Focusing apodized grating coupler#

Running the entire notebook costs more than 1 FlexCredit.

In this notebook, we will design a focusing apodized grating coupler (GC) to vertically couple light in/out photonic integrated circuits (PICs). We will build the grating coupler following the design guidelines presented in the following paper: R. Marchetti, C. Lacava, A. Khokhar, et al. “High-efficiency grating-couplers: demonstration of a new design strategy,” Sci Rep 7, 16670 (2017) DOI: 10.1038/s41598-017-16505-z. In a previous case study, we modeled an uniform grating coupler. The apodized grating coupler demonstrated in this notebook shows superior performance.

For more integrated photonic examples such as the 8-Channel mode and polarization de-multiplexer, the broadband bi-level taper polarization rotator-splitter, and the broadband directional coupler, please visit our examples page.

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials.

FDTD simulations can diverge due to various reasons. If you run into any simulation divergence issues, please follow the steps outlined in our troubleshooting guide to resolve it.

[1]:

# Standard python imports.

import numpy as np

import matplotlib.pylab as plt

import gdstk

# Import regular tidy3d.

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins import waveguide

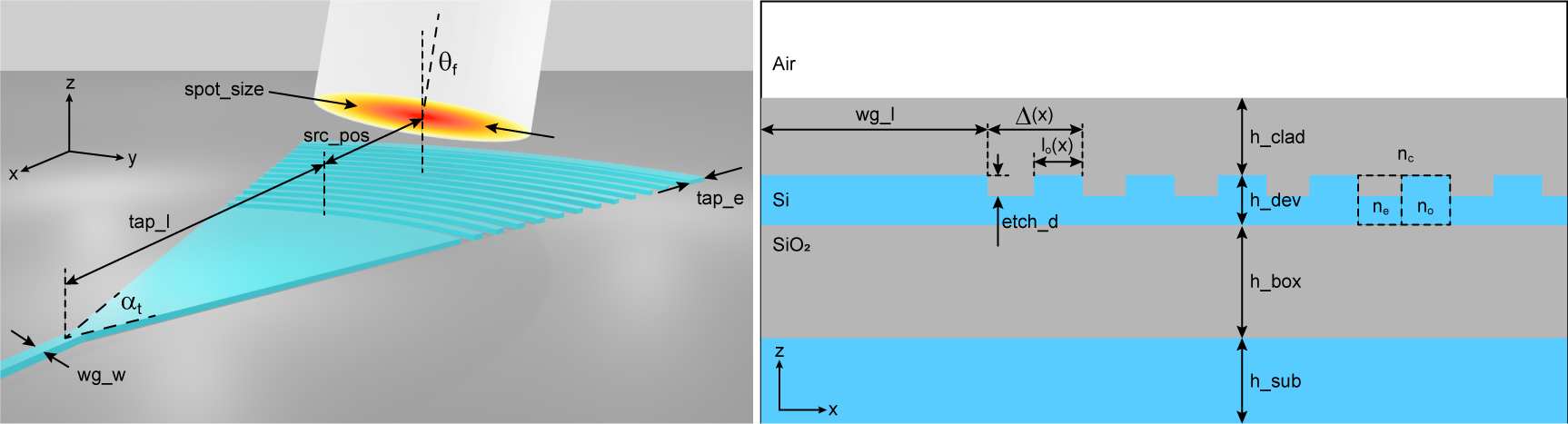

Grating Coupler Structure#

The GC structure is based on a standard silicon-on-insulator (SOI) wafer with a device layer of 220 nm. By linearly varying the fill-factor \(F(x) = F_{0} - R\cdot x\), where \(F_{0}\) is the fill-factor of the first grating element and \(R\) is the apodization factor, the power radiated by the first elements of the grating is reduced, and the mode matching between the output waveguide and the grating section is improved, thus reducing reflections. To further improve the grating coupling efficiency, the grating element size \(\Delta\) is let to vary, so satisfying the Bragg condition along the whole grating.

The effective index of a grating element \(n_{eff}(x)\) then depends on the fill-factor \(F(x)\), and the mode indices obtained in the etched (\(n_{e}\)) and non-etched (\(n_{o}\)) sections of the grating, as

\begin{equation*} n_{eff}(x) = F(x)n_{o} + [1 - F(x)]n_{e}. \tag{1} \end{equation*}

From the effective index, the size of each grating element can be calculated as:

\begin{equation*} \Delta(x) = \frac{\lambda_{0}}{n_{e} - n_{c}sin(\theta_{gc}) + F(x)\Delta n} \tag{2} \end{equation*}

where \(\lambda_{0}\) is the center wavelength, \(n_{c}\) is the cladding refractive index, \(\theta_{gc}\) is the light incidence angle with respect to the grating normal, and \(\Delta n = n_{o} - n_{e}\).

A focusing design of GC is usually adopted to reduce device footprint. In this way, the grating lines (indicated by an integer \(q\)) are curved forming ellipses with common focal points, as in Eq. 3 (Ralf Waldhäusl, Bernd Schnabel, Peter Dannberg, Ernst-Bernhard Kley, Andreas Bräuer, and Wolfgang Karthe, "Efficient Coupling into Polymer Waveguides by Gratings," Appl. Opt. 36, 9383-9390 (1997)DOI: 10.1364/AO.36.009383).

\begin{equation*} q\lambda_{0} = n_{eff}\sqrt{x^{2} + y^{2}} - xn_{c}sin(\theta_{f}). \tag{3} \end{equation*}

For simplicity, we will approximate the grating lines by concentric circles, which is a reasonable assumption considering small incidence angles.

[2]:

# Grating coupler set up.

h_dev = 0.220 # Device layer thickness (um).

h_box = 2.0 # BOX layer thickness (um).

h_clad = 0.78 # Cladding layer thickness (um).

h_sub = 0.8 # Silicon substrate thickness (um).

etch_d = 0.110 # GC etch depth (um).

alpha_t = 40 # GC taper opening angle (degrees).

tap_l = 16 # Taper length (um).

tap_e = 1 # Additional length after GC elements (um).

n_p = 25 # Number of grating elements.

r_i = 0.0275 # Initial value for the apodization parameter.

min_feature = 0.1 # Minimum feature size (um).

spot_size = 10.4 # Single-mode fiber (SMF) spot-size (um).

theta_f = 14.5 # Fiber tilt angle w.r.t the z-axis (degrees).

src_pos = 5.0 # Source position w.r.t the position of the first GC line (um).

src_offset = 0.05 # Source offset w.r.t GC surface (um).

wg_l = 4 # Output waveguide length (um).

wg_w = 0.5 # Output waveguide width (um).

gc_file = "misc/Focusing_GC.gds" # File name to export GC GDS file.

# Materials.

n_si = 3.48 # Silicon refractive index.

n_sio2 = 1.44 # SiO2 refractive index.

n_c = 1.44 # Cladding refractive index.

# Simulation set up.

wl = 1.55 # Center simulation wavelength (um).

bw = 0.06 # Simulation wavelength bandwidth (um).

n_wl = 61 # Number of wavelength points in monitors.

run_time = 2e-12 # Run time parameter for simulation (s).

We will calculate and define some parameters used throughout the notebook.

[3]:

# Material definitions.

mat_si = td.Medium(permittivity=n_si**2) # Waveguide material.

mat_sio2 = td.Medium(permittivity=n_sio2**2) # BOX material.

mat_clad = td.Medium(permittivity=n_c**2) # Cladding material.

# Light incidence angle on the GC.

theta_gc = np.arcsin(np.sin(theta_f * np.pi / 180) / n_c) * 180 / np.pi

# Wavelengths and frequencies.

wl_max = wl + bw / 2

wl_min = wl - bw / 2

wl_range = np.linspace(wl_min, wl_max, n_wl)

freq = td.C_0 / wl

freqs = td.C_0 / wl_range

freqw = 0.5 * (freqs[0] - freqs[-1])

So, let’s define some functions to create the grating coupler.

[4]:

# Function to calculate the values of filling fractions and grating element sizes.

def calc_gc_par(

no: float = 2.65,

ne: float = 2.25,

nc: float = 1.0,

theta: float = 10.0,

lamb: float = 1.55,

N: int = 25,

R: float = 0.025,

min_feature: float = 0.140,

):

del_x = np.zeros((N))

f_x = np.zeros((N))

theta_rad = theta * np.pi / 180

del_0 = lamb / (no - nc * np.sin(theta_rad))

f_0 = (del_0 - min_feature) / del_0

x = 0

for i in range(0, N):

f_x[i] = f_0 - R * x

del_x[i] = lamb / (ne - nc * np.sin(theta_rad) + f_x[i] * (no - ne))

x += del_x[i]

return (del_x, f_x)

# Function to create the 3D GC structure.

def build_gc(

del_x: np.ndarray = None,

f_x: np.ndarray = None,

alpha_t: float = 40.0,

tap_l: float = 16,

tap_e: float = 1,

etch_d: float = 0.1,

wg_w: float = 0.50,

wg_t: float = 0.22,

wg_l: float = 5,

gds_file: str = [],

):

lib = gdstk.Library()

gc_cell = lib.new_cell("GC")

alpha_rad = alpha_t * np.pi / 180

xf = wg_l - ((wg_w / 2 / np.sin(alpha_rad / 2)) * np.cos(alpha_rad / 2))

yf = 0

r = tap_l

# GC taper section.

gc_slice = gdstk.ellipse(

(xf, yf),

r,

initial_angle=-alpha_rad / 2,

final_angle=alpha_rad / 2,

layer=1,

datatype=1,

tolerance=0.0005,

)

gc_cell.add(gc_slice)

# GC lines.

for d, f in zip(del_x, f_x):

r += d

ri = r - f * d

gc_line = gdstk.ellipse(

(xf, yf),

r,

inner_radius=ri,

initial_angle=-alpha_rad / 2,

final_angle=alpha_rad / 2,

layer=1,

datatype=1,

tolerance=0.0005,

)

gc_cell.add(gc_line)

# GC extension.

ri = r

r += tap_e

gc_ext = gdstk.ellipse(

(xf, yf),

r,

inner_radius=ri,

initial_angle=-alpha_rad / 2,

final_angle=alpha_rad / 2,

layer=1,

datatype=1,

tolerance=0.0005,

)

gc_cell.add(gc_ext)

# GC non-etched material.

gc_full_slice = gdstk.ellipse(

(xf, yf),

r,

initial_angle=-alpha_rad / 2,

final_angle=alpha_rad / 2,

layer=2,

datatype=2,

tolerance=0.0005,

)

gc_cell.add(gc_full_slice)

