Strip to slot waveguide converters#

A strip waveguide is the most common integrated photonic waveguide that consists of a higher refractive index medium surrounded by a lower refractive index medium. The strip waveguide supports transverse electric (TE) and transverse magnetic (TM) modes of light propagation. On the other hand, a slot waveguide is a type of optical waveguide that consists of two strips of higher refractive index medium separated by a slot of lower refractive index medium. The slot waveguide supports only TE mode of light propagation. The unique property of the slot waveguide is the ability to confine light in the low refractive index region, which can be used to enhance light-matter interaction.

A strip-to-slot waveguide converter is a device that is used to convert the mode of light propagation from a strip waveguide mode to a slot waveguide mode. The converter is designed in such a way that the conversion is efficient and with minimal loss of light. The strip-to-slot waveguide converter is an important component in integrated photonic circuits, enabling the use of different waveguide configurations for different functionalities within the same circuit.

In this notebook, we demonstrate three different converter designs and compare their pros and cons. The strip waveguide has a width of 400 nm. The slot waveguide has a width of 620 nm with a 100 nm slot width. Both waveguides are fabricated on 250 nm silicon on insulator with oxide top cladding.

[1]:

import numpy as np

import matplotlib.pyplot as plt

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins import waveguide

