Exceptional coupling for waveguide crosstalk reduction#

This notebook contains large simulations. Running the entire notebook will cost about 20 FlexCredits.

The current technological trend emphasizes the dense integration of photonic components on a chip. However, as the proximity between these components increases, the issue of crosstalk becomes more significant and detrimental. Therefore, we need to apply other design ideas to actively minimize the crosstalk.

In this notebook, we investigate the crosstalk between two strip waveguides, which are fundamental photonic components. We demonstrate that the utilization of anisotropic metamaterial (also known as subwavelength grating (swg)) cladding enables remarkable reduction of crosstalk by leveraging the exceptional coupling as proposed in the article

Md Borhan Mia, Syed Z. Ahmed, Ishtiaque Ahmed, Yun Jo Lee, Minghao Qi, and Sangsik Kim, "Exceptional coupling in photonic anisotropic metamaterials for extremely low waveguide crosstalk," Optica 7, 881-887 (2020) DOI: 10.1364/OPTICA.394987. The waveguide with anisotropic metamaterial cladding is shown to have an extreme skin depth and thus it’s termed eskid waveguide. The reduced skin depth leads to reduced crosstalk. Moreover, at a certain

wavelength, exceptional coupling occurs where the symmetric and antisymmetric modes have identical effective index and the coupling is zero in principle.

For more integrated photonic examples such as the waveguide crossing, the strip to slot waveguide converter, and the broadband directional coupler, please visit our examples page.

[1]:

import numpy as np

import matplotlib.pyplot as plt

import gdstk

import tidy3d as td

import tidy3d.web as web

Simulation Setup#

For the simulation, we will investigate the wavelength range between 1500 nm and 1600 nm.

[2]:

lda0 = 1.55 # central wavelength

freq0 = td.C_0 / lda0 # central frequency

ldas = np.linspace(1.5, 1.6, 101) # wavelength range

freqs = td.C_0 / ldas # frequency range

fwidth = 0.5 * (np.max(freqs) - np.min(freqs)) # width of the source frequency range

Define materials.

[3]:

n_si = 3.43 # silicon refractive index

si = td.Medium(permittivity=n_si**2)

n_sio2 = 1.444 # silicon oxide refractive index

sio2 = td.Medium(permittivity=n_sio2**2)

Define geometric parameters.

[4]:

w = 0.45 # waveguide width

h = 0.22 # waveguide thickness

p = 0.1 # period of the swg

frac = 0.5 # filling fraction

N = 5 # number of grating periods

L = 100 # length of the coupling region

inf_eff = 1e2 # effective infinity

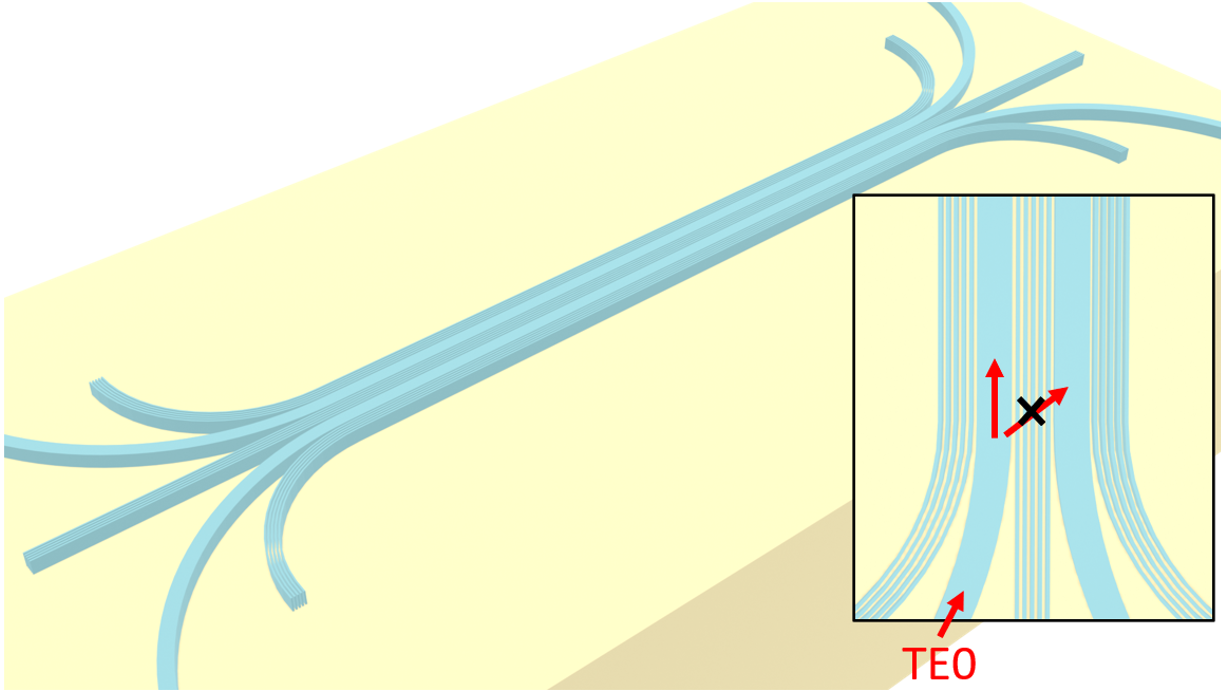

Define the waveguides and the anisotropic metamaterial cladding. The most convenient way is to use gdstk.

[5]:

R = 10 # radius of the bend

cell_eskid = gdstk.Cell("eskid") # define a cell for the eskid waveguides

cell_ref = gdstk.Cell("ref") # define a cell for bare strip waveguides

# define the top strip waveguide

path_1 = gdstk.RobustPath(initial_point=(-L / 2 - R, inf_eff), width=w, layer=1, datatype=0)

path_1.vertical(y=(N + 0.5) * p / 2 + w / 2 + R)

path_1.arc(radius=R, initial_angle=-np.pi, final_angle=-np.pi / 2)

path_1.horizontal(x=L / 2)

path_1.arc(radius=R, initial_angle=-np.pi / 2, final_angle=0)

path_1.vertical(y=inf_eff)

cell_eskid.add(path_1)

cell_ref.add(path_1)

# define the bottom strip waveguide

path_2 = path_1.copy()

path_2.mirror(p1=(1, 0))

cell_eskid.add(path_2)

cell_ref.add(path_2)

# define the swg between the waveguides

path_3 = gdstk.RobustPath(

initial_point=(-1.2 * L / 2, 0),

width=[frac * p, frac * p, frac * p, frac * p, frac * p],

offset=p,

layer=1,

datatype=0,

)

path_3.horizontal(x=1.2 * L / 2)

cell_eskid.add(path_3)

# define the swg on the top

path_4 = gdstk.RobustPath(

initial_point=(-L / 2 - R / 2, (N + 0.5) * p + w + R / 2),

width=[frac * p, frac * p, frac * p, frac * p, frac * p],

offset=p,

layer=1,

datatype=0,

)

path_4.arc(radius=R / 2, initial_angle=-np.pi, final_angle=-np.pi / 2)

path_4.horizontal(x=L / 2)

path_4.arc(radius=R / 2, initial_angle=-np.pi / 2, final_angle=0)

cell_eskid.add(path_4)

# define the swg on the bottom

path_5 = path_4.copy()

path_5.mirror(p1=(1, 0))

cell_eskid.add(path_5);

[5]:

<gdstk.Cell at 0x7fcd5fc23bf0>

After the gds cell is created, we can define Tidy3D geometries from the gds cell and visualize them.

[6]:

# define tidy3d geometries from the gds cell

eskid_geo = td.PolySlab.from_gds(

cell_eskid,

gds_layer=1,

axis=2,

slab_bounds=(-h / 2, h / 2),

)

# plot the geometries

fig, ax = plt.subplots()

for geo in eskid_geo:

geo.plot(z=0, ax=ax)

ax.set_xlim(-0.7 * L, 0.7 * L)

ax.set_ylim(-0.2 * R, 0.2 * R)

ax.set_aspect("auto")

plt.show()

Define Tidy3D Structures using the previously defined geometries and materials.

[7]:

# define tidy3d structures from the geometries

eskid_structure = [td.Structure(geometry=geo, medium=si) for geo in eskid_geo]

# define the substrate structure

substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -inf_eff, -inf_eff), rmax=(inf_eff, inf_eff, -h / 2)

),

medium=sio2,

)

Define a ModeSource to excite the TE0 mode at the input waveguide and then define two ModeMonitors at the through port and cross port to measure the transmission. And finally we add a FieldMonitor at the \(z=0\) plane to visualize the power propagation and coupling.

[8]:

# add a mode source as excitation

mode_spec = td.ModeSpec(num_modes=1, target_neff=n_si)

input_x = -L / 2 - R

input_y = (N + 1) * p / 2 + w / 2 + R + lda0 / 4

mode_source = td.ModeSource(

center=(input_x, input_y, 0),

size=(5 * w, 0, 9 * h),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="-",

mode_spec=mode_spec,

mode_index=0,

)

# add a mode monitor to measure transmission at the through port

mode_monitor_I1 = td.ModeMonitor(

center=(-input_x, input_y, 0),

size=(5 * w, 0, 9 * h),

freqs=freqs,

mode_spec=mode_spec,

name="I1",

)

# add a mode monitor to measure transmission at the cross port

mode_monitor_I2 = td.ModeMonitor(

center=(-input_x, -input_y, 0),

size=(5 * w, 0, 9 * h),

freqs=freqs,

mode_spec=mode_spec,

name="I2",

)

# add a filed monitor to visualize field distribution at z=0

field_monitor = td.FieldMonitor(

size=(td.inf, td.inf, 0), freqs=[freq0], interval_space=(3, 3, 1), name="field"

)

[19:05:49] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

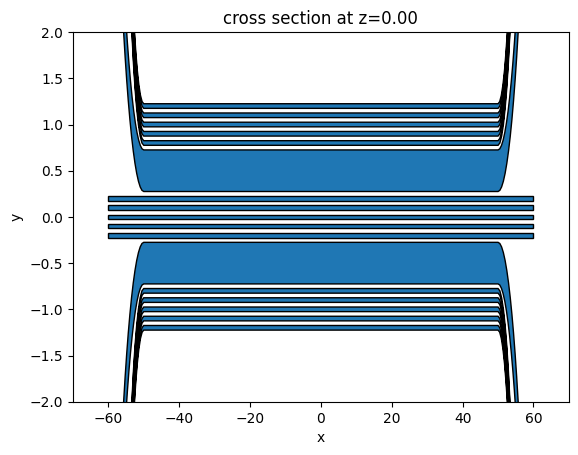

Define a Tidy3D Simulation using the components above. Due to the thin anisotropic metamaterial claddings, a fine grid needs to be used to ensure an accurate simulation. Here we use the automatic nonuniform grid with min_steps_per_wvl set to 20.

[9]:

# simulation domain size

Lx = 1.25 * L

Ly = 2.4 * R

Lz = 9 * h

sim_size = (Lx, Ly, Lz)

run_time = 5e-12 # simulation run time

# construct simulation

sim_eskid = td.Simulation(

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=20, wavelength=lda0),

structures=eskid_structure + [substrate],

sources=[mode_source],

monitors=[mode_monitor_I1, mode_monitor_I2, field_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

)

# plot the simulation

sim_eskid.plot(z=0)

plt.show()

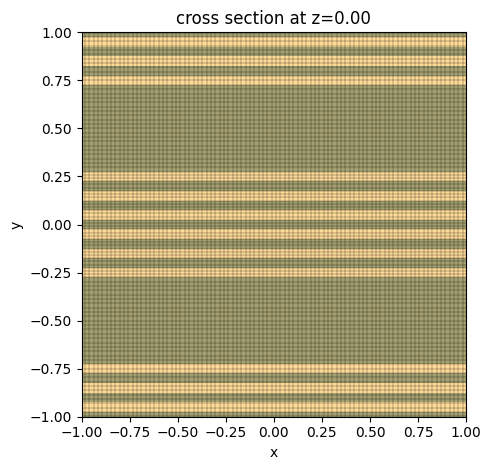

Since the simulation contains very thin waveguides, it’s crucial to have a sufficiently small grid size to resolve them. We can inspect the grid by using the plot_grid method.