# Input/output waveguide.

wg_v = [

(wg_l, -wg_w / 2),

(-3 * wg_l, -wg_w / 2),

(-3 * wg_l, +wg_w / 2),

(wg_l, +wg_w / 2),

]

gc_wg = gdstk.Polygon(wg_v, layer=3, datatype=3)

gc_cell.add(gc_wg)

# Build the Tidy3D PolySlab and Structure objects.

gc_etch = td.PolySlab.from_gds(

gc_cell, gds_layer=1, axis=2, slab_bounds=(wg_t / 2 - etch_d, wg_t / 2)

)

gc_non_etch = td.PolySlab.from_gds(

gc_cell, gds_layer=2, axis=2, slab_bounds=(-wg_t / 2, wg_t / 2 - etch_d)

)[0]

wg = td.PolySlab.from_gds(

gc_cell, gds_layer=3, axis=2, slab_bounds=(-wg_t / 2, wg_t / 2)

)[0]

gc_struct = td.Structure(

geometry=td.GeometryGroup(geometries=(gc_non_etch, *gc_etch, wg)), medium=mat_si

)

# Outputs the GDS file.

if gds_file:

lib.write_gds(gds_file)

return gc_struct

Simulation Set Up#

We will create a function to build different types of simulations based on the value of sim_mode:

sim_mode = "sweep": builds an in-coupling simulation using only one mode monitor.sim_mode = "visualization": builds an in-coupling simulation including field and flux monitors.sim_mode = "out_coupling": builds an out-coupling simulation using a field projection monitor.

To define the grating structure, we will perform 2D simulations by running multiple parameter sweeps. Once this is completed, the final response will be obtained using 3D simulations. Details about setting up 2D simulations can be found in the 2D ring resonator notebook.

[5]:

# Function to create the simulation.

def build_sim(

sim_mode="sweep",

sim_dim="3D",

no=2.65,

ne=2.25,

nc=1.0,

src_pos=src_pos,

R=r_i,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=etch_d,

gds_file=[],

):

# Calculates the GC element sizes and fill-factors.

del_x, f_x = calc_gc_par(

no=no,

ne=ne,

nc=nc,

theta=theta_gc,

lamb=wl,

N=n_p,

R=R,

min_feature=min_feature,

)

# GC related parameters.

gc_offset = (wg_w / np.sin(alpha_t * np.pi / 180)) * np.cos(alpha_t * np.pi / 180)

gc_0 = wg_l + tap_l - gc_offset

gc_length = tap_l + np.sum(del_x) + tap_e - gc_offset

pml_offset = 0.7 * wl

# Simulation size.

size_z = h_sub + h_box + h_dev + h_clad + pml_offset

size_x = wg_l + gc_length + wl

size_y = 0.95 * gc_length * np.tan(alpha_t * np.pi / 180) if sim_dim == "3D" else 0

center_z = size_z / 2 - pml_offset - h_clad - h_dev / 2

# Build the GC structure.

gc_struct = build_gc(

del_x=del_x,

f_x=f_x,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=etch_d,

wg_w=wg_w,

wg_t=h_dev,

wg_l=wg_l,

gds_file=gds_file,

)

# Box layer.

_inf = 1000

sio2_box = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-_inf, -_inf, -h_dev / 2 - h_box), rmax=(_inf, _inf, -h_dev / 2)

),

medium=mat_sio2,

)

# Cladding layer.

cladding = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-_inf, -_inf, -h_dev / 2), rmax=(_inf, _inf, h_dev / 2 + h_clad)

),

medium=mat_clad,

)

# Substrate.

si_sub = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-_inf, -_inf, -_inf), rmax=(_inf, _inf, -h_dev / 2 - h_box)

),

medium=mat_si,

)

if sim_mode == "sweep" or sim_mode == "visualization":

# Gaussian source focused above the grating coupler.

source = td.GaussianBeam(

center=(gc_0 + src_pos, 0, h_dev / 2 + h_clad + src_offset),

size=(

1.2 * spot_size,

1.2 * spot_size

if sim_dim == "3D"

else td.inf, # Make it infinity in 2D.

0,

),

source_time=td.GaussianPulse(freq0=freq, fwidth=freqw),

pol_angle=np.pi / 2,

angle_theta=theta_f * np.pi / 180.0,

direction="-",

num_freqs=7,

waist_radius=spot_size / 2,

)

# Mode monitor.

mode_spec = td.ModeSpec(num_modes=1, target_neff=n_si)

mode_monitor = td.ModeMonitor(

center=[0.5 * wl, 0, 0],

size=[0, 4 * wg_w, 5 * h_dev],

freqs=freqs,

mode_spec=mode_spec,

name="mode_monitor",

)

monitors = [mode_monitor]

if sim_mode == "visualization":

# Add field and flux monitors.

field_monitor_xy = td.FieldMonitor(

center=(size_x / 2, 0, h_dev / 2 - etch_d / 2),

size=(td.inf, td.inf, 0),

freqs=[freq],

name="field_xy",

)

monitors.append(field_monitor_xy)

field_monitor_xz = td.FieldMonitor(

center=(size_x / 2, 0, 0),

size=(td.inf, 0, td.inf),

freqs=[freq],

name="field_xz",

)

monitors.append(field_monitor_xz)

flux_sub = td.FluxMonitor(

center=(size_x / 2, 0, -h_dev - h_box),

size=(td.inf, td.inf, 0),

freqs=freqs,

name="flux_sub",

)

monitors.append(flux_sub)

flux_ref = td.FluxMonitor(

center=(size_x / 2, 0, h_dev + h_clad + src_offset),

size=(td.inf, td.inf, 0),

freqs=freqs,

name="flux_reflected",

)

monitors.append(flux_ref)

else:

# Define a mode source that injects te fundamental mode.

mode_spec = td.ModeSpec(num_modes=1, target_neff=n_si)

source = td.ModeSource(

center=(0.5 * wl, 0, 0),

size=(0, 4 * wg_w, 5 * h_dev),

source_time=td.GaussianPulse(freq0=freq, fwidth=freqw),

direction="+",

mode_spec=mode_spec,

mode_index=0,

num_freqs=7,

)

# Add a near field monitor.

field_monitor_xy = td.FieldMonitor(

center=(size_x / 2, 0, h_dev / 2 + h_clad + src_offset),

size=(td.inf, td.inf, 0),

freqs=[freq],

name="near_field",

)

monitors = [field_monitor_xy]

field_monitor_xz = td.FieldMonitor(

center=(size_x / 2, 0, 0),

size=(td.inf, 0, td.inf),

freqs=[freq],

name="field_xz",

)

monitors.append(field_monitor_xz)

flux_back = td.FluxMonitor(

center=(0.25 * wl, 0, 0),

size=(0, td.inf, td.inf),

freqs=freqs,

name="flux_back",

)

monitors.append(flux_back)

# Refine the grid over the GC region.

refine_box = td.MeshOverrideStructure(

geometry=td.Box(center=(size_x / 2, 0, 0), size=(td.inf, td.inf, 2 * h_dev)),

dl=[0.02, 0.02 if sim_dim == "3D" else None, 0.02],

)

# Simulation

sim = td.Simulation(

center=(size_x / 2, 0, -center_z),

size=(size_x, size_y, size_z),

grid_spec=td.GridSpec.auto(

wavelength=wl,

min_steps_per_wvl=15,

override_structures=[refine_box],

),

structures=[si_sub, sio2_box, cladding, gc_struct],

sources=[source],

monitors=monitors,

boundary_spec=td.BoundarySpec(

x=td.Boundary.pml(),

y=td.Boundary.pml()

if sim_dim == "3D"

else td.Boundary.periodic(), # Make it periodic in 2D.

z=td.Boundary.pml(),

),

symmetry=(0, -1 if sim_dim == "3D" else 0, 0),

run_time=run_time,

)

return sim

Grating Coupler Visualization#

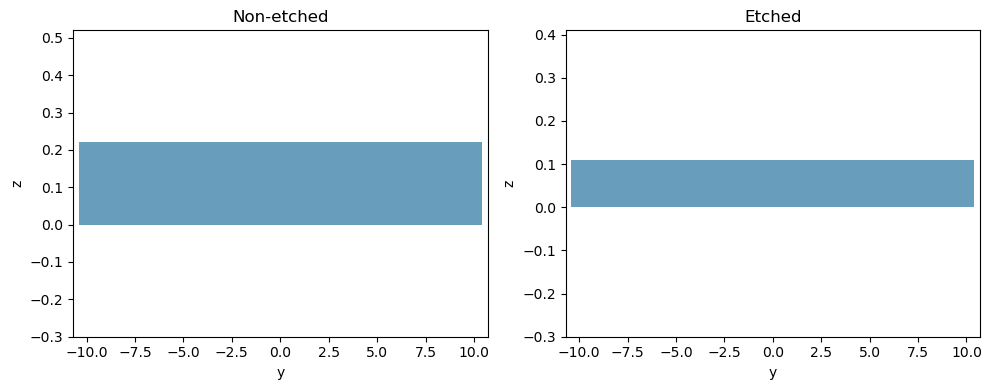

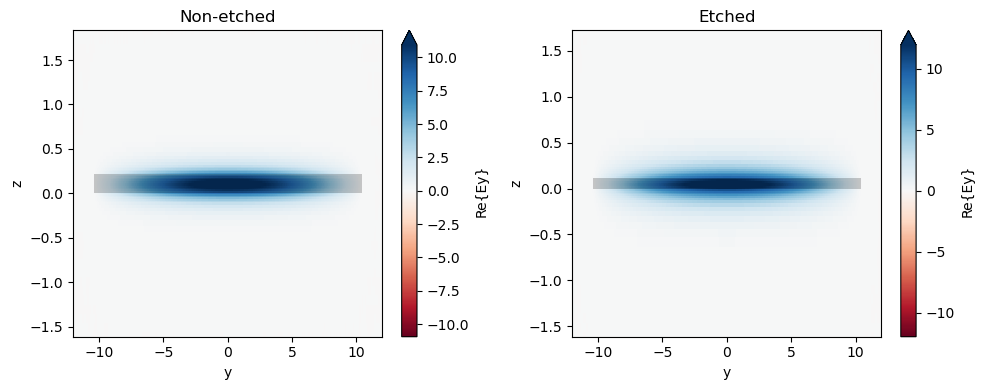

To verify if everything is correct, we will obtain the parameters \(n_{o}\) and \(n_{e}\), calculated using the waveguide plugin, and then visualize the grating coupler structure.

[6]:

# Definition of wide non-etched and etched waveguides.

wg_non_etch, wg_etch = [

waveguide.RectangularDielectric(

wavelength=wl,

core_width=2 * spot_size,

core_thickness=t,

core_medium=mat_si,

box_medium=mat_sio2,

clad_medium=mat_clad,

)

for t in [h_dev, h_dev - etch_d]

]

# Take a look at the waveguide cross-sections.

fig, ax = plt.subplots(1, 2, figsize=(10, 4), tight_layout=True)

_ = wg_non_etch.plot_structures(x=0, ax=ax[0])

ax[0].set_aspect("auto")

ax[0].set_title("Non-etched")

_ = wg_etch.plot_structures(x=0, ax=ax[1])

ax[1].set_aspect("auto")

ax[1].set_title("Etched")

plt.show()

[7]:

n_o = wg_non_etch.n_eff.values[0, 0]

n_e = wg_etch.n_eff.values[0, 0]

print(f"Non-etched waveguide effective index: {n_o:.3f}")

print(f"Etched waveguide effective index: {n_e:.3f}")

# Take a look at the waveguide fields.

fig, ax = plt.subplots(1, 2, figsize=(10, 4), tight_layout=True)

wg_non_etch.plot_field("Ey", mode_index=0, ax=ax[0])

ax[0].set_aspect("auto")

ax[0].set_title("Non-etched")

wg_etch.plot_field("Ey", mode_index=0, ax=ax[1])

ax[1].set_aspect("auto")

ax[1].set_title("Etched")

plt.show()

Non-etched waveguide effective index: 2.854

Etched waveguide effective index: 2.276

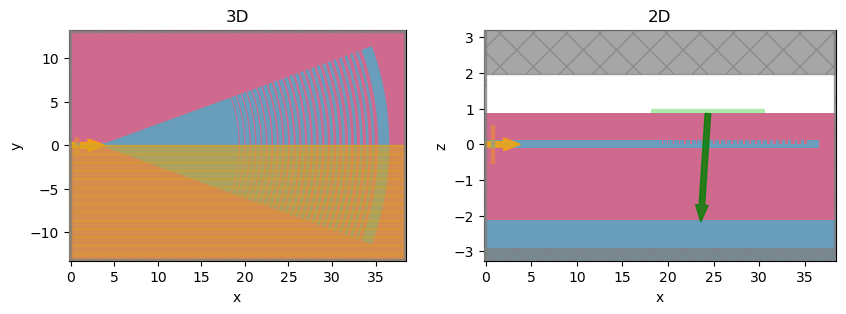

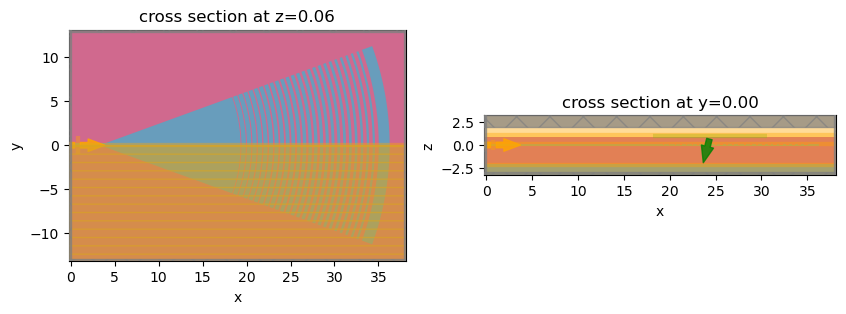

Let’s visualize both the 2D and 3D versions of the simulation.

[8]:

sim_3d = build_sim(

sim_mode="sweep",

sim_dim="3D",

no=n_o,

ne=n_e,

nc=n_c,

src_pos=src_pos,

R=r_i,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=etch_d,

)

sim_2d = build_sim(

sim_mode="sweep",

sim_dim="2D",

no=n_o,

ne=n_e,

nc=n_c,

src_pos=src_pos,

R=r_i,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=etch_d,

)

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(10, 3.0))

sim_3d.plot(z=h_dev / 2 - etch_d / 2, ax=ax1)

ax1.set_title("3D")

sim_2d.plot(y=0, ax=ax2)

ax2.set_aspect("auto")

ax2.set_title("2D")

plt.show()

Definition of Grating Coupler Structure#

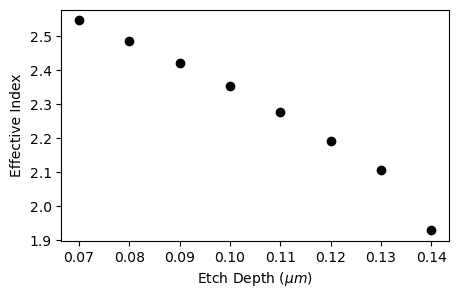

Now, we will vary the GC etch depth and the apodization parameter to maximize the coupling efficiency (CE). At each iteration, a source position sweep is performed to find the maximum CE, so totalizing len(etch_d_vals)\(\times\)len(R_vals)\(\times\)len(src_pos_vals) simulations.

[9]:

etch_d_vals = np.linspace(0.07, 0.14, 8)

R_vals = np.linspace(0.015, 0.035, 6)

src_pos_vals = np.linspace(4.0, 6.0, 5)

print(f"Number of simulations: {len(etch_d_vals)*len(R_vals)*len(src_pos_vals):d}")

Number of simulations: 240

As expected, the effective index decays as the etch depth increases.

[10]:

n_e_vals = np.zeros_like(etch_d_vals)

for i, ed in enumerate(etch_d_vals):

wg_e = waveguide.RectangularDielectric(

wavelength=wl,

core_width=2 * spot_size,

core_thickness=h_dev - ed,

core_medium=mat_si,

box_medium=mat_sio2,

clad_medium=mat_clad,

)

n_e_vals[i] = wg_e.n_eff.values[0, 0]

fig, ax = plt.subplots(1, figsize=(5, 3))

ax.plot(etch_d_vals, n_e_vals, "o", color="black")

ax.set_xlabel("Etch Depth ($\mu m$)")

ax.set_ylabel("Effective Index")

plt.show()

Next, we will build and run the parameter sweep using web.run_async. Verbosity will be turned off to reduce the amount of output data.

[11]:

sim_sweep = {

f"sim_etch_d:{ed}_R:{r}_src_pos:{sp}": build_sim(

sim_mode="sweep",

sim_dim="2D",

no=n_o,

ne=ne,

nc=n_c,

src_pos=sp,

R=r,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=ed,

)

for ed, ne in zip(etch_d_vals, n_e_vals)

for r in R_vals

for sp in src_pos_vals

}

batch_data = web.run_async(simulations=sim_sweep, path_dir="data", verbose=False)

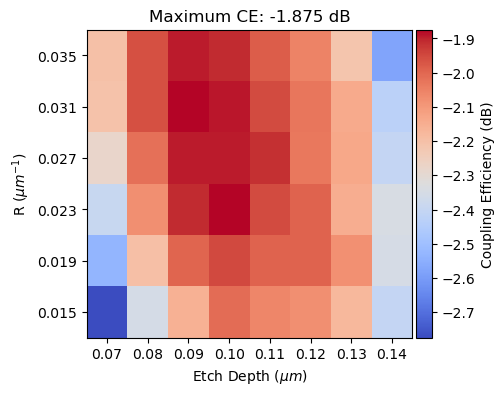

After completing batch simulation, we will calculate and analyze the data.

[12]:

ce_vals = np.ones((R_vals.size, etch_d_vals.size)) * (-1000)

src_vals = np.zeros_like(ce_vals)

for k, ed in enumerate(etch_d_vals):

for j, r in enumerate(R_vals):

for i, sp in enumerate(src_pos_vals):

sim_data = batch_data[f"sim_etch_d:{ed}_R:{r}_src_pos:{sp}"]

mode_amps = sim_data["mode_monitor"]

coeffs_f = mode_amps.amps.sel(direction="-")

power = np.abs(coeffs_f.sel(mode_index=0)) ** 2

power_db = np.asarray(np.amax(10 * np.log10(power)))

if ce_vals[j, k] < power_db:

ce_vals[j, k] = power_db

src_vals[j, k] = sp

A CE value of -1.9 dB is obtained for an etch depth of 0.09 \(\mu m\), R = 0.031 \(\mu^{-1}\), and the source positioned at 5 \(\mu m\). The next figure shows the higher values of CE with respect to etch depth and R.

[13]:

jr, ke = np.where(ce_vals == ce_vals.max())

final_etch_d = etch_d_vals[ke][0]

final_R = R_vals[jr][0]

final_src_pos = src_vals[jr, ke][0]

ce_2d = ce_vals[jr, ke][0]

print(f"Etch depth: {final_etch_d:.3f}")

print(f"R: {final_R:.3f}")

print(f"Source position: {final_src_pos:.3f}")

fig, ax = plt.subplots(1, figsize=(5, 4))

pcm = ax.pcolormesh(

etch_d_vals,

R_vals,

ce_vals,

shading="nearest",

cmap="coolwarm",

vmin=np.amin(ce_vals),

vmax=np.amax(ce_vals),

)

ax.set_xticks(etch_d_vals)

ax.set_yticks(R_vals)

ax.set_title(f"Maximum CE: {ce_2d:.3f} dB")

ax.set_xlabel("Etch Depth ($\mu m$)")

ax.set_ylabel("R ($\mu m^{-1}$)")

fig.colorbar(pcm, ax=ax, label="Coupling Efficiency (dB)", pad=0.01)

plt.show()

Etch depth: 0.090

R: 0.031

Source position: 5.000

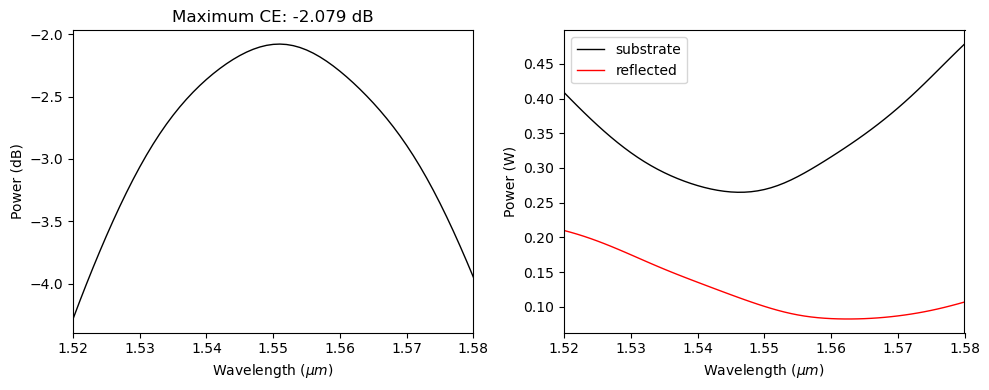

Final Grating Coupler Response#

Based on the parameters obtained in the previous section, we will build a 3D GC structure and calculate its response. A GDS file with the final layout will be output to gc_file.

[14]:

sim_3d = build_sim(

sim_mode="visualization",

sim_dim="3D",

no=n_o,

ne=n_e_vals[ke].item(),

nc=n_c,

src_pos=final_src_pos,

R=final_R,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=final_etch_d,

gds_file=gc_file,

)

fig, (ax1, ax2) = plt.subplots(1, 2, figsize=(10, 3.0))

sim_3d.plot(z=h_dev / 2 - etch_d / 2, ax=ax1)

sim_3d.plot(y=0, ax=ax2)

plt.show()

[15]:

job = web.Job(simulation=sim_3d, task_name="gc_in_coupling_3d", verbose=False)

sim_3d_in = job.run(path="data/gc3d_in_data.hdf5")

The CE of the 3D GC is lower than the 2D GC version only by 0.2 dB. The larger source of loss is the transmitted power into the silicon substrate.

[16]:

# Coupling Efficiency

mode_amps = sim_3d_in["mode_monitor"]

coeffs_f = mode_amps.amps.sel(direction="-")

power = np.abs(coeffs_f.sel(mode_index=0)) ** 2

power_db = 10 * np.log10(power)

ce_3d = np.amax(power_db)

# Fluxes

power_sub = abs(sim_3d_in["flux_sub"].flux)

power_ref = abs(sim_3d_in["flux_reflected"].flux)

fig, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

ax1.plot(wl_range, power_db, color="black", linestyle="solid", linewidth=1.0)

ax1.set_xlim([wl_range[0], wl_range[-1]])

ax1.set_xlabel("Wavelength ($\mu m$)")

ax1.set_ylabel("Power (dB)")

ax1.set_title(f"Maximum CE: {ce_3d:.3f} dB")

ax2.plot(

wl_range,

power_sub,

color="black",

linestyle="solid",

linewidth=1.0,

label="substrate",

)

ax2.plot(

wl_range,

power_ref,

color="red",

linestyle="solid",

linewidth=1.0,

label="reflected",

)

ax2.set_xlim([wl_range[0], wl_range[-1]])

ax2.set_xlabel("Wavelength ($\mu m$)")

ax2.set_ylabel("Power (W)")

ax2.legend()

plt.show()

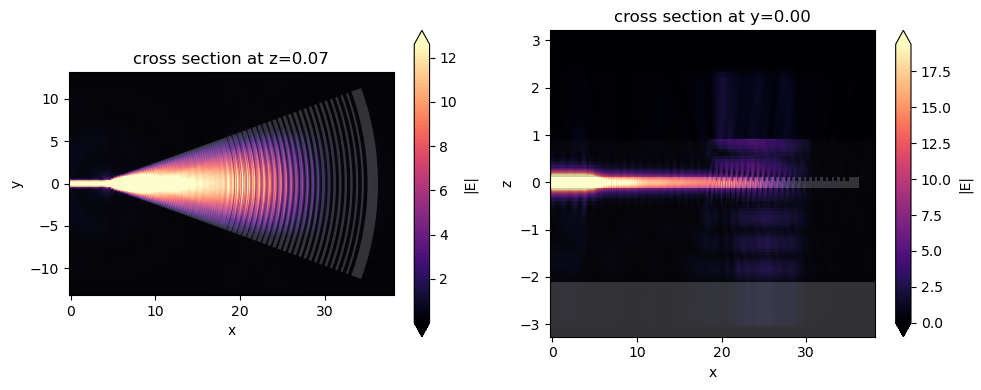

[17]:

fig, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

sim_3d_in.plot_field("field_xy", "E", f=freq, val="abs", ax=ax1)

sim_3d_in.plot_field("field_xz", "E", f=freq, val="abs", ax=ax2)

ax2.set_aspect("auto")

plt.show()

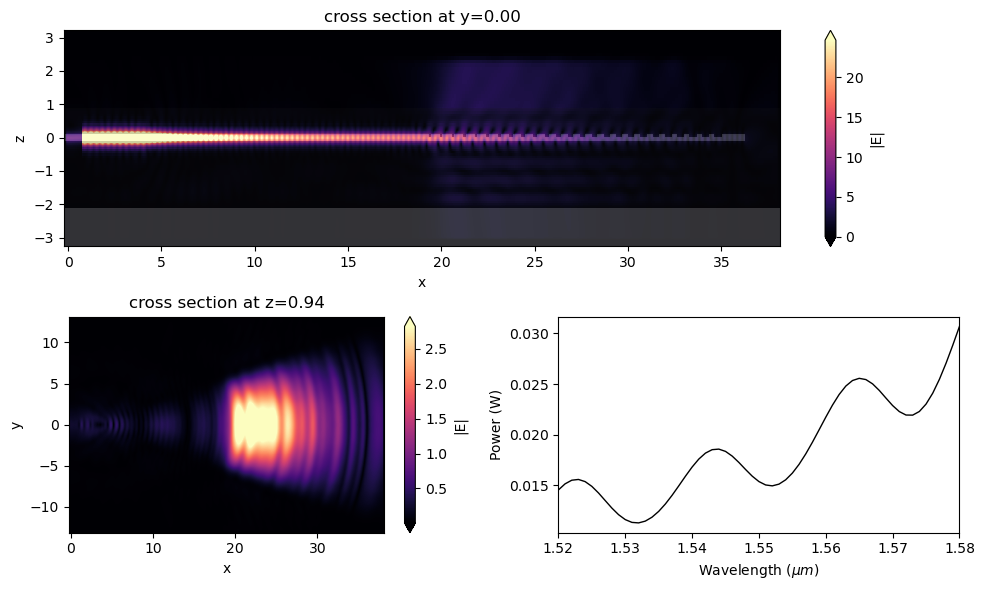

Out-coupling Configuration#

After obtaining the in-coupling response, we will build the same GC structure using the out-coupling configuration and run a final simulation.

[18]:

sim_3d_o = build_sim(

sim_mode="out_coupling",

sim_dim="3D",

no=n_o,

ne=n_e_vals[ke].item(),

nc=n_c,

src_pos=final_src_pos,

R=final_R,

alpha_t=alpha_t,

tap_l=tap_l,

tap_e=tap_e,

etch_d=final_etch_d,

gds_file=gc_file,

)

job = web.Job(simulation=sim_3d_o, task_name="gc_out_coupling_3d", verbose=False)

sim_3d_out = job.run(path="data/gc3d_out_data.hdf5")

First, let’s visualize the field at the \(xz\) plane and above the GC cladding layer. As one can see, most of the power is scattered upwards. This fact and the lower values of back reflections confirm the effectiveness of the apodization method in improving the GC efficiency.

[19]:

power_back = abs(sim_3d_out["flux_back"].flux)

fig = plt.figure(tight_layout=True, figsize=(10, 6))

gs = fig.add_gridspec(2, 2)

ax1 = fig.add_subplot(gs[0, :])

ax2 = fig.add_subplot(gs[1, 0])

ax3 = fig.add_subplot(gs[1, 1])

sim_3d_out.plot_field("field_xz", "E", f=freq, val="abs", ax=ax1)

ax1.set_aspect("auto")

sim_3d_out.plot_field("near_field", "E", f=freq, val="abs", ax=ax2)

ax3.plot(wl_range, power_back, color="black", linestyle="solid", linewidth=1.0)

ax3.set_xlim([wl_range[0], wl_range[-1]])

ax3.set_xlabel("Wavelength ($\mu m$)")

ax3.set_ylabel("Power (W)")

plt.show()

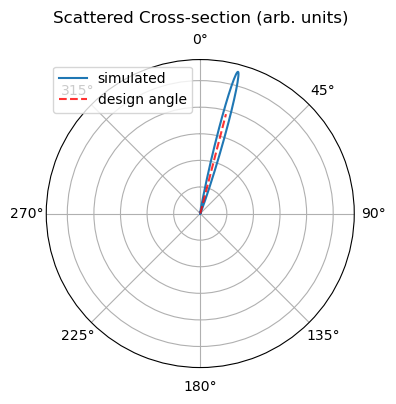

Finally, we will use the Tidy3D’s FieldProjector to compute the angular dependence of the far field scattering based on the near field monitor. The same approach presented and detailed in the uniform grating coupler notebook is used here.

[20]:

# Creates a range of angles to probe.

num_angles = 1101

thetas = np.linspace(-np.pi / 2, np.pi / 2, num_angles)

# Make a near-to-far monitor specifying the observation angles and frequencies of interest.

monitor_n2f = td.FieldProjectionAngleMonitor(

center=sim_3d_o.monitors[0].center,

size=sim_3d_o.monitors[0].size,

normal_dir="+",

freqs=[freq],

theta=thetas,

phi=[0.0],

name="n2f",

)

# Make a near field to far field projector with the near field monitor data

near_field_surface = td.FieldProjectionSurface(

monitor=sim_3d_o.monitors[0], normal_dir="+"

)

n2f = td.FieldProjector(sim_data=sim_3d_out, surfaces=[near_field_surface])

# Compute the far_fields

far_fields = n2f.project_fields(monitor_n2f)

# Compute the scattered cross section

ps = np.abs(far_fields.radar_cross_section.sel(f=freq).values[0, ...])

17:03:17 Eastern Standard Time WARNING: Colocating data that has already been colocated during the solver run. For most accurate results when colocating to custom coordinates set 'Monitor.colocate' to 'False' to use the raw data on the Yee grid and avoid double interpolation. Note: the default value was changed to 'True' in Tidy3D version 2.4.0.

A remarkable agreement between the target angle and the GC emission angle is obtained.

[21]:

# plot the angle dependence

fig, ax = plt.subplots(subplot_kw={"projection": "polar"}, figsize=(4, 4))

ax.plot(thetas, ps, label="simulated")

ax.plot(

[theta_f * np.pi / 180, theta_f * np.pi / 180],

[0, np.max(ps) * 0.7],

"r--",

alpha=0.8,

label="design angle",

)

ax.set_theta_zero_location("N")

ax.set_theta_direction(-1)

ax.set_yticklabels([])

ax.set_title("Scattered Cross-section (arb. units)", va="bottom")

plt.legend()

plt.show()