8-Channel mode and polarization de-multiplexer#

Note: the cost of running the entire notebook is larger than 1 FlexCredit.

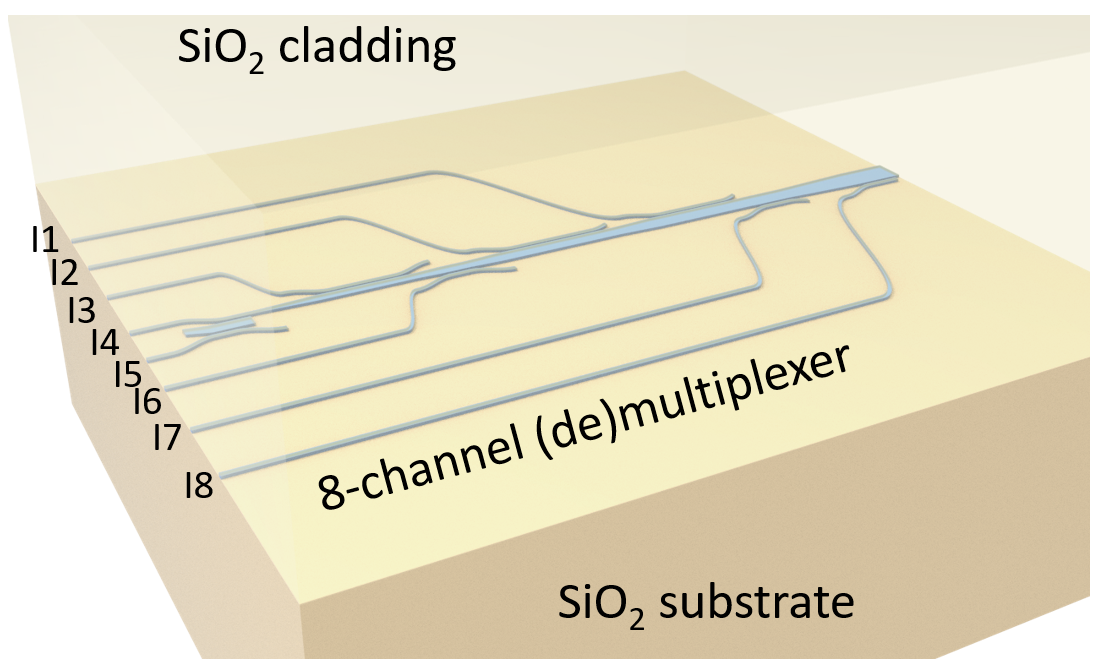

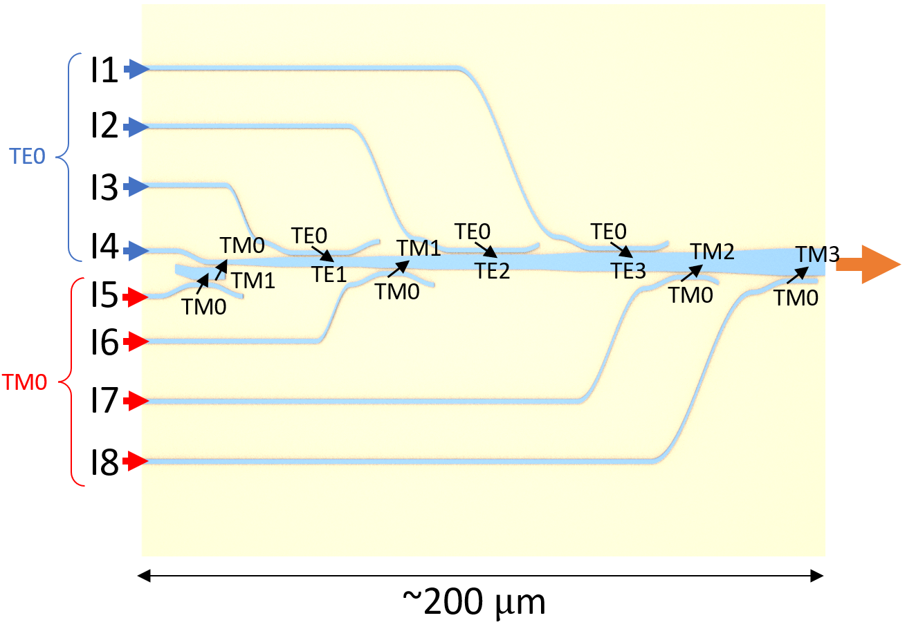

Mode-division multiplexing and polarization-division multiplexing on integrated photonic circuits are critical for large-bandwidth and high-speed optical communication networks. Here we introduce an 8-channel mode and polarization (de)multiplexer that is based on asymmetric directional couplers that operate on TE0 to TE3 as well as TM0 to TM3 modes. The design is based on Wang, J., He, S. and Dai, D. (2014), On-chip silicon 8-channel hybrid (de)multiplexer enabling simultaneous mode- and polarization-division-multiplexing. Laser & Photonics Reviews, 8: L18-L22.

The notebook is organized as the following:

First, we use Tidy3D’s ModeSolver to simulate the effective indices of the eight modes as a function of waveguide width. From the result, we can obtain the width of the bus waveguide in each directional coupler section to satisfy the phase match condition.

Then, we model each directional coupler section individually to ensure good mode conversion efficiency.

Lastly, once we confirm that good performance is achieved on each section, we build the whole 8-channel (de)multiplexer and simulate the whole device, which is about 200 \(\mu m\) in length. Thanks to the fast speed of Tidy3D solver, large simulations like these can be handled easily.

The models in this notebook contain many waveguide bends. These bends can be defined natively in Tidy3D as demonstrated in the Euler waveguide bend example or the waveguide Y junction example. Alternatively, it is often easier to make use of gdstk as shown in the GDSII import

tutorial. Here we will also demonstrate how to use gdstk to define the structures used in the simulation.

For more integrated photonic examples, please visit our examples page. If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials. FDTD simulations can diverge due to various reasons. If you run into any simulation divergence issues, please follow the steps outlined in our troubleshooting guide to resolve it.

[1]:

import numpy as np

import matplotlib.pyplot as plt

from matplotlib.gridspec import GridSpec

import gdstk

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins.mode import ModeSolver

The ModeSolver will check if the solved mode fields decay at the boundaries. When the field does not decay, a warning will be thrown. When we solve for more modes than the waveguide can support, spurious modes will appear and their fields most likely won’t decay at the boundaries. We set the logging level to "ERROR" mainly to avoid these warnings.

In general, we do not recommend setting the logging level to "ERROR" since most warnings are informative and can help troubleshoot your simulations.

[2]:

td.config.logging_level = "ERROR"

Mode Indices Calculation#

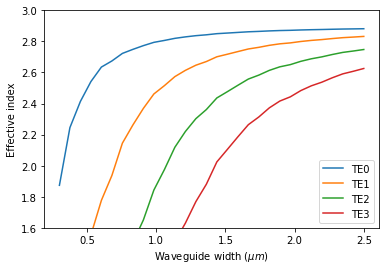

To obtain the width of the bus waveguide in each asymmetric directional coupler, we need to first calculate the relationship between the effective indices of each mode and the waveguide width. This can be achieved by using the ModeSolver from Tidy3D’s plugins. This computation will be done on a local computer so it won’t cost any FlexCredits.

For the entire notebook, we will focus on the central wavelength of 1550 nm and a wavelength range from 1500 nm to 1600 nm.

[3]:

lda0 = 1.55 # central wavelength

ldas = np.linspace(1.5, 1.6, 101) # wavelength range of interest

freq0 = td.C_0 / lda0 # corresponding central frequency

freqs = td.C_0 / ldas # corresponding frequency range

fwidth = 0.5 * (np.max(freqs) - np.min(freqs)) # width of the excitation spectrum

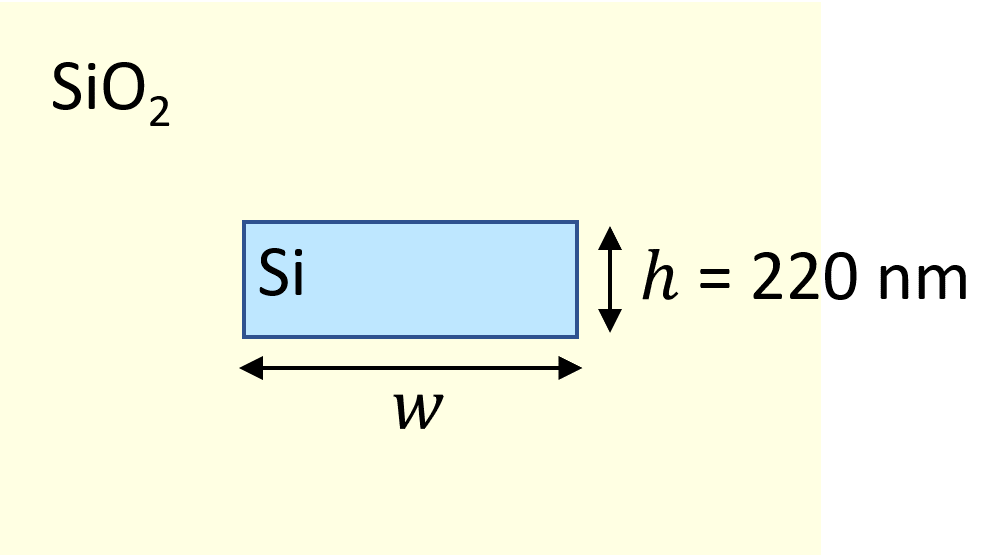

The structure is Si waveguide on silica substrate and top cladding. Therefore, we only need to define two materials. Within the wavelength range of interest, they can be considered lossless and dispersionless.

[4]:

n_si = 3.48 # silicon refractive index

si = td.Medium(permittivity=n_si**2)

n_sio2 = 1.44 # silicon oxide refractive index

sio2 = td.Medium(permittivity=n_sio2**2)

The thickness of the waveguide is the standard 220 nm, which we will use throughout the notebook.

Here we calculate the effective indices for the four TE modes (TE0-TE3) and the four TM modes (TM0-TM3) for waveguide width from 300 nm to 2500 nm.

[5]:

h = 0.22 # waveguide thickness

ws = np.linspace(0.3, 2.5, 30) # range of waveguide width

Define ModeSpec, GridSpec, and BoudnarySpec for the simulations. The number of modes is set to 4 to make sure TE0-TE3 (TM0-TM3) modes are always included, even though when the waveguide width is small, not all modes are supported.

[6]:

N_mode = 4 # number of modes

# define mode spec

mode_spec = td.ModeSpec(num_modes=N_mode, target_neff=n_si)

# define grid spec

grid_spec = td.GridSpec.auto(min_steps_per_wvl=30, wavelength=lda0)

# define boundary spec

bound_spec = td.BoundarySpec.all_sides(boundary=td.PML())

The waveguide structure has a mirror symmetry with respect to the \(xy\) plane. In this case, the TE and TM modes share different symmetries. Therefore, we can solve for the TE and TM separately by imposing the corresponding symmetry in the simulation. This way, the result looks cleaner.

First, we use the (0,0,1) symmetry to get the effective indices of the TE modes. A for loop will be used to iterate over different waveguide widths. At each iteration, the effective indices of the first four TE modes will be calculated.

[7]:

n_eff = np.zeros((len(ws), N_mode)) # placeholder for the effective indices

# loop over the waveguide width and compute the effective indices at each iteration

for i, w in enumerate(ws):

# define the waveguide structure

waveguide = td.Structure(

geometry=td.Box(center=(0, 0, 0), size=(w, td.inf, h)), medium=si

)

sim_size = (6 * w, 1, 8 * h) # simulation domain size

mode_size = (6 * w, 0, 8 * h) # mode plane size

# define simulation

sim = td.Simulation(

size=sim_size,

grid_spec=grid_spec,

structures=[waveguide],

sources=[],

monitors=[],

run_time=1e-11,

boundary_spec=bound_spec,

medium=sio2,

symmetry=(0, 0, 1),

)

# define mode solver

mode_solver = ModeSolver(

simulation=sim,

plane=td.Box(center=(0, 0, 0), size=mode_size),

mode_spec=mode_spec,

freqs=[freq0],

)

# solve for the modes

mode_data = mode_solver.solve()

# obtain the effective indices

n_eff[i] = mode_data.n_eff.values

After the indices are solved, we can plot them for visualization.

[8]:

# plot the effective indices for each TE mode

for i in range(N_mode):

plt.plot(ws, n_eff[:, i])

plt.ylim(1.6, 3)

plt.legend(("TE0", "TE1", "TE2", "TE3"))

plt.xlabel("Waveguide width ($\mu m$)")

plt.ylabel("Effective index")

plt.show()

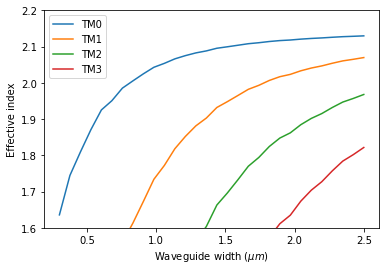

A similar calculation and visualization will be performed for the first TM modes. We simply change the symmetry to (0,0,-1) in this case.

[10]:

for i, w in enumerate(ws):

waveguide = td.Structure(

geometry=td.Box(center=(0, 0, 0), size=(w, td.inf, h)), medium=si

)

sim_size = (6 * w, 1, 8 * h) # simulation domain size

mode_size = (6 * w, 0, 8 * h) # mode plane size

sim = td.Simulation(

size=sim_size,

grid_spec=grid_spec,

structures=[waveguide],

sources=[],

monitors=[],

run_time=1e-11,

boundary_spec=bound_spec,

medium=sio2,

symmetry=(0, 0, -1),

)

mode_solver = ModeSolver(

simulation=sim,

plane=td.Box(center=(0, 0, 0), size=mode_size),

mode_spec=mode_spec,

freqs=[freq0],

)

mode_data = mode_solver.solve()

n_eff[i] = mode_data.n_eff.values

[11]:

for i in range(N_mode):

plt.plot(ws, n_eff[:, i])

plt.ylim(1.6, 2.2)

plt.legend(("TM0", "TM1", "TM2", "TM3"))

plt.xlabel("Waveguide width ($\mu m$)")

plt.ylabel("Effective index")

plt.show()

The input waveguides are designed to be around 400 nm in width. From the plots above, we can determine the bus waveguide width for each asymmetric directional coupler by looking for the width with the same effective index as the 400 nm waveguide.

Individual Directional Coupler#

In this section, we model six asymmetric directional couplers. The first three couplers convert the TE0 mode to the TE1, TE2, TE3 modes. The last three convert the TM0 to the TM1, TM2, and TM3 modes.

The coupling length of each coupler needs to be optimized for the best efficiency coupling. This can be done by performing a parameter scan over the coupling length. Parameter scans have been demonstrated in various examples such as the MMI power splitter and the parameter scan tutorial. For the sake of simplicity, we only perform simulations on the optimized parameter values reported in the referenced literature.

Switching the logging level back to "WARNING" so we can catch any helpful warnings.

[12]:

td.config.logging_level = "WARNING"

Infrastructure Setup#

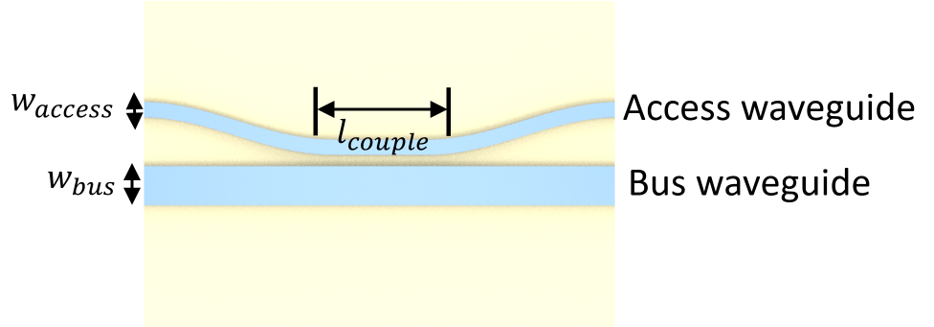

The asymmetric directional coupler consists of an access waveguide and a bus waveguide. The bending part is given by a cosine function. The horizontal and vertical lengths of the waveguide bend are fixed to be \(B_x = 10 \mu m\) \(B_y = 1 \mu m\). This ensures the loss at the bend is small.

[13]:

Bx = 10 # horizontal length of the waveguide bend

By = 1 # verticel length of the waveguide bend

We define a function to construct the entire directional coupler simulation. This function will be used repeatedly to simulate six directional couplers. Within this function, we use gdstk to construct the structures.

[14]:

def make_sim(pol, w_access, w_bus, gap, l_couple):

# construct the access waveguide including the bends

y = By + (w_access + w_bus) / 2 + gap

access_wg = gdstk.RobustPath(

(-3 * l_couple, y), w_access, simple_path=True, layer=1, datatype=0

)

access_wg.segment((-l_couple / 2 - Bx, y))

access_wg.segment(

(-l_couple / 2, y), offset=lambda u: (np.cos(u * np.pi) - 1) * By / 2

)

access_wg.segment((l_couple / 2, y))

access_wg.segment(

(l_couple / 2 + Bx, y), offset=lambda u: (np.cos((1 - u) * np.pi) - 1) * By / 2

)

access_wg.segment((3 * l_couple, y))

# construct the bus waveguide

bus_wg = gdstk.FlexPath(

[(-3 * l_couple, 0), (3 * l_couple, 0)], w_bus, layer=1, datatype=1

)

# define a cell

cell = gdstk.Cell("directional_coupler")

cell.add(access_wg)

cell.add(bus_wg)

# construct a list of polyslab from the cell

DC = td.PolySlab.from_gds(

cell,

gds_layer=1,

axis=2,

slab_bounds=(-h / 2, h / 2),

)

# define access waveguide and bus waveguide structures

access_wg = td.Structure(geometry=DC[0], medium=si)

bus_wg = td.Structure(geometry=DC[1], medium=si)

# y coordinate of the access waveguide input

y_in = (w_access + w_bus) / 2 + gap + By

# simulation domain size

Lx = l_couple + 2 * Bx + lda0

Ly = 2 * (y_in + lda0)

Lz = 10 * h

sim_size = (Lx, Ly, Lz)

# symmetry for each polarization

if pol == "TE":

symmetry = symmetry = (0, 0, 1)

elif pol == "TM":

symmetry = symmetry = (0, 0, -1)

else:

symmetry = symmetry = (0, 0, 0)

# define a mode source to lauch either te0 or tm0 mode to the access waveguide

mode_source = td.ModeSource(

center=(-Lx / 2 + lda0 / 2, y_in, 0),

size=(0, 6 * w_access, 8 * h),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=td.ModeSpec(num_modes=1, target_neff=n_si),

mode_index=0,

)

# define a flux monitor to measure the transmission to the bus waveguide

bus_flux_monitor = td.FluxMonitor(

center=(Lx / 2 - lda0 / 2, 0, 0),

size=(0, 2 * w_bus, 6 * h),

freqs=freqs,

name="bus_flux",

)

# define a field monitor to visualize the field distribution in the xy plane

field_monitor = td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

# define a mode monitor to check the mode composition at the bus waveguide

bus_mode_monitor = td.ModeMonitor(

center=(Lx / 2 - lda0 / 2, 0, 0),

size=(0, 2 * w_bus, 6 * h),

freqs=freqs,

mode_spec=td.ModeSpec(num_modes=4, target_neff=n_si),

name="bus_mode",

)

run_time = 2e-12 # simulation run time

# define simulation

sim = td.Simulation(

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=15, wavelength=lda0),

structures=[access_wg, bus_wg],

sources=[mode_source],

monitors=[bus_flux_monitor, field_monitor, bus_mode_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(

boundary=td.PML()

), # pml is applied to all boundaries

medium=sio2, # the background medium is set to sio2 to model the substrate and top cladding

symmetry=symmetry,

)

return sim

Lastly, we create a dictionary to store the optimized design parameters. The values are taken from the reference.

[15]:

design_params = {

"TM1": {"w_access": 0.4, "w_bus": 1.035, "gap": 0.3, "l_couple": 4.6},

"TM2": {"w_access": 0.4, "w_bus": 1.695, "gap": 0.3, "l_couple": 6.8},

"TM3": {"w_access": 0.4, "w_bus": 2.363, "gap": 0.3, "l_couple": 9},

"TE1": {"w_access": 0.4, "w_bus": 0.835, "gap": 0.2, "l_couple": 15.5},

"TE2": {"w_access": 0.406, "w_bus": 1.29, "gap": 0.2, "l_couple": 21.3},

"TE3": {"w_access": 0.379, "w_bus": 1.631, "gap": 0.2, "l_couple": 17.6},

}

TE0 to TE3 Convertion#

With the infrastructure setup above, we are ready to perform simulations for the six directional couplers. First, we model the TE0 to TE3 coupler.

Simulation Setup#

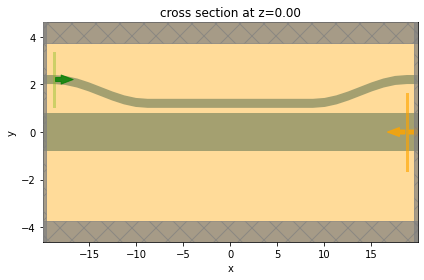

We use the make_sim function to define the simulation given the access waveguide width, the bus waveguide width, the coupling regime length, and the polarization. Using the plot function, we can visualize the simulation setup.

[16]:

sim = make_sim("TE", **design_params["TE3"])

ax = sim.plot(z=0)

ax.set_aspect("auto")

Before submitting the simulation job to the server, we can use the ModeSolver again to visualize the first four TE modes supported in the bus waveguide.

[17]:

# define mode solver

mode_solver = ModeSolver(

simulation=sim,

plane=td.Box(

center=sim.monitors[0].center,

size=sim.monitors[0].size,

),

mode_spec=td.ModeSpec(num_modes=4, target_neff=n_si),

freqs=[freq0],

)

mode_data = mode_solver.solve()

mode_data.to_dataframe()

[17]:

| wavelength | n eff | k eff | TE (Ey) fraction | wg TE fraction | wg TM fraction | mode area | ||

|---|---|---|---|---|---|---|---|---|

| f | mode_index | |||||||

| 1.934145e+14 | 0 | 1.55 | 2.905346 | 0.0 | 0.999784 | 0.975445 | 0.815301 | 0.361678 |

| 1 | 1.55 | 2.793373 | 0.0 | 0.998957 | 0.902743 | 0.826557 | 0.406816 | |

| 2 | 1.55 | 2.597596 | 0.0 | 0.996677 | 0.785704 | 0.845725 | 0.485229 | |

| 3 | 1.55 | 2.300998 | 0.0 | 0.989402 | 0.635668 | 0.873389 | 0.583472 |

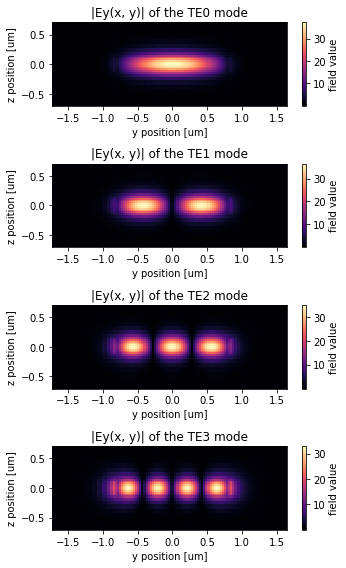

For the TE modes, the dominant electric field is in the \(y\) direction. Here we visualize \(E_y\) for the four modes.

[18]:

mode_indices = [0, 1, 2, 3]

f, ax = plt.subplots(4, 1, tight_layout=True, figsize=(5, 8))

for i, mode_index in enumerate(mode_indices):

abs(mode_data.Ey.isel(mode_index=mode_index)).plot(

x="y", y="z", ax=ax[i], cmap="magma"

)

ax[i].set_title(f"|Ey(x, y)| of the TE{i} mode")

Submit the simulation job to the server.

[19]:

job = web.Job(simulation=sim, task_name="evanescent_coupler_te3", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:37:24 PST Created task 'evanescent_coupler_te3' with task_id 'fdve-c2ad32ad-760d-4e6c-8004-0081a9dc4019' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-c2ad32ad-760d-4e6c-8004-0081a9dc4019'.

15:37:25 PST status = queued

15:37:41 PST status = preprocess

15:38:01 PST Maximum FlexCredit cost: 0.099. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:39:58 PST early shutoff detected at 64%, exiting.

status = postprocess

15:40:08 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-c2ad32ad-760d-4e6c-8004-0081a9dc4019'.

15:40:10 PST loading simulation from data/simulation_data.hdf5

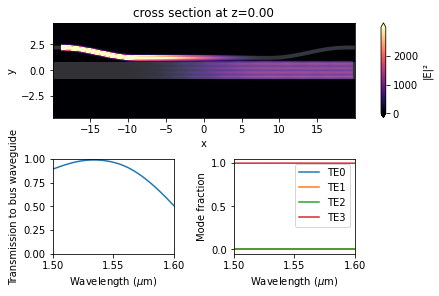

Postprocessing and Visualization#

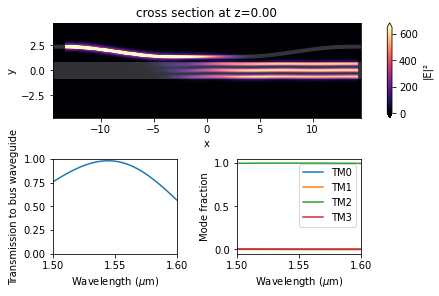

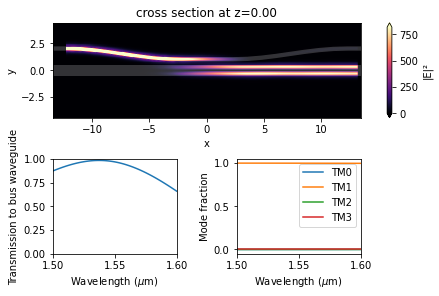

After the simulation is complete, we can visualize the field intensity distribution, the transmission to the bus waveguide, and the mode composition at the bus waveguide. Since similar postprocessing and visualization will be performed for other directional couplers, we define a function here.

[20]:

def postprocess(sim_data, pol):

fig = plt.figure(constrained_layout=True)

gs = GridSpec(2, 2, figure=fig)

ax1 = fig.add_subplot(gs[0, :])

ax2 = fig.add_subplot(gs[1, 0])

ax3 = fig.add_subplot(gs[1, 1])

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", f=freq0, ax=ax1

)

ax1.set_aspect("auto")

T_bus = sim_data["bus_flux"].flux

ax2.plot(ldas, T_bus)

ax2.set_xlim(1.5, 1.6)

ax2.set_ylim(0, 1)

ax2.set_xlabel("Wavelength ($\mu$m)")

ax2.set_ylabel("Transmission to bus waveguide")

mode_amp = sim_data["bus_mode"].amps.sel(direction="+")

mode_power = np.abs(mode_amp) ** 2 / T_bus

ax3.plot(ldas, mode_power)

ax3.set_xlim(1.5, 1.6)

ax3.set_xlabel("Wavelength ($\mu$m)")

ax3.set_ylabel("Mode fraction")

ax3.legend((f"{pol}0", f"{pol}1", f"{pol}2", f"{pol}3"))

From the field intensity distribution, we can see an efficient conversion of the TE0 mode at the access waveguide to the TE3 mode at the bus waveguide. The transmission spectrum also confirms a high transmission around 95% at 1550 nm. The mode composition shows a nearly pure TE3 mode at the bus waveguide.

[21]:

postprocess(sim_data, "TE")

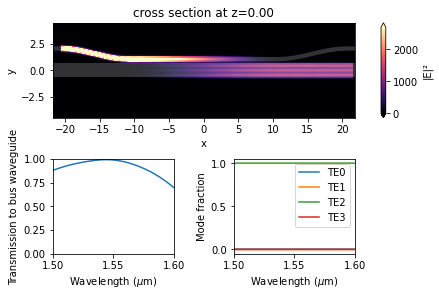

TE0 to TE2 Convertion#

We repeat the above process for the TEO to TE2 coupler as well as the other four couplers.

[22]:

sim = make_sim("TE", **design_params["TE2"])

job = web.Job(simulation=sim, task_name="evanescent_coupler_te2", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:40:12 PST Created task 'evanescent_coupler_te2' with task_id 'fdve-cb6ed894-e246-441b-9068-fe5917001ba1' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-cb6ed894-e246-441b-9068-fe5917001ba1'.

15:40:13 PST status = queued

15:40:23 PST status = preprocess

15:40:29 PST Maximum FlexCredit cost: 0.102. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:41:21 PST early shutoff detected at 68%, exiting.

status = postprocess

15:41:34 PST status = success

15:41:35 PST View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-cb6ed894-e246-441b-9068-fe5917001ba1'.

15:41:37 PST loading simulation from data/simulation_data.hdf5

[23]:

postprocess(sim_data, "TE")

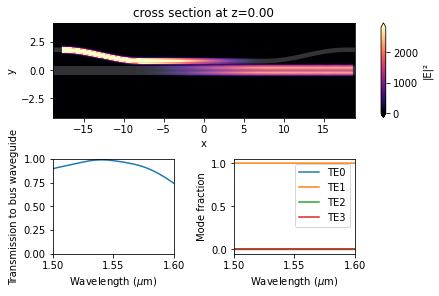

TE0 to TE1 Convertion#

[24]:

sim = make_sim("TE", **design_params["TE1"])

job = web.Job(simulation=sim, task_name="evanescent_coupler_te1", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:41:39 PST Created task 'evanescent_coupler_te1' with task_id 'fdve-f6bef763-1d3a-4283-bbe4-40a1000f55a4' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-f6bef763-1d3a-4283-bbe4-40a1000f55a4'.

15:41:40 PST status = queued

15:41:49 PST status = preprocess

15:41:55 PST Maximum FlexCredit cost: 0.081. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

15:41:56 PST running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:42:38 PST early shutoff detected at 60%, exiting.

15:42:39 PST status = postprocess

15:42:48 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-f6bef763-1d3a-4283-bbe4-40a1000f55a4'.

15:42:49 PST loading simulation from data/simulation_data.hdf5

[25]:

postprocess(sim_data, "TE")

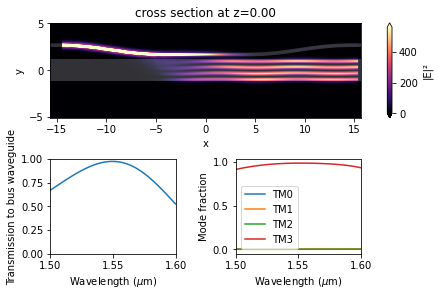

TM0 to TM3 Convertion#

[26]:

sim = make_sim("TM", **design_params["TM3"])

job = web.Job(simulation=sim, task_name="evanescent_coupler_tm3", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:42:51 PST Created task 'evanescent_coupler_tm3' with task_id 'fdve-a69141ca-3ae2-40dd-8aa9-ca656fc9becc' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-a69141ca-3ae2-40dd-8aa9-ca656fc9becc'.

15:42:52 PST status = queued

15:43:14 PST status = preprocess

15:43:20 PST Maximum FlexCredit cost: 0.087. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:43:48 PST early shutoff detected at 32%, exiting.

status = postprocess

15:44:08 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-a69141ca-3ae2-40dd-8aa9-ca656fc9becc'.

15:44:09 PST loading simulation from data/simulation_data.hdf5

[27]:

postprocess(sim_data, "TM")

TM0 to TM2 Convertion#

[28]:

sim = make_sim("TM", **design_params["TM2"])

job = web.Job(simulation=sim, task_name="evanescent_coupler_tm2", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:44:18 PST Created task 'evanescent_coupler_tm2' with task_id 'fdve-820a21f1-863a-42a9-be53-0a45896c43f8' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-820a21f1-863a-42a9-be53-0a45896c43f8'.

15:44:19 PST status = queued

15:44:32 PST status = preprocess

15:44:40 PST Maximum FlexCredit cost: 0.073. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:45:06 PST early shutoff detected at 32%, exiting.

status = postprocess

15:45:17 PST status = success

15:45:18 PST View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-820a21f1-863a-42a9-be53-0a45896c43f8'.

15:45:19 PST loading simulation from data/simulation_data.hdf5

[29]:

postprocess(sim_data, "TM")

TM0 to TM1 Convertion#

[30]:

sim = make_sim("TM", **design_params["TM1"])

job = web.Job(simulation=sim, task_name="evanescent_coupler_tm1", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:45:21 PST Created task 'evanescent_coupler_tm1' with task_id 'fdve-b6a1c166-1bea-4210-b5a3-6cc0b824be07' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-b6a1c166-1bea-4210-b5a3-6cc0b824be07'.

15:45:22 PST status = queued

15:45:30 PST status = preprocess

15:45:36 PST Maximum FlexCredit cost: 0.060. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:46:24 PST early shutoff detected at 28%, exiting.

status = postprocess

15:46:37 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-b6a1c166-1bea-4210-b5a3-6cc0b824be07'.

15:46:38 PST loading simulation from data/simulation_data.hdf5

[31]:

postprocess(sim_data, "TM")

8-channel (De)multiplexer Simulation#

Once we confirm the efficiency of the six couplers individually, we are ready to put them together to construct the entire (de)multiplexer device. This device is made by connecting the couplers via linear tapers. The linear tapers have a small angle of 1.8 degree to ensure good transmission. The overall device has a length of about 200 \(\mu m\).

The process of creating the structure is rather long and tedious. Therefore, we will skip that in this notebook and only import the constructed GDSII file. The GDSII file can be downloaded from our documentation repo if needed.

There are eight input ports labeled as I1, I2, …, I8. The top four ports are for TE0 excitation. The bottom four ports are for TM0 excitation.

[32]:

gds_path = "misc/8ChannelDemultiplexer.gds" # path of the gds file

lib = gdstk.read_gds(infile=gds_path) # import gds file

cell = lib.cells[0] # read cell

Similar to what is demonstrated above, we will define a list of PolySlabs from the cell.

[33]:

demultiplexer_poly = td.PolySlab.from_gds(

cell,

gds_layer=0,

axis=2,

slab_bounds=(-h / 2, h / 2),

)

Convert the list of PolySlabs to a list of Tidy3D Structures.

[34]:

demultiplexer_structure = []

for s in demultiplexer_poly:

demultiplexer_structure.append(

td.Structure(

geometry=s,

medium=si,

)

)

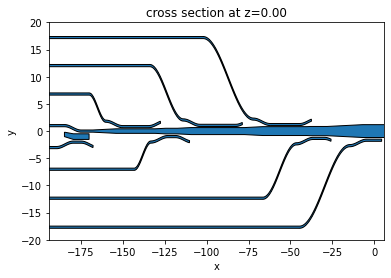

To confirm the structures are defined correctly, we can visualize them. Since this device has a large aspect ratio (~200 \(\mu m\) in length and ~35 \(\mu m\) in width), we will set the aspect ratio of the plot to auto. Otherwise, the details of the structures are not clearly viewed.

[35]:

f, ax = plt.subplots(1, 1)

for s in demultiplexer_structure:

s.plot(z=0, ax=ax)

ax.set_ylim(-20, 20)

ax.set_xlim(-194, 6)

ax.set_aspect("auto")

Now we are ready to perform simulation on this device. To fully characterize the device, we need to excite all eight inputs individually and obtain the transmission at the end of the central bus waveguide. However, since the model is pretty large, for the sake of not making the notebook too long, we will only select two inputs in this notebook as demonstrations.

First, let’s excite the I7 port with the TM0 mode, which should be converted to TM2 mode in the bus waveguide.

[36]:

# define a mode source at the straight part of the I7 port

mode_source = td.ModeSource(

center=(-75, -12.5, 0),

size=(0, 2.5, 8 * h),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=td.ModeSpec(num_modes=1, target_neff=n_si),

mode_index=0,

)

# define a mode monitor at the end of the bus waveguide to measure coupling efficiency

bus_mode_monitor = td.ModeMonitor(

center=(6, 0, 0),

size=(0, 4, 8 * h),

freqs=freqs,

mode_spec=td.ModeSpec(num_modes=4, target_neff=n_si),

name="bus_mode",

)

# define a field monitor at the xy plane to visualize field distribution

field_monitor = td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

run_time = 5e-12 # simulation run time

# define simulation

sim = td.Simulation(

size=(200, 20, 10 * h),

center=(-94, -5, 0),

grid_spec=td.GridSpec.auto(min_steps_per_wvl=15, wavelength=lda0),

structures=demultiplexer_structure,

sources=[mode_source],

monitors=[bus_mode_monitor, field_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

symmetry=(0, 0, -1),

)

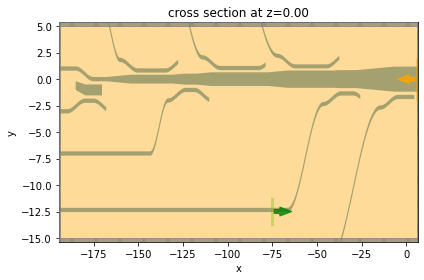

Since this simulation is computationally heavy, it is always a good practice to visualize the simulation setup first before submitting the job to the server. This helps avoid running incorrectly set up simulations and wasting time and FlexCredit.

[37]:

ax = sim.plot(z=0)

ax.set_aspect("auto")

Submit the simulation job to the server. Before running the simulation, we can get a cost estimation using estimate_cost. This prevents us from accidentally running large jobs that we set up by mistake. The estimated cost is the maximum cost corresponding to running all the time steps.

[38]:

job = web.Job(simulation=sim, task_name="8_channel_demultiplexer_I7", verbose=True)

estimated_cost = web.estimate_cost(job.task_id)

15:46:41 PST Created task '8_channel_demultiplexer_I7' with task_id 'fdve-eac46902-875a-425a-8e98-e3106b6e987c' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-eac46902-875a-425a-8e98-e3106b6e987c'.

15:46:46 PST Maximum FlexCredit cost: 4.293. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

[39]:

sim_data = job.run(path="data/simulation_data.hdf5")

15:46:47 PST status = queued

15:46:56 PST status = preprocess

15:47:02 PST Maximum FlexCredit cost: 4.293. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:50:17 PST early shutoff detected at 64%, exiting.

status = postprocess

15:50:28 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-eac46902-875a-425a-8e98-e3106b6e987c'.

15:50:37 PST loading simulation from data/simulation_data.hdf5

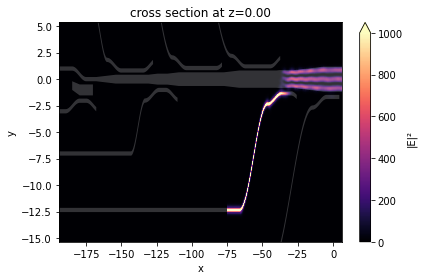

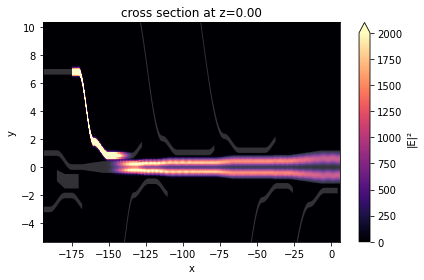

The visualization process is similar to what we did in the previous section. First, inspect the field intensity distribution. This shows that the TM0 mode is indeed converted to the TM2 mode in the bus waveguide.

Noticeably, there appears to be some leakage at the waveguide bends. This leaves room for further optimization. It can be improved by using a smoother transition such as a Euler bend.

[40]:

ax = sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", f=freq0, vmin=0, vmax=1000

)

ax.set_aspect("auto")

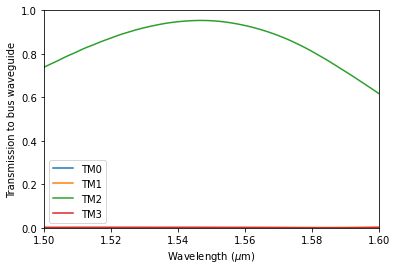

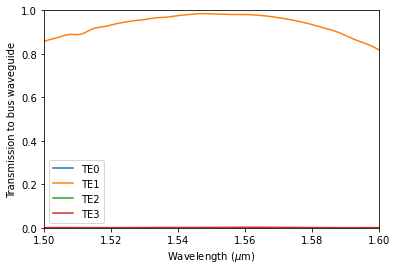

Despite the loss at the waveguide bend, the coupling efficiency to TM2 mode is still about 95%.

[41]:

for index in range(4):

amp = sim_data["bus_mode"].amps.sel(mode_index=index, direction="+")

T = np.abs(amp)**2

plt.plot(ldas, T, label=f'TM{index}')

plt.xlim(1.5, 1.6)

plt.ylim(0, 1)

plt.xlabel("Wavelength ($\mu$m)")

plt.ylabel("Transmission to bus waveguide")

plt.legend()

plt.show()

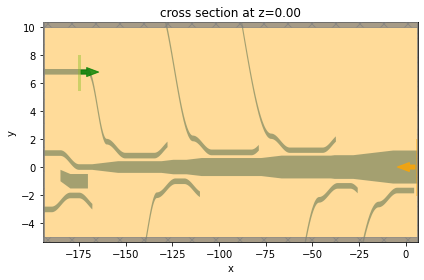

Lastly, we perform a simulation by exciting the I3 port with the TE0 mode. For this simulation, we only need to update a few things from the previous simulation.

[42]:

# define a mode source at the I3 port

mode_source = td.ModeSource(

center=(-175, 6.8, 0),

size=(0, 2.5, 8 * h),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=td.ModeSpec(num_modes=1, target_neff=n_si),

mode_index=0,

)

# define a simulation by copying the previous simulation and updating a few things

sim = sim.copy(update={

'size':(200, 15, 10 * h),

'center':(-94, 2.5, 0),

'symmetry':(0, 0, 1),

'sources':[mode_source],

})

ax = sim.plot(z=0)

ax.set_aspect("auto")

[43]:

job = web.Job(simulation=sim, task_name="8_channel_demultiplexer_I3", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

15:50:48 PST Created task '8_channel_demultiplexer_I3' with task_id 'fdve-b5fd60de-f84b-4595-ac21-45ab0f3b4e30' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-b5fd60de-f84b-4595-ac21-45ab0f3b4e30'.

15:50:49 PST status = queued

15:51:08 PST status = preprocess

15:51:13 PST Maximum FlexCredit cost: 3.300. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

16:01:31 PST early shutoff detected at 76%, exiting.

status = postprocess

16:01:41 PST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbenc h?taskId=fdve-b5fd60de-f84b-4595-ac21-45ab0f3b4e30'.

16:01:47 PST loading simulation from data/simulation_data.hdf5

Field distribution shows a good conversion to the TE1 mode. Loss at the waveguide bend also appears to be smaller in this case.

[44]:

ax = sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", f=freq0, vmin=0, vmax=2000

)

ax.set_aspect("auto")

Nearly 100% coupling efficiency is achieved.

[45]:

for index in range(4):

amp = sim_data["bus_mode"].amps.sel(mode_index=index, direction="+")

T = np.abs(amp)**2

plt.plot(ldas, T, label=f'TE{index}')

plt.xlim(1.5, 1.6)

plt.ylim(0, 1)

plt.xlabel("Wavelength ($\mu$m)")

plt.ylabel("Transmission to bus waveguide")

plt.legend()

plt.show()

Besides I3 and I7, other input ports can also be examined systematically, which we do not explicitly shown in this notebook.

[ ]: