

center=(-Lx / 2 + t + radius, -Ly / 2 + t / 2, 0),

name="flux",

freqs=[freq0],

)

mode_mnt_bb = td.ModeMonitor(

size=(mode_width, 0, mode_height),

center=(-Lx / 2 + t + radius, -Ly / 2 + t / 2, 0),

name="mode_bb",

freqs=freqs.tolist(),

mode_spec=mode_spec,

)

fld_mnt = td.FieldMonitor(

size=(td.inf, td.inf, 0),

freqs=[freq0],

name="field",

)

Next we put everything together into a function that returns a td.Simulation given our parameters and an optional boolean specifying whether to include the field monitor (to save data when fields are not required).

[18]:

def make_sim(params, use_fld_mnt: bool = True) -> td.Simulation:

monitors = [mode_mnt_bb, flux_mnt]

if use_fld_mnt:

monitors += [fld_mnt]

ring = make_structure(params)

return td.Simulation(

size=(Lx, Ly, Lz),

structures=[substrate, wg_in, wg_out, ring],

sources=[mode_src],

grid_spec=td.GridSpec.auto(min_steps_per_wvl=min_steps_per_wvl),

boundary_spec=td.BoundarySpec.pml(x=True, y=True, z=True),

monitors=monitors + [mode_mnt],

run_time=10 / fwidth,

)

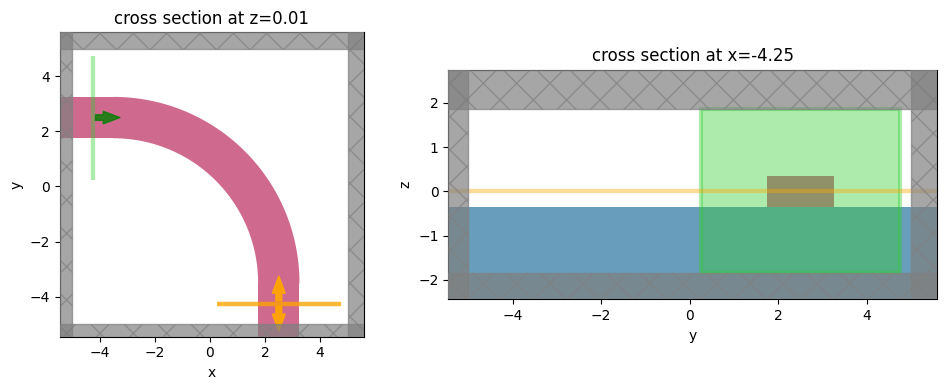

Let’s try it out and plot our simulation.

[19]:

sim = make_sim(params)

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

ax = sim.plot(z=0.01, ax=ax1)

ax = sim.plot(x=-Lx / 2 + t / 2, ax=ax2)

13:58:31 CEST WARNING: Structure: simulation.structures[3] (no `name` was specified) was detected as being less than half of a central wavelength from a PML on side x-min. To avoid inaccurate results or divergence, please increase gap between any structures and PML or fully extend structure through the pml.

WARNING: Suppressed 1 WARNING message.

[20]:

# let's turn off warnings because we know this ring is intersecting with our waveguide ports.

td.config.logging.level = "ERROR"

Select the desired waveguide mode#

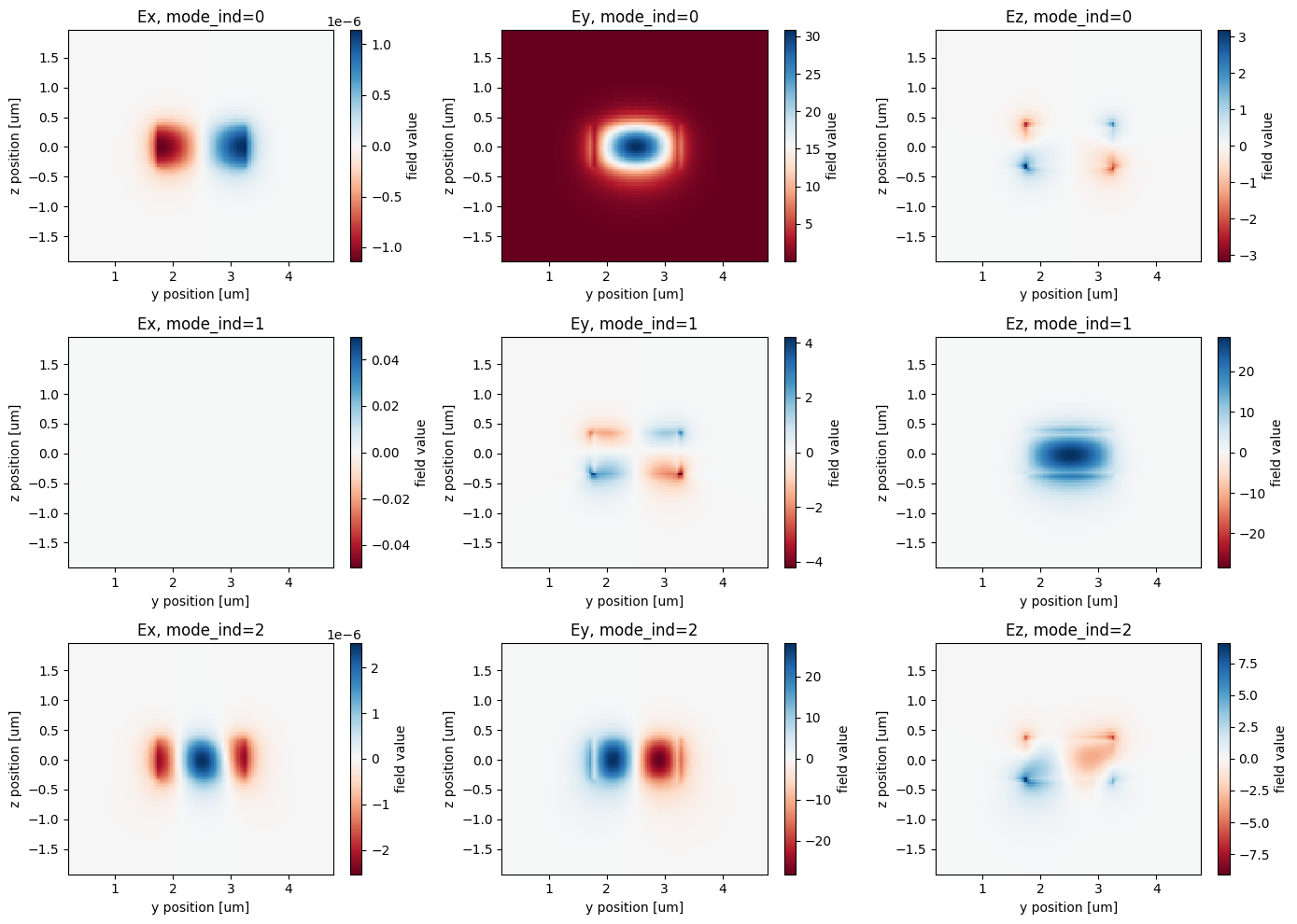

Next, we use the ModeSolver to solve and select the mode_index that gives us the proper injected and measured modes. We plot all of the fields for the first 3 modes and see that the TE0 mode is mode_index=0.

[21]:

from tidy3d.plugins.mode import ModeSolver

ms = ModeSolver(simulation=sim, plane=mode_src, mode_spec=mode_spec, freqs=mode_mnt.freqs)

data = ms.solve()

print("Effective index of computed modes: ", np.array(data.n_eff))

fig, axs = plt.subplots(num_modes, 3, figsize=(14, 10), tight_layout=True)

for mode_ind in range(num_modes):

for field_ind, field_name in enumerate(("Ex", "Ey", "Ez")):

field = data.field_components[field_name].sel(mode_index=mode_ind)

ax = axs[mode_ind, field_ind]

field.real.plot(x="y", y="z", ax=ax, cmap="RdBu")

ax.set_title(f"{field_name}, mode_ind={mode_ind}")

Effective index of computed modes: [[1.79689322 1.75290062 1.60455164]]

Since this is already the default mode index, we can leave the original make_sim() function as is. However, to generate a new mode source with a different mode_index, we could do the following and rewrite that function with the returned mode_src.

[22]:

# select the mode index

mode_index = 0

# make the mode source with appropriate mode index

mode_src = ms.to_source(

mode_index=mode_index,

source_time=mode_src.source_time,

direction=mode_src.direction,

)

Defining objective function#

Now we can define our objective function to maximize. The objective function first generates a simulation given the parameters, runs the simulation using the builtin web.run() function, measures the power transmitted into the TE0 output mode at our desired polarization, and then subtracts the radius of curvature penalty that we defined earlier.

[23]:

def objective(params: np.ndarray, use_fld_mnt: bool = True) -> float:

sim = make_sim(params, use_fld_mnt=use_fld_mnt)

sim_data = web.run(sim, task_name="bend", verbose=False)

# be sure to take .values here before summing the transmission

amps = sim_data[monitor_name].amps.sel(direction="-", mode_index=mode_index).values

transmission = anp.abs(anp.array(amps)) ** 2

J = anp.sum(transmission) - eval_penalty(params)

return J

Next, we use autograd.value_and_grad to transform this objective function into a function that returns the

Objective function evaluated at the passed parameters.

Gradient of the objective function with respect to the passed parameters.

[24]:

val_grad = ag.value_and_grad(objective)

Let’s run this function and take a look at the outputs.

[25]:

val, grad = val_grad(params)

[26]:

print(val)

print(grad)

0.5687336420935004

[-0.01865892 -0.02963101 -0.03688513 -0.05131805 -0.05879448 -0.07076664

-0.07988568 -0.08874235 -0.09495222 -0.09854238 -0.09966801 -0.097961

-0.09220932 -0.08171186 -0.07357111 -0.05781953 -0.04004239 -0.02345049

-0.0070686 0.00911027 0.02499316 0.04011592 0.05224039 0.06249899

0.07394873 0.08152266 0.08699041 0.09041283 0.09348267 0.09340516

0.09340509 0.09348247 0.09041246 0.08698984 0.08152195 0.07394791

0.06249814 0.05223956 0.04011526 0.02499284 0.00911054 -0.00706752

-0.02344846 -0.04003927 -0.05781538 -0.07356634 -0.0817074 -0.09220601

-0.09795997 -0.09967042 -0.09854914 -0.09496389 -0.08875951 -0.07990781

-0.0707935 -0.0588243 -0.05135054 -0.03691525 -0.0296628 -0.01869109]

These seem reasonable and can now be used for plugging into our optimization algorithm.

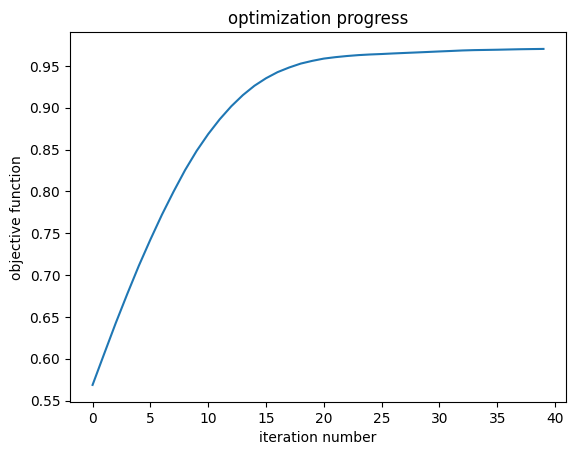

Optimization Procedure#

With our gradients defined, we write a simple optimization loop using the optax package. We use the adam method with a tunable number of steps and learning rate. The intermediate values, parameters, and data are stored for visualization later.

Note: this will take several minutes. While not shown here, it is good practice to checkpoint your optimization results by saving to file on every iteration, or ensure you have a stable internet connection. See this notebook for more details.

[27]:

import optax

# hyperparameters

num_steps = 40

learning_rate = 0.01

# initialize adam optimizer with starting parameters

params = np.array(params).copy()

optimizer = optax.adam(learning_rate=learning_rate)

opt_state = optimizer.init(params)

# store history

objective_history = []

param_history = [params]

data_history = []

for i in range(num_steps):

# compute gradient and current objective function value

value, gradient = val_grad(params)

# outputs

print(f"step = {i + 1}")

print(f"\tJ = {value:.4e}")

print(f"\tgrad_norm = {np.linalg.norm(gradient):.4e}")

# compute and apply updates to the optimizer based on gradient

updates, opt_state = optimizer.update(-gradient, opt_state, params)

params[:] = optax.apply_updates(params, updates)

# save history

objective_history.append(value)

param_history.append(params)

step = 1

J = 5.6873e-01

grad_norm = 5.4152e-01

step = 2

J = 6.0577e-01

grad_norm = 5.3089e-01

step = 3

J = 6.4252e-01

grad_norm = 5.1894e-01

step = 4

J = 6.7751e-01

grad_norm = 5.0543e-01

step = 5

J = 7.1123e-01

grad_norm = 4.8599e-01

step = 6

J = 7.4261e-01

grad_norm = 4.6454e-01

step = 7

J = 7.7245e-01

grad_norm = 4.4225e-01

step = 8

J = 7.9989e-01

grad_norm = 4.1895e-01

step = 9

J = 8.2573e-01

grad_norm = 3.9194e-01

step = 10

J = 8.4871e-01

grad_norm = 3.6316e-01

step = 11

J = 8.6870e-01

grad_norm = 3.3433e-01

step = 12

J = 8.8646e-01

grad_norm = 3.0390e-01

step = 13

J = 9.0180e-01

grad_norm = 2.7200e-01

step = 14

J = 9.1482e-01

grad_norm = 2.4054e-01

step = 15

J = 9.2575e-01

grad_norm = 2.1075e-01

step = 16

J = 9.3422e-01

grad_norm = 1.8431e-01

step = 17

J = 9.4098e-01

grad_norm = 1.6023e-01

step = 18

J = 9.4606e-01

grad_norm = 1.3917e-01

step = 19

J = 9.5004e-01

grad_norm = 1.2206e-01

step = 20

J = 9.5260e-01

grad_norm = 1.1024e-01

step = 21

J = 9.5467e-01

grad_norm = 1.0258e-01

step = 22

J = 9.5604e-01

grad_norm = 9.8921e-02

step = 23

J = 9.5692e-01

grad_norm = 9.7953e-02

step = 24

J = 9.5776e-01

grad_norm = 9.9126e-02

step = 25

J = 9.5846e-01

grad_norm = 1.0089e-01

step = 26

J = 9.5904e-01

grad_norm = 1.0259e-01

step = 27

J = 9.5974e-01

grad_norm = 1.0434e-01

step = 28

J = 9.6040e-01

grad_norm = 1.0569e-01

step = 29

J = 9.6103e-01

grad_norm = 1.0657e-01

step = 30

J = 9.6190e-01

grad_norm = 1.0442e-01

step = 31

J = 9.6284e-01

grad_norm = 9.9270e-02

step = 32

J = 9.6383e-01

grad_norm = 9.3306e-02

step = 33

J = 9.6463e-01

grad_norm = 8.7468e-02

step = 34

J = 9.6553e-01

grad_norm = 8.1486e-02

step = 35

J = 9.6624e-01

grad_norm = 7.5130e-02

step = 36

J = 9.6685e-01

grad_norm = 6.8947e-02

step = 37

J = 9.6727e-01

grad_norm = 6.3316e-02

step = 38

J = 9.6767e-01

grad_norm = 5.8440e-02

step = 39

J = 9.6791e-01

grad_norm = 5.4734e-02

step = 40

J = 9.6820e-01

grad_norm = 5.1895e-02

Analyzing results#

After the optimization is finished, let’s look at the results.

[28]:

_ = plt.plot(objective_history)

ax = plt.gca()

ax.set_xlabel("iteration number")

ax.set_ylabel("objective function")

ax.set_title("optimization progress")

plt.show()

Next, we can grab our initial and final device from the history lists.

[29]:

sim_start = make_sim(param_history[0])

data_start = web.run(sim_start, task_name="start")

sim_final = make_sim(param_history[-1])

data_final = web.run(sim_final, task_name="final")

14:47:23 CEST Created task 'start' with task_id 'fdve-001602d0-ce97-4b58-9e89-1812b152a3ec' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-001602d0-ce 97-4b58-9e89-1812b152a3ec'.

Task folder: 'default'.

14:47:25 CEST Maximum FlexCredit cost: 0.029. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

14:47:26 CEST status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

14:47:35 CEST status = preprocess

14:47:40 CEST starting up solver

running solver

14:47:46 CEST early shutoff detected at 32%, exiting.

14:47:47 CEST status = postprocess

14:47:49 CEST status = success

14:47:51 CEST View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-001602d0-ce 97-4b58-9e89-1812b152a3ec'.

14:47:54 CEST loading simulation from simulation_data.hdf5

Created task 'final' with task_id 'fdve-a2027ca4-200d-49e9-b8fd-8a454d63c256' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-a2027ca4-20 0d-49e9-b8fd-8a454d63c256'.

Task folder: 'default'.

14:47:56 CEST Maximum FlexCredit cost: 0.029. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

14:47:57 CEST status = success

14:48:00 CEST loading simulation from simulation_data.hdf5

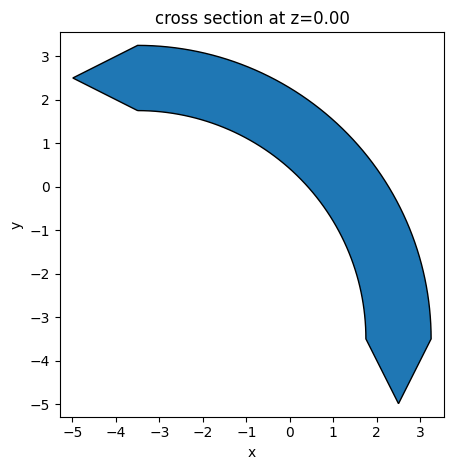

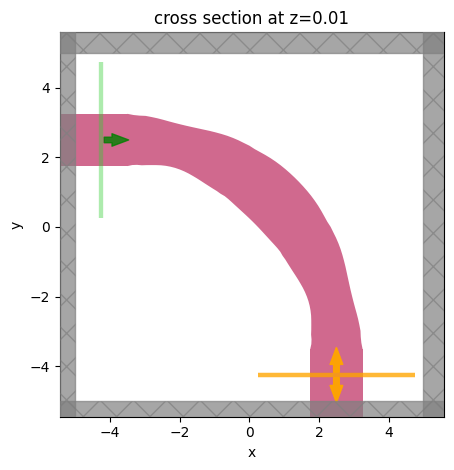

Let’s take a look at the final structure. We see that it has a smooth design which is symmetric about the 45 degree angle.

[30]:

ax = sim_final.plot(z=0.01)

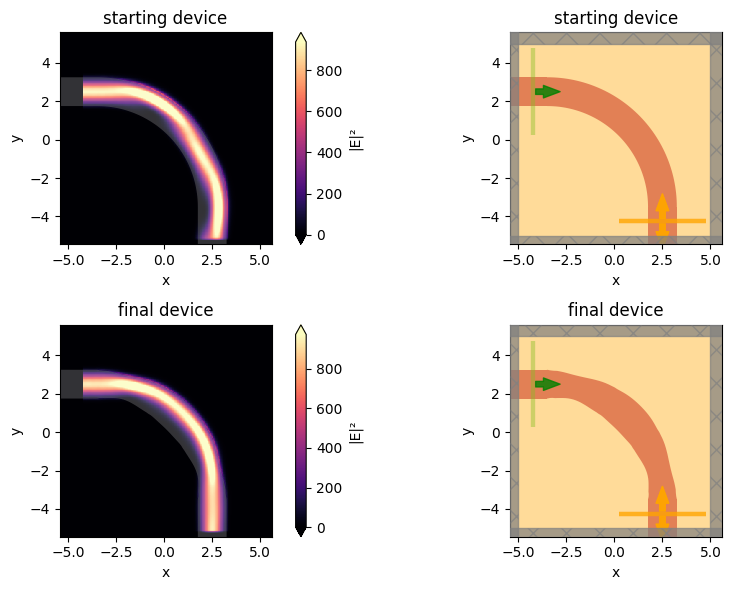

Now let’s inspect the difference between the initial and final intensity patterns. We notice that the final device is quite effective at coupling light into the output waveguide! This is especially evident when compared to the starting device.

[31]:

f, ((ax1, ax2), (ax3, ax4)) = plt.subplots(2, 2, tight_layout=True, figsize=(10, 6))

_ = data_start.plot_field("field", "E", "abs^2", ax=ax1)

_ = sim_start.plot(z=0, ax=ax2)

ax1.set_title("starting device")

ax2.set_title("starting device")

_ = data_final.plot_field("field", "E", "abs^2", ax=ax3)

_ = sim_final.plot(z=0, ax=ax4)

ax3.set_title("final device")

ax4.set_title("final device")

plt.show()

Let’s view the transmission now, both in linear and dB scale.

The mode amplitudes are simply an xarray.DataArray that can be selected, post processed, and plotted.

[32]:

amps = data_final["mode_bb"].amps.sel(direction="-", mode_index=mode_index)

[33]:

transmission = abs(amps) ** 2

transmission_percent = 100 * transmission

print(f"transmission of {transmission_percent.values[0]:.3f} %")

transmission of 96.856 %

Export to GDS#

The Simulation object has the .to_gds_file convenience function to export the final design to a GDS file. In addition to a file name, it is necessary to set a cross-sectional plane (z = 0 in this case) on which to evaluate the geometry. See the GDS export notebook for a detailed

example on using .to_gds_file and other GDS related functions.

[34]:

sim_final.to_gds_file(

fname="./misc/inverse_des_wg_bend.gds",

z=0,

)