[10]:

# inspect the grid

ax = sim_eskid.plot(z=0, hlim=[-1,1], vlim=[-1,1])

sim_eskid.plot_grid(z=0, ax=ax, hlim=[-1,1], vlim=[-1,1])

plt.show()

Once everything is confirmed, we submit the simulation job to the server. The fine grid combined with the large simulation domain will lead to a higher FlexCredit cost. Before running the simulation, we can get a cost estimation using estimate_cost. This prevents us from accidentally running large jobs that we set up by mistake. The estimated cost is the maximum cost corresponding to running all the time steps.

[11]:

job = web.Job(simulation=sim_eskid, task_name="eskid", verbose=True)

estimated_cost = web.estimate_cost(job.task_id)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 8a858953-f5c8-4798-bf49-8ad896eb2ef1v1'.

The estimated maximum cost is 13.799 Flex Credits.

The cost is reasonable given the simulation size so we can run the simulation now.

[12]:

sim_data_eskid = job.run(path="data/eskid.hdf5")

Result Analysis and Visualization#

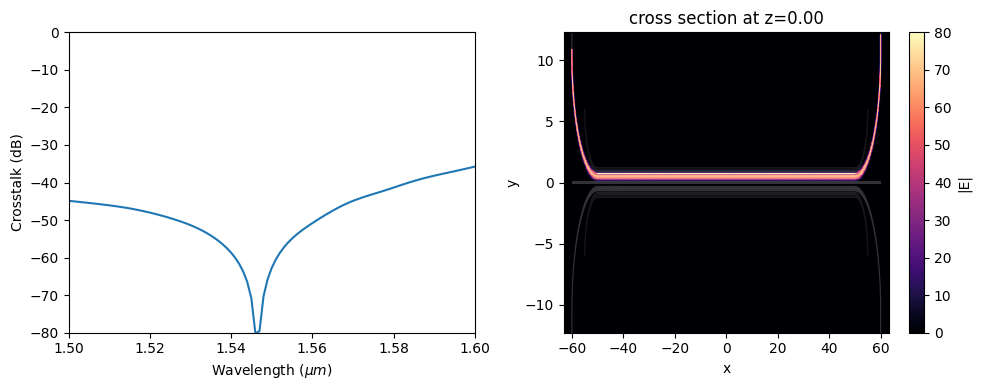

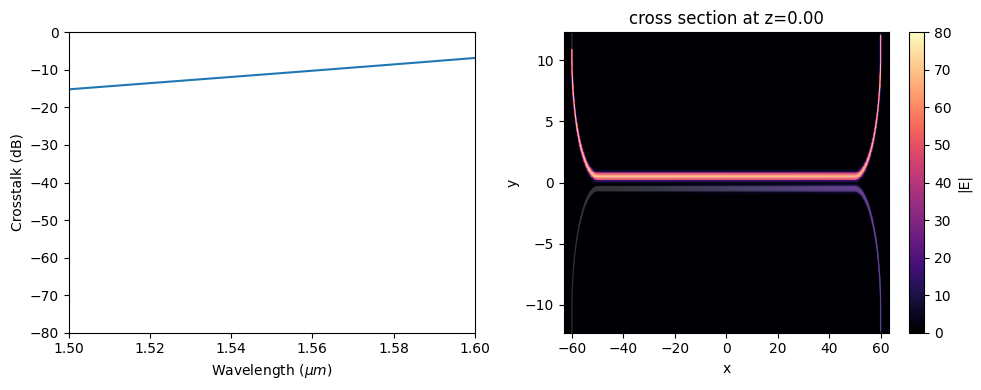

We define a helper function postprocess to plot the crosstalk and field distribution. The crosstalk is defined as \(I_2/I_1\), where \(I_1\) is the power transmitted to the through port and \(I_2\) is the power transmitted to the cross port.

[13]:

def postprocess(sim_data):

I1 = np.abs(sim_data["I1"].amps.sel(mode_index=0, direction="+")) ** 2

I2 = np.abs(sim_data["I2"].amps.sel(mode_index=0, direction="-")) ** 2

crosstalk = I2 / I1

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(10, 4), tight_layout=True)

ax1.plot(ldas, 10 * np.log10(crosstalk))

ax1.set_xlabel("Wavelength ($\mu m$)")

ax1.set_xlim(np.min(ldas), np.max(ldas))

ax1.set_ylim(-80, 0)

ax1.set_ylabel("Crosstalk (dB)")

sim_data.plot_field("field", "E", "abs", vmin=0, vmax=80, ax=ax2)

ax2.set_aspect("auto")

plt.show()

Call the postprocess function on the simulation data of the eskid waveguide simulation. Here we see the crosstalk is below -40 dB around the 100 nm bandwidth. At about 1550 nm, exception coupling occurs and the crosstalk is well below -80 dB. The exceptional coupling wavelength can be effectively tuned by changing the geometric parameters such as the waveguide width.

From the field distribution plot, we see the field stays at the top waveguide throughout the coupling regime, confirming the low crosstalk.

[14]:

postprocess(sim_data_eskid)

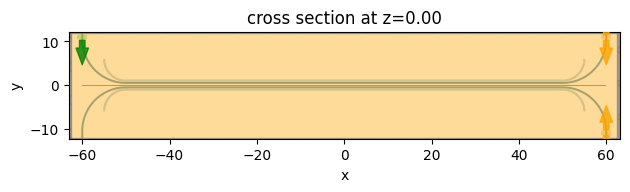

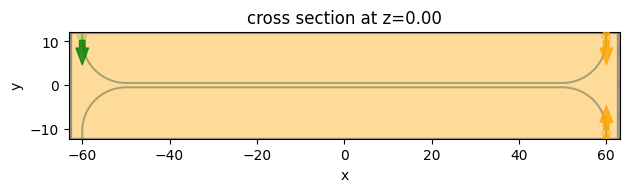

Reference Simulation#

The crosstalk of the eskid waveguide has been shown to be very low. As a comparison, we simulate two strip waveguides with the same spacing without the anisotropic metamaterial claddings.

[15]:

# define geometries for the bare strip waveguides

ref_geo = td.PolySlab.from_gds(

cell_ref,

gds_layer=1,

axis=2,

slab_bounds=(-h / 2, h / 2),

)

# define structures for the bare strip waveguides

ref_structure = [td.Structure(geometry=geo, medium=si) for geo in ref_geo]

# copy the simulation and update the structures to bare strip waveguides

sim_ref = sim_eskid.copy(update={"structures": ref_structure + [substrate]})

# plot simulation

sim_ref.plot(z=0)

plt.show()

submit the simulation job to the server.

[16]:

sim_data_ref = web.run(sim_ref, task_name="ref", path="data/ref.hdf5")

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- d791f8e1-055f-45ee-9ef6-af786f86b4bdv1'.

Apply the same visualization to the simulation data. We can see that the crosstalk is much larger in the bare strip waveguide case, around -10 dB. In the field distribution plot, a noticeable amount of energy is coupled to the lower waveguide. This comparison further validifies the effectiveness of the anisotropic metamaterial cladding design for crosstalk suppression.

[17]:

postprocess(sim_data_ref)

Final Remark#

The proposed design in this example achieves exceptional coupling only for the TE mode. A different anisotropic metamaterial-based design achieving zero crosstalk for the TM mode is proposed by the same research group. For detail, please refer to Kabir, M.F., Mia, M.B., Ahmed, I. et al. Anisotropic leaky-like perturbation with subwavelength gratings enables zero crosstalk. Light Sci Appl 12, 135 (2023) DOI:10.1038/s41377-023-01184-5.

[ ]: