Inverse design optimization of a compact grating coupler#

To install the

jaxmodule required for this feature, we recommend runningpip install "tidy3d[jax]".

This notebook contains a long optimization. Running the entire notebook will cost about 10 FlexCredits and take a few hours.

The ability to couple light in and out of photonic integrated circuits (PICs) is crucial for developing wafer-scale systems and tests. This need makes designing efficient and compact grating couplers an important task in the PIC development cycle. In this notebook, we will demonstrate how to use Tidy3D’s adjoint plugin to perform the inverse design of a compact 3D grating coupler. We will show how to improve design fabricability by enhancing permittivity binarization and controlling the device’s minimum feature size.

In addition, if you are interested in more conventional designs, we modeled an uniform grating coupler and a Focusing apodized grating coupler in previous case studies. For more integrated photonic examples, please visit our examples page. If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials. FDTD simulations can diverge due to various reasons. If you run into any simulation divergence issues, please follow the steps outlined in our troubleshooting guide to resolve it.

We start by importing our typical python packages, jax, tidy3d and its adjoint plugin.

[1]:

# Standard python imports.

from typing import List

import numpy as np

import scipy as sp

import matplotlib.pylab as plt

import os

import json

import pydantic as pd

from typing import Callable

# Import jax to be able to use automatic differentiation.

import jax.numpy as jnp

import jax.scipy as jsp

from jax import value_and_grad

# Import regular tidy3d.

import tidy3d as td

import tidy3d.web as web

# Import the components we need from the adjoint plugin.

from tidy3d.plugins.adjoint import (

JaxSimulation,

JaxBox,

JaxCustomMedium,

JaxStructure,

JaxSimulationData,

JaxDataArray,

JaxPermittivityDataset,

)

from tidy3d.plugins.adjoint.web import run

Grating Coupler Inverse Design Configuration#

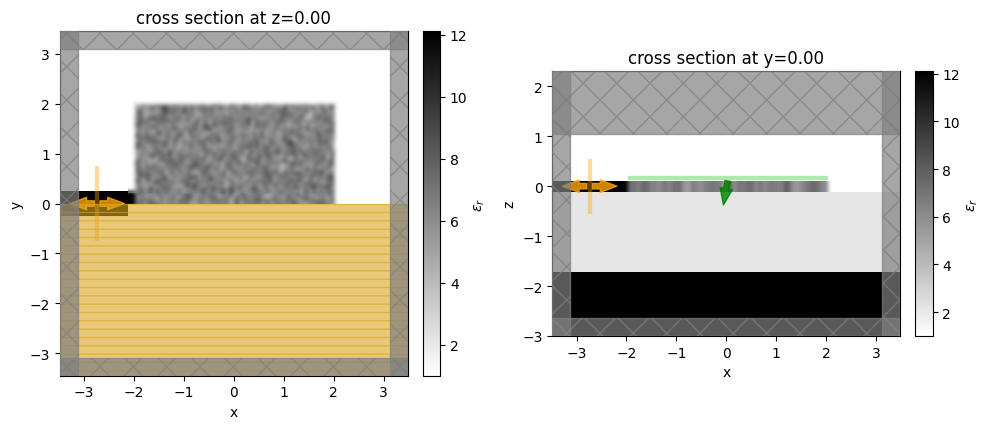

The grating coupler inverse design begins with a rectangular design region connected to a \(Si\) waveguide. Throughout the optimization process, this initial structure evolves to convert a vertically incident Gaussian-like mode from an optical fiber into a guided mode and then funnel it into the \(Si\) waveguide.

We are considering a full-etched grating structure, so a \(SiO_{2}\) BOX layer is included. To reduce backreflection, we adjusted the fiber tilt angle to \(10^{\circ}\) [1, 2].

In the following block of code, you can find the parameters that can be modified to configure the grating coupler structure, optimization, and simulation setup. Special care should be devoted to the it_per_step and opt_steps variables bellow.

[2]:

# Geometric parameters.

w_thick = 0.22 # Waveguide thickness (um).

w_width = 0.5 # Waveguide width (um).

w_length = 1.0 # Waveguide length (um).

box_thick = 1.6 # SiO2 BOX thickness (um).

spot_size = 2.5 # Spot size of the input Gaussian field regarding a lensed fiber (um).

fiber_tilt = 10.0 # Fiber tilt angle (degrees).

src_offset = 0.05 # Distance between the source focus and device (um).

# Material.

nSi = 3.48 # Silicon refractive index.

nSiO2 = 1.44 # Silica refractive index.

# Design region parameters.

gc_width = 4.0 # Grating coupler width (um).

gc_length = 4.0 # Grating coupler length (um).

dr_grid_size = 0.02 # Grid size within the design region (um).

# Inverse design set up parameters.

#################################################################

# Total number of iterations = opt_steps x it_per_step.

it_per_step = 1 # Number of iterations per optimization step.

opt_steps = 75 # Number of optimization steps.

#################################################################

eta = 0.50 # Threshold value for the projection filter.

fom_name = "fom_field" # Name of the monitor used to compute the objective function.

# Simulation wavelength.

wl = 1.55 # Central simulation wavelength (um).

bw = 0.06 # Simulation bandwidth (um).

n_wl = 61 # Number of wavelength points within the bandwidth.

# feature size

min_feature_size = 0.080

filter_radius = min_feature_size

# Buffer layer thickness

border_buffer = 0.16

# projection

beta_min = 1.0

beta_max = 30.0

[3]:

total_iter = opt_steps * it_per_step

print(f"Total iterations = {total_iter}")

Total iterations = 75

Inverse Design Optimization Set Up#

We will calculate the values of some parameters used throughout the inverse design set up.

[4]:

# Minimum and maximum values for the permittivities.

eps_max = nSi**2

eps_min = 1.0

# Material definitions.

mat_si = td.Medium(permittivity=eps_max) # Waveguide material.

mat_sio2 = td.Medium(permittivity=nSiO2**2) # Substrate material.

# Wavelengths and frequencies.

wl_max = wl + bw / 2

wl_min = wl - bw / 2

wl_range = np.linspace(wl_min, wl_max, n_wl)

freq = td.C_0 / wl

freqs = td.C_0 / wl_range

freqw = 0.5 * (freqs[0] - freqs[-1])

run_time = 5e-12

# Computational domain size.

pml_spacing = 0.6 * wl

size_x = pml_spacing + w_length + gc_length + 2 * border_buffer

size_y = gc_width + 2 * pml_spacing + 2 * border_buffer

size_z = w_thick + box_thick + 2 * pml_spacing

center_z = size_z / 2 - pml_spacing - w_thick / 2

eff_inf = 1000

# Inverse design variables.

src_pos_z = w_thick / 2 + src_offset

mon_pos_x = -size_x / 2 + 0.25 * wl

mon_w = int(3 * w_width / dr_grid_size) * dr_grid_size

mon_h = int(5 * w_thick / dr_grid_size) * dr_grid_size

nx = int((gc_length + 2 * border_buffer) / dr_grid_size)

ny = int((gc_width + 2 * border_buffer) / dr_grid_size / 2.0)

npar = int(nx * ny)

dr_size_x = nx * dr_grid_size

dr_size_y = 2 * ny * dr_grid_size

dr_center_x = -size_x / 2 + w_length + dr_size_x / 2

n_border = int(border_buffer / dr_grid_size)

First, we will introduce the simulation components that do not change during optimization, such as the \(Si\) waveguide and \(SiO_{2}\) BOX layer. Additionally, we will include a Gaussian source to drive the simulations, and a mode monitor to compute the objective function.

[5]:

# Input/output waveguide.

waveguide = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -w_width / 2, -w_thick / 2),

rmax=(-size_x / 2 + w_length, w_width / 2, w_thick / 2),

),

medium=mat_si,

)

# SiO2 BOX layer.

sio2_substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, -w_thick / 2 - box_thick),

rmax=(eff_inf, eff_inf, -w_thick / 2),

),

medium=mat_sio2,

)

# Si substrate.

si_substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, -eff_inf),

rmax=(eff_inf, eff_inf, -w_thick / 2 - box_thick),

),

medium=mat_si,

)

# Gaussian source focused above the grating coupler.

gauss_source = td.GaussianBeam(

center=(dr_center_x, 0, src_pos_z),

size=(dr_size_x - 2 * border_buffer, dr_size_y - 2 * border_buffer, 0),

source_time=td.GaussianPulse(freq0=freq, fwidth=freqw),

pol_angle=np.pi / 2,

angle_theta=fiber_tilt * np.pi / 180.0,

direction="-",

num_freqs=7,

waist_radius=spot_size / 2,

)

# Monitor where we will compute the objective function from.

mode_spec = td.ModeSpec(num_modes=1, target_neff=nSi)

fom_monitor = td.ModeMonitor(

center=[mon_pos_x, 0, 0],

size=[0, mon_w, mon_h],

freqs=[freq],

mode_spec=mode_spec,

name=fom_name,

)

Now, we will define a random vector of initial design parameters or load a previously designed structure.

Note: if a previous optimization file is found, the optimizer will pick up where that left off instead.

[6]:

init_par = np.random.uniform(0, 1, int(npar))

init_par = sp.ndimage.gaussian_filter(init_par, 1)

init_par = init_par.reshape((nx, ny))

Fabrication Constraints#

We will use jax to build functions that improve device fabricability. A classical conic density filter, which is popular in topology optimization problems, is used to enforce a minimum feature size specified by the filter_radius variable. Next, a hyperbolic tangent projection function is applied to eliminate grayscale and obtain a binarized permittivity pattern. The beta parameter controls the sharpness of the transition in the projection function, and for better results, this

parameter should be gradually increased throughout the optimization process. Finally, the design parameters are transformed into permittivity values. For a detailed review of these methods, refer to [3].

We will also introduce a buffer layer around the design region to enhance fabricability at the interfaces. The permittivity is enforced to lower values within the buffer layer, except at the output waveguide connection where we want a smooth transition.

[7]:

from tidy3d.plugins.adjoint.utils.filter import ConicFilter, BinaryProjector

conic_filter = ConicFilter(radius=filter_radius, design_region_dl=dr_grid_size)

def tanh_projection(x, beta, eta=0.5):

tanhbn = jnp.tanh(beta * eta)

num = tanhbn + jnp.tanh(beta * (x - eta))

den = tanhbn + jnp.tanh(beta * (1 - eta))

return num / den

def filter_project(x, beta, eta=0.5):

x = conic_filter.evaluate(x)

return tanh_projection(x, beta=beta, eta=eta)

def interface_buffer(params):

"""Introduce a buffer around design to enhance fabricability at the interfaces."""

par = jnp.asarray(params)

par = par.at[0:n_border, :].set(0)

par = par.at[nx - n_border :, :].set(0)

par = par.at[:, ny - n_border :].set(0)

par = par.at[0:n_border, 0 : int((w_width / 2) / dr_grid_size) + 1].set(1)

return par

def pre_process(params, beta):

"""Get the permittivity values (1, eps_wg) array as a funciton of the parameters (0,1)"""

params1 = interface_buffer(params)

params2 = filter_project(params1, beta=beta)

params3 = filter_project(params2, beta=beta)

return params3

def get_eps_values(params, beta):

params = pre_process(params, beta=beta)

eps_values = eps_min + (eps_max - eps_min) * params

return eps_values

[8]:

def get_eps(design_param, beta: float = 1.00, binarize: bool = False) -> np.ndarray:

"""Returns the permittivities after applying a conic density filter on design parameters

to enforce fabrication constraints, followed by a binarization projection function

which reduces grayscale.

Parameters:

design_param: np.ndarray

Vector of design parameters.

beta: float = 1.0

Sharpness parameter for the projection filter.

binarize: bool = False

Enforce binarization.

Returns:

eps: np.ndarray

Permittivity vector.

"""

# Calculates the permittivities from the transformed design parameters.

eps = get_eps_values(design_param, beta=beta)

if binarize:

eps = jnp.where(eps < (eps_min + eps_max) / 2, eps_min, eps_max)

else:

eps = jnp.where(eps < eps_min, eps_min, eps)

eps = jnp.where(eps > eps_max, eps_max, eps)

return eps

The permittivity values obtained from the design parameters are then used to build a JaxCustomMedium. As we will consider symmetry about the x-axis in the simulations, only the upper-half part of the design region needs to be populated. A JaxStructure built using the JaxCustomMedium will be returned by the following function:

[9]:

def update_design(eps, unfold: bool = False) -> List[JaxStructure]:

# Reflects the structure about the x-axis.

nyii = ny

y_min = 0

dr_s_y = dr_size_y / 2

dr_c_y = dr_s_y / 2

eps_val = jnp.array(eps).reshape((nx, ny, 1, 1))

if unfold:

nyii = 2 * ny

y_min = -dr_size_y / 2

dr_s_y = dr_size_y

dr_c_y = 0

eps_val = np.concatenate((np.fliplr(np.copy(eps_val)), eps_val), axis=1)

# Definition of the coordinates x,y along the design region.

coords_x = [(dr_center_x - dr_size_x / 2) + ix * dr_grid_size for ix in range(nx)]

coords_y = [y_min + iy * dr_grid_size for iy in range(nyii)]

coords = dict(x=coords_x, y=coords_y, z=[0], f=[freq])

# Creation of a custom medium using the values of the design parameters.

eps_components = {

f"eps_{dim}{dim}": JaxDataArray(values=eps_val, coords=coords) for dim in "xyz"

}

eps_dataset = JaxPermittivityDataset(**eps_components)

eps_medium = JaxCustomMedium(eps_dataset=eps_dataset)

box = JaxBox(center=(dr_center_x, dr_c_y, 0), size=(dr_size_x, dr_s_y, w_thick))

design_structure = JaxStructure(geometry=box, medium=eps_medium)

return [design_structure]

Next, we will write a function to return the JaxSimulation object. Note that we are using a MeshOverrideStructure to obtain a uniform mesh over the design region.

[10]:

def make_adjoint_sim(

design_param, beta: float = 1.00, unfold: bool = False, binarize: bool = False

) -> JaxSimulation:

# Builds the design region from the design parameters.

eps = get_eps(design_param, beta, binarize)

design_structure = update_design(eps, unfold=unfold)

# Creates a uniform mesh for the design region.

adjoint_dr_mesh = td.MeshOverrideStructure(

geometry=td.Box(

center=(dr_center_x, 0, 0), size=(dr_size_x, dr_size_y, w_thick)

),

dl=[dr_grid_size, dr_grid_size, dr_grid_size],

enforce=True,

)

return JaxSimulation(

size=[size_x, size_y, size_z],

center=[0, 0, -center_z],

grid_spec=td.GridSpec.auto(

wavelength=wl_max,

min_steps_per_wvl=15,

override_structures=[adjoint_dr_mesh],

),

symmetry=(0, -1, 0),

structures=[waveguide, sio2_substrate, si_substrate],

input_structures=design_structure,

sources=[gauss_source],

monitors=[],

output_monitors=[fom_monitor],

run_time=run_time,

subpixel=True,

)

Let’s visualize the simulation set up and verify if all the elements are in their correct places.

[11]:

init_design = make_adjoint_sim(init_par, beta=beta_min)

fig, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 10))

init_design.plot_eps(z=0, ax=ax1)

init_design.plot_eps(y=0, ax=ax2)

plt.show()

WARNING:jax._src.xla_bridge:An NVIDIA GPU may be present on this machine, but a CUDA-enabled jaxlib is not installed. Falling back to cpu.

Optimization#

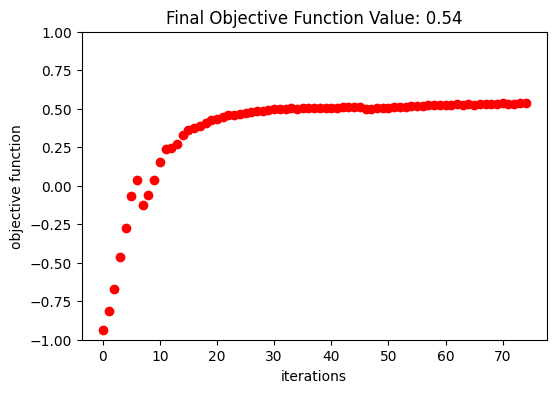

We need to provide an objective function and its gradients with respect to the design parameters of the optimization algorithm.

Our figure-of-merit (FOM) is the coupling efficiency of the incident power into the fundamental transverse electric mode of the \(Si\) waveguide. The optimization algorithm will call the objective function at each iteration step. Therefore, the objective function will create the adjoint simulation, run it, and return the FOM value.

[12]:

# Figure of Merit (FOM) calculation.

def fom(sim_data: JaxSimulationData) -> float:

"""Return the power at the mode index of interest."""

output_amps = sim_data.output_data[0].amps

amp = output_amps.sel(direction="-", f=freq, mode_index=0)

return jnp.sum(jnp.abs(amp) ** 2)

def penalty(params, beta, delta_eps=0.49):

params = pre_process(params, beta=beta)

dilate_fn = lambda x: filter_project(x, beta=100, eta=0.5 - delta_eps)

eroded_fn = lambda x: filter_project(x, beta=100, eta=0.5 + delta_eps)

params_dilate_erode = eroded_fn(dilate_fn(params))

params_erode_dilate = dilate_fn(eroded_fn(params))

diff = params_dilate_erode - params_erode_dilate

return jnp.linalg.norm(diff) / jnp.linalg.norm(jnp.ones_like(diff))

# Objective function to be passed to the optimization algorithm.

def obj(

design_param, beta: float = 1.0, step_num: int = None, verbose: bool = False

) -> float:

sim = make_adjoint_sim(design_param, beta)

task_name = "inv_des"

if step_num:

task_name += f"_step_{step_num}"

sim_data = run(sim, task_name=task_name, verbose=verbose)

fom_val = fom(sim_data)

feature_size_penalty = penalty(design_param, beta=beta)

J = fom_val - feature_size_penalty

return J, sim_data

# Function to calculate the objective function value and its

# gradient with respect to the design parameters.

obj_grad = value_and_grad(obj, has_aux=True)

Next we will define the optimizer using optax. We will save the optimization progress in a pickle file. If that file is found, it will pick up the optimization from the last state. Otherwise, we will create a blank history.

[13]:

import optax

import pickle

# hyperparameters

learning_rate = 0.3

optimizer = optax.adam(learning_rate=learning_rate)

# where to store history

history_fname = "misc/grating_coupler_history.pkl"

def save_history(history_dict: dict) -> None:

"""Convenience function to save the history to file."""

with open(history_fname, "wb") as file:

pickle.dump(history_dict, file)

def load_history() -> dict:

"""Convenience method to load the history from file."""

with open(history_fname, "rb") as file:

history_dict = pickle.load(file)

return history_dict

Checking For a Previous Optimization#

If history_fname is a valid file, the results of a previous optimization are loaded, then the optimization will continue from the last iteration step. If the optimization was completed, only the final structure will be simulated. The pickle file used in this notebook can be downloaded from our documentation repo.

[14]:

try:

history_dict = load_history()

opt_state = history_dict["opt_states"][-1]

params = history_dict["params"][-1]

num_iters_completed = len(history_dict["params"])

print("Loaded optimization checkpoint from file.")

print(

f"Found {num_iters_completed} iterations previously completed out of {total_iter} total."

)

if num_iters_completed < total_iter:

print(f"Will resume optimization.")

else:

print("Optimization completed, will return results.")

except FileNotFoundError:

params = np.array(init_par)

opt_state = optimizer.init(params)

history_dict = dict(

values=[],

params=[],

gradients=[],

opt_states=[opt_state],

data=[],

beta=[],

)

Loaded optimization checkpoint from file.

Found 75 iterations previously completed out of 75 total.

Optimization completed, will return results.

[15]:

iter_done = len(history_dict["values"])

for i in range(iter_done, total_iter):

print(f"iteration = ({i + 1} / {total_iter})")

# compute gradient and current objective funciton value

perc_done = i / (total_iter - 1)

beta_i = beta_min * (1 - perc_done) + beta_max * perc_done

(value, sim_data_i), gradient = obj_grad(params, beta=beta_i)

# outputs

print(f"\tbeta = {beta_i}")

print(f"\tJ = {value:.4e}")

print(f"\tgrad_norm = {np.linalg.norm(gradient):.4e}")

# compute and apply updates to the optimizer based on gradient (-1 sign to maximize obj_fn)

updates, opt_state = optimizer.update(-gradient, opt_state, params)

params = optax.apply_updates(params, updates)

# cap parameters between 0 and 1

params = jnp.minimum(params, 1.0)

params = jnp.maximum(params, 0.0)

# save history

history_dict["values"].append(value)

history_dict["params"].append(params)

history_dict["beta"].append(beta_i)

history_dict["gradients"].append(gradient)

history_dict["opt_states"].append(opt_state)

# history_dict["data"].append(sim_data_i) # uncomment to store data, can create large files

save_history(history_dict)

Optimization Results#

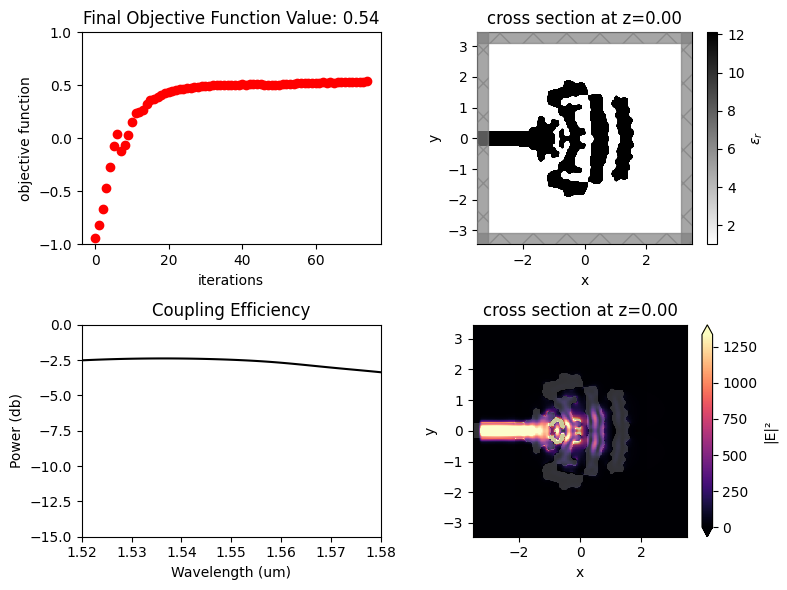

After 150 iterations, a coupling efficiency value of 0.71 (-1.48 dB) was achieved at the central wavelength.

[16]:

obj_vals = np.array(history_dict["values"])

final_par = history_dict["params"][-1]

final_beta = history_dict["beta"][-1]

[17]:

fig, ax = plt.subplots(1, 1, figsize=(6, 4))

ax.plot(obj_vals, "ro")

ax.set_xlabel("iterations")

ax.set_ylabel("objective function")

ax.set_ylim(-1, 1)

ax.set_title(f"Final Objective Function Value: {obj_vals[-1]:.2f}")

plt.show()

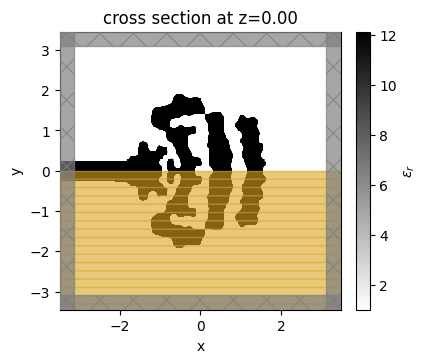

The final grating coupler structure is well binarized, with mostly black (eps_max) and white (eps_min) regions.

[18]:

fig, ax = plt.subplots(1, figsize=(4, 4))

sim_final = make_adjoint_sim(final_par, beta=final_beta, unfold=True)

sim_final = sim_final.to_simulation()[0]

sim_final.plot_eps(z=0, source_alpha=0, monitor_alpha=0, ax=ax)

plt.show()

Once the inverse design is complete, we can visualize the field distributions and the wavelength dependent coupling efficiency.

[19]:

# Field monitors to visualize the final fields.

field_xy = td.FieldMonitor(

size=(td.inf, td.inf, 0),

freqs=[freq],

name="field_xy",

)

field_xz = td.FieldMonitor(

size=(td.inf, 0, td.inf),

freqs=[freq],

name="field_xz",

)

# Monitor to compute the grating coupler efficiency.

gc_efficiency = td.ModeMonitor(

center=[mon_pos_x, 0, 0],

size=[0, mon_w, mon_h],

freqs=freqs,

mode_spec=mode_spec,

name="gc_efficiency",

)

sim_final = sim_final.copy(update=dict(monitors=(field_xy, field_xz, gc_efficiency)))

sim_data_final = web.run(sim_final, task_name="inv_des_final")

09:48:29 -03 Created task 'inv_des_final' with task_id 'fdve-77054d4d-b683-4fe9-932f-24e5fee344ef' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-77054d4d-b68 3-4fe9-932f-24e5fee344ef'.

09:48:39 -03 status = queued

09:48:43 -03 status = preprocess

09:48:50 -03 Maximum FlexCredit cost: 0.204. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

09:49:19 -03 early shutoff detected at 16%, exiting.

status = postprocess

09:49:24 -03 status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-77054d4d-b68 3-4fe9-932f-24e5fee344ef'.

09:49:28 -03 loading simulation from simulation_data.hdf5

[20]:

mode_amps = sim_data_final["gc_efficiency"]

coeffs_f = mode_amps.amps.sel(direction="-")

power_0 = np.abs(coeffs_f.sel(mode_index=0)) ** 2

power_0_db = 10 * np.log10(power_0)

sim_plot = sim_final.updated_copy(

symmetry=(0, 0, 0), monitors=(field_xy, field_xz, gc_efficiency)

)

sim_data_plot = sim_data_final.updated_copy(simulation=sim_plot)

f, ax = plt.subplots(2, 2, figsize=(8, 6), tight_layout=True)

sim_plot.plot_eps(z=0, source_alpha=0, monitor_alpha=0, ax=ax[0, 1])

ax[1, 0].plot(wl_range, power_0_db, "-k")

ax[1, 0].set_xlabel("Wavelength (um)")

ax[1, 0].set_ylabel("Power (db)")

ax[1, 0].set_ylim(-15, 0)

ax[1, 0].set_xlim(wl - bw / 2, wl + bw / 2)

ax[1, 0].set_title("Coupling Efficiency")

sim_data_plot.plot_field("field_xy", "E", "abs^2", z=0, ax=ax[1, 1])

ax[0, 0].plot(obj_vals, "ro")

ax[0, 0].set_xlabel("iterations")

ax[0, 0].set_ylabel("objective function")

ax[0, 0].set_ylim(-1, 1)

ax[0, 0].set_title(f"Final Objective Function Value: {obj_vals[-1]:.2f}")

plt.show()

[21]:

loss_db = max(power_0_db)

print(f"optimized loss of {loss_db:.2f} dB")

optimized loss of -2.38 dB

Lastly, we export the final grating coupler design to GDS using the function .to_gds_file.

[22]:

sim_final.to_gds_file(

fname="./misc/inverse_designed_gc.gds",

z=0,

permittivity_threshold=(eps_max + eps_min) / 2,

frequency=freq,

)