Broadband polarizer assisted by anisotropic metamaterial#

Silicon photonic polarizers are specialized optical devices designed to filter, control, and manipulate the polarization state of light in integrated photonic circuits. Comprising carefully engineered silicon waveguide structures, these polarizers play a crucial role in ensuring the efficient and reliable operation of various optical communication and sensing systems. Over the years, various silicon photonic polarizer designs have been proposed. However, most designs suffer from a narrow working bandwidth or a large device footprint.

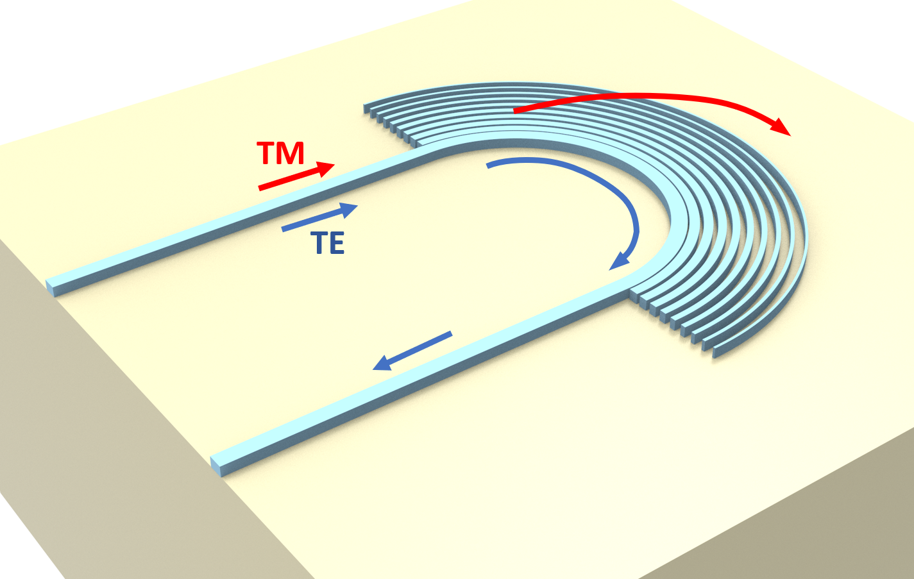

A polarizer design demonstrated by Hongnan Xu, Daoxin Dai, and Yaocheng Shi, "Anisotropic metamaterial-assisted all-silicon polarizer with 415-nm bandwidth," *Photon. Res.* 7, 1432-1439 (2019), DOI: 10.1364/PRJ.7.001432 utilizes anisotropic subwavelength grating (SWG) metamaterial cladding to a 180 degree waveguide bend. This polarizer design preserves the TE mode and filters out TM mode in a broad wavelength range of 400 nm. The footprint of the

device is also more compact than many of the previous designs.

For more integrated photonic examples such as the 8-Channel mode and polarization de-multiplexer, the broadband bi-level taper polarization rotator-splitter, and the broadband directional coupler, please visit our examples page.

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials.

[1]:

import numpy as np

import matplotlib.pyplot as plt

import gdstk

import tidy3d as td

import tidy3d.web as web

Effective Anisotropic Refractive Index Tensor of the SWG#

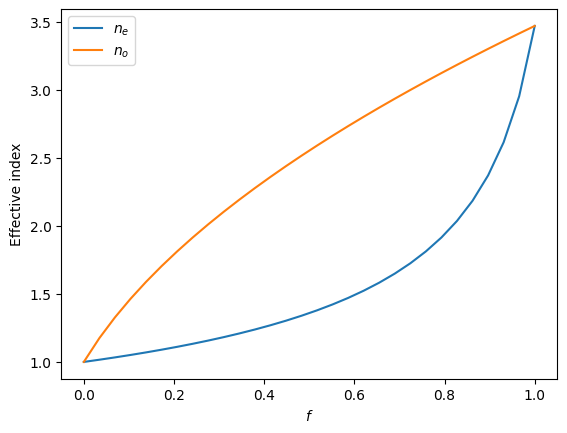

For this device, first we are going to make a regular 180 degree waveguide bend. In the bending region, we are going to add an SWG metamaterial parallel to the bend. The SWG metamaterial acts as an effective medium with an anisotropic refractive index tensor. The ordinary and extraordinary refractive indices are given by the well known Rytov’s approximation: \(1/n_e^2=f/n_{si}^2+(1-f)/n_{air}^2\) and \(n_o^2=fn_{si}^2+(1-f)n_{air}^2\), where \(f\) is the duty cycle of the SWG. We can investigate how the effective indices vary with \(f\).

From the result, we notice that \(n_0\) is much larger than \(n_e\) when \(f\) is not close to 0 or 1. Since the TE waveguide mode has the electric field primarily in the extraordinary direction while the TM mode has the electric field primarily in the ordinary direction, they will feel very different refractive index in the SWG metamaterial. For TE mode, the refractive index is much lower than \(n_{si}\) so it should stay guided inside the waveguide. For TM mode, on the other hand, the effective refractive index is close to \(n_{si}\) so it will be guided into the SWG metamaterial region and radiates out. This way, the waveguide bend together with the SWG metamaterial functions as a polarizer that passes TE mode and suppresses TM mode.

For a more detailed discussion, please refer to the reference.

[2]:

n_si = 3.47

f = np.linspace(0, 1, 30)

n_e = np.sqrt(1 / (f / n_si**2 + (1 - f)))

n_o = np.sqrt(f * n_si**2 + (1 - f))

plt.plot(f, n_e, label="$n_e$")

plt.plot(f, n_o, label="$n_o$")

plt.xlabel("$f$")

plt.ylabel("Effective index")

plt.legend()

plt.show()

Structure Setup#

The simulation wavelength range is from 1260 nm to 1675 nm.

[3]:

lda_min = 1.26 # minimal wavelength

lda_max = 1.675 # maximal wavelength

lda0 = (lda_min + lda_max) / 2 # central wavelength

freqs = np.linspace(td.C_0 / lda_max, td.C_0 / lda_min, 301) # frequency range

freq0 = td.C_0 / lda0 # central frequency

fwidth = 0.4 * (td.C_0 / lda_min - td.C_0 / lda_max) # width of the frequency range of the source

Next, we define the media used in the simulation. Since the simulation is very broadband, it is better to use dispersive media. We can use the crystalline silicon and silicon dioxide from Tidy3D’s built-in material library.

[4]:

si = td.material_library["cSi"]["Li1993_293K"]

sio2 = td.material_library["SiO2"]["Horiba"]

The silicon layer has a thickness of 250 nm. To stay at single mode operation, the waveguide width is chosen to be 360 nm. The design parameters such as waveguide bend radius, period of the SWG, maximal and minimal duty cycles, and the number of SWG layers need to be optimized for the design. This is explored in the reference. Here we report the optimized parameters.

[5]:

h_si = 0.25 # silicon layer thickness

w_wg = 0.36 # waveguide width

R_0 = 3.5 # radius of the waveguide bend

p = 0.3 # period of the SWG

f_M = 0.75 # maximal duty cycle

f_m = 0.2 # minimal duty cycle

N = 9 # number of SWG layers

inf_eff = 1e3 # effective infinity

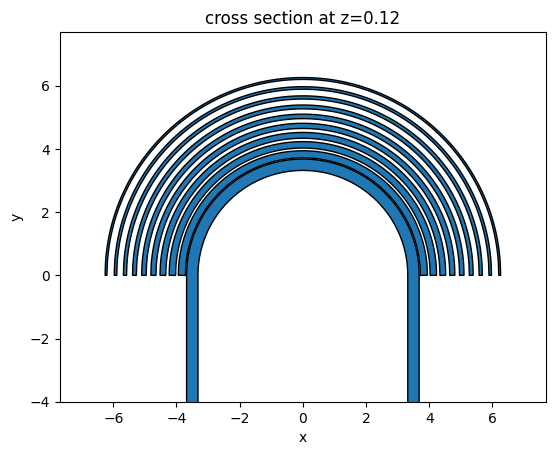

The radius of the \(i\)-th SWG layer is given by \(R_i = R_0 + w_wg/2 + p(i-1/2)\) and the duty cycle of the layer is also given by a linear ramping \(f_i=f_M+(f_m-f_M)(i-1)/(N-1)\). The width of the waveguide in each SWG layer is thus given by \(pf_i\).

[6]:

R_is = [R_0 + w_wg / 2 + p * (i - 0.5) for i in range(1, N + 1)] # radius of each SWG layer

f_is = [

f_M + (f_m - f_M) * (i - 1) / (N - 1) for i in range(1, N + 1)

] # duty cycle of each SWG layer

w_is = [p * f for f in f_is] # waveguide width of each SWG layer

# insert the circular waveguide band into the list

R_is.insert(0, R_0)

w_is.insert(0, w_wg)

With all the parameters determined, we can set up the geometries. One easy way is to make use of the gdstk library as demonstrated below.

[7]:

cell = gdstk.Cell("SWG") # define a gds cell

# define a path of each swg layer

for R_i, w_i in zip(R_is, w_is):

points_x = np.linspace(-R_i, R_i, 1001) # x coordinates of the waveguide in the swg layer

points_y = np.sqrt(R_i**2 - points_x**2) # y coordinates

# if it's the innermost waveguide bend, add two points to the coordinates to include the straight waveguides

if R_i == R_0:

points_x = np.insert(points_x, 0, -R_0)

points_y = np.insert(points_y, 0, -inf_eff)

points_x = np.append(points_x, R_0)

points_y = np.append(points_y, -inf_eff)

points = points_x + 1j * points_y

# add the path to the cell

cell.add(gdstk.FlexPath(points, w_i, layer=1, datatype=0))

[8]:

# define geometry from the paths in the cell

device_geo = td.PolySlab.from_gds(

cell,

gds_layer=1,

axis=2,

slab_bounds=(0, h_si),

)

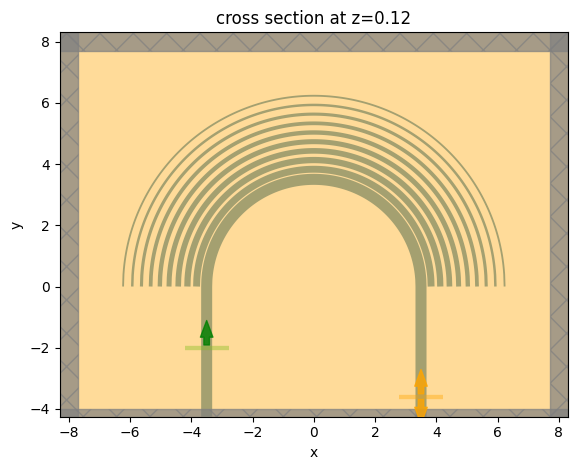

To make sure the geometries are defined correctly, we can plot them first. From the plot, it indeed looks like the correct device.

[9]:

l_straight = 4

pad = lda0

fig, ax = plt.subplots()

for geo in device_geo:

geo.plot(z=h_si / 2, ax=ax)

ax.set_ylim(-l_straight, R_is[-1] + pad)

ax.set_xlim(-R_is[-1] - pad, R_is[-1] + pad)

plt.show()

Lastly, we define Tidy3D Structures from the geometries. A silicon dioxide substrate structure is also defined.

[10]:

device_structure = [td.Structure(geometry=geo, medium=si) for geo in device_geo]

substrate = td.Structure(

geometry=td.Box.from_bounds(rmin=(-inf_eff, -inf_eff, -inf_eff), rmax=(inf_eff, inf_eff, 0)),

medium=sio2,

)

TE Input Simulation#

To fully characterize the device performance, we need to simulate two cases: TE input and TM input. First, let’s set up the simulation for the TE input. A ModeSource is defined to inject the TE mode at the input waveguide by setting mode_index=0. Note that since the simulation is quite broadband, we use a broadband source by setting num_freqs = 10, which accounts for the frequency-dependent mode profile.

[11]:

# define a mode source that injects the fundamental te mode

mode_spec = td.ModeSpec(num_modes=2, target_neff=n_si)

mode_source = td.ModeSource(

center=(-R_0, -l_straight / 2, h_si / 2),

size=(4 * w_wg, 0, 4 * h_si),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=mode_spec,

mode_index=0,

num_freqs=10,

)

# define a mode monitor to measure the transmission of the mode

mode_monitor = td.ModeMonitor(

center=(R_0, -l_straight * 0.9, h_si / 2),

size=mode_source.size,

freqs=freqs,

mode_spec=mode_spec,

name="mode",

)

lda_field = 1.55 # frequency at which field is monitored

# define a field monitor to visualize mode propagation

field_monitor = td.FieldMonitor(

center=(0, 0, h_si / 2), size=(td.inf, td.inf, 0), freqs=[td.C_0 / lda_field], name="field"

)

[16:32:58] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

Define a Tidy3D Simulation.

[12]:

# simulation domain size

Lx = 2 * (R_is[-1] + pad)

Ly = l_straight + R_is[-1] + pad

Lz = 8 * h_si

run_time = 1e-12 # simulation run time

# define a simulation

sim_te = td.Simulation(

center=(0, 0.5 * (R_is[-1] + pad - l_straight), 0),

size=(Lx, Ly, Lz),

grid_spec=td.GridSpec.auto(min_steps_per_wvl=20, wavelength=lda0),

structures=device_structure + [substrate],

sources=[mode_source],

monitors=[mode_monitor, field_monitor],

run_time=run_time,

)

Visualize the simulation setup before submitting it to the server.

[13]:

sim_te.plot(z=h_si / 2)

plt.show()

Submit the simulation to the server.

[14]:

job = web.Job(simulation=sim_te, task_name="TE_mode")

sim_data_te = job.run(path="data/simulation_data.hdf5")

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 9f8e016c-918d-4504-a6c7-b4fa9229596dv1'.

TM Input Simulation#

Before analyzing the simulation result for the TE input case, let’s run the TM input case first. To have a TM input simulation, we only need to update the mode_index to 1 in the ModeSource. This can be done easily by copying the previous simulation.

[15]:

mode_source = mode_source.copy(

update={"mode_index": 1}

) # copy the mode source and update mode_index

sim_tm = sim_te.copy(update={"sources": [mode_source]}) # copy the simulation and update the source

job = web.Job(simulation=sim_tm, task_name="TM_mode")

sim_data_tm = job.run(path="data/simulation_data.hdf5")

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- d44f5e5e-8cfa-4ffb-801f-4754e74e0fcav1'.

Result Analysis#

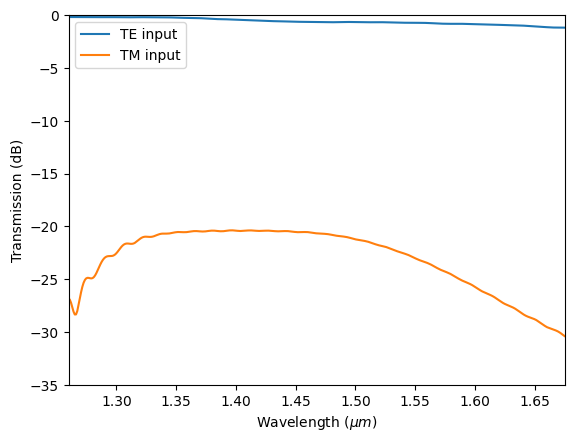

Now that both simulations are complete, let’s visualize the results. First, we plot the transmission spectra. We see that in the TE input, transmission is close to 0 dB while in the TM input case, transmission is below -20 dB. This is the desirable outcome for a polarizer.

[16]:

amp_te = sim_data_te["mode"].amps.sel(mode_index=0, direction="-")

T_te = np.abs(amp_te) ** 2

amp_tm = sim_data_tm["mode"].amps.sel(mode_index=1, direction="-")

T_tm = np.abs(amp_tm) ** 2

plt.plot(td.C_0 / freqs, 10 * np.log10(T_te), label="TE input")

plt.plot(td.C_0 / freqs, 10 * np.log10(T_tm), label="TM input")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Transmission (dB)")

plt.ylim(-35, 0)

plt.xlim(lda_min, lda_max)

plt.legend()

plt.show()

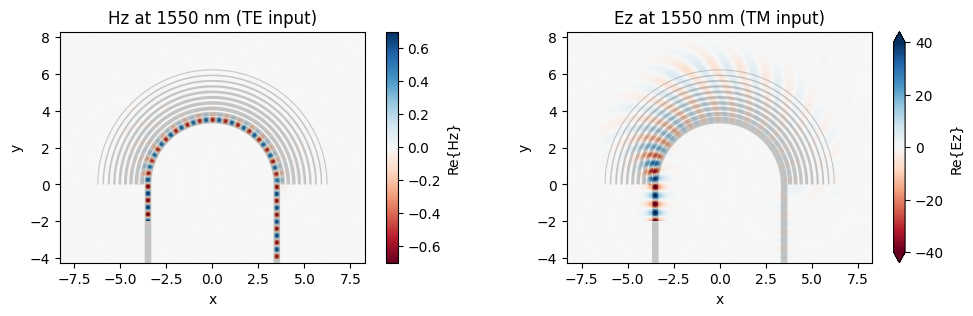

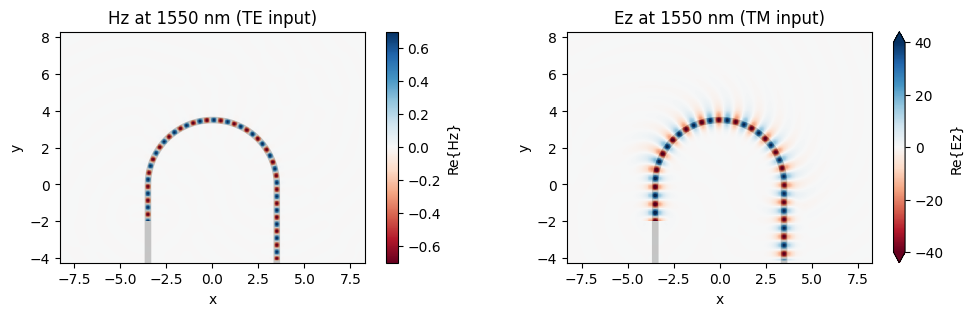

We go on to plot the field distributions at 1550 nm in the two simulations. The TE mode (left plot) stays guided inside the waveguide bend and thus the transmission is high. The TM mode (right plot), on the other hand, is leaked into the SWG metamaterial region and radiates to free space eventually, leading to a low transmission.

[17]:

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(12, 3))

sim_data_te.plot_field(field_monitor_name="field", field_name="Hz", vmin=-0.7, vmax=0.7, ax=ax1)

sim_data_tm.plot_field(field_monitor_name="field", field_name="Ez", vmin=-40, vmax=40, ax=ax2)

ax1.set_title("Hz at 1550 nm (TE input)")

ax2.set_title("Ez at 1550 nm (TM input)")

plt.show()

Reference Simulations without SWG#

As a comparison, we can run a baseline reference and simulate the same waveguide bend without the SWG metamaterial cladding. We only need to copy the previous simulations and update the structure such that they don’t contain the SWG.

To further speed up the simulation, we put the TE and TM input cases into a batch and run them on the server simultaneously.

[18]:

# copy previous simulations and update the structures

sim_te_ref = sim_te.copy(update={"structures": [device_structure[0], substrate]})

sim_tm_ref = sim_tm.copy(update={"structures": [device_structure[0], substrate]})

# make a batch and run it

sims = {

"TE": sim_te_ref,

"TM": sim_tm_ref,

}

batch = web.Batch(simulations=sims, verbose=True)

batch_results = batch.run(path_dir="data")

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- cf53b5fa-6795-45b2-87ee-a8304cddea46v1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 2db2e385-f319-40ab-8f2b-aaae78dd4a3bv1'.

[16:41:47] Started working on Batch. container.py:475

[16:41:56] Maximum FlexCredit cost: 0.418 for the whole batch. container.py:479 Use 'Batch.real_cost()' to get the billed FlexCredit cost after the Batch has completed.

[16:43:40] Batch complete. container.py:522

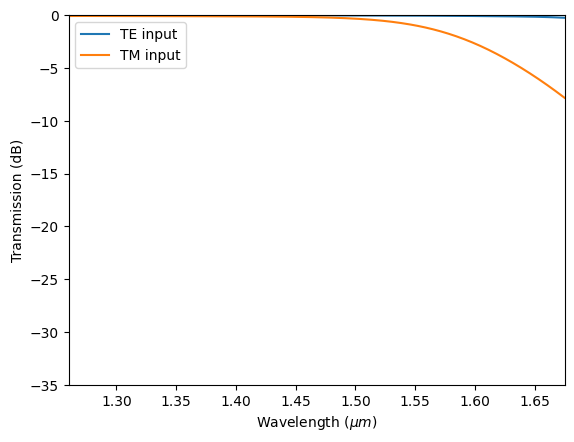

Lastly, we plot the same results. Without SWG, we see that both the TE and TM mode transmissions are high. Adding the SWG indeed couples the TM mode out of the waveguide.

[19]:

amp_te_ref = batch_results["TE"]["mode"].amps.sel(mode_index=0, direction="-")

T_te_ref = np.abs(amp_te_ref) ** 2

amp_tm_ref = batch_results["TM"]["mode"].amps.sel(mode_index=1, direction="-")

T_tm_ref = np.abs(amp_tm_ref) ** 2

plt.plot(td.C_0 / freqs, 10 * np.log10(T_te_ref), label="TE input")

plt.plot(td.C_0 / freqs, 10 * np.log10(T_tm_ref), label="TM input")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Transmission (dB)")

plt.ylim(-35, 0)

plt.xlim(lda_min, lda_max)

plt.legend()

plt.show()

[20]:

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(12, 3))

batch_results["TE"].plot_field(

field_monitor_name="field", field_name="Hz", vmin=-0.7, vmax=0.7, ax=ax1

)

batch_results["TM"].plot_field(

field_monitor_name="field", field_name="Ez", vmin=-40, vmax=40, ax=ax2

)

ax1.set_title("Hz at 1550 nm (TE input)")

ax2.set_title("Ez at 1550 nm (TM input)")

plt.show()

[ ]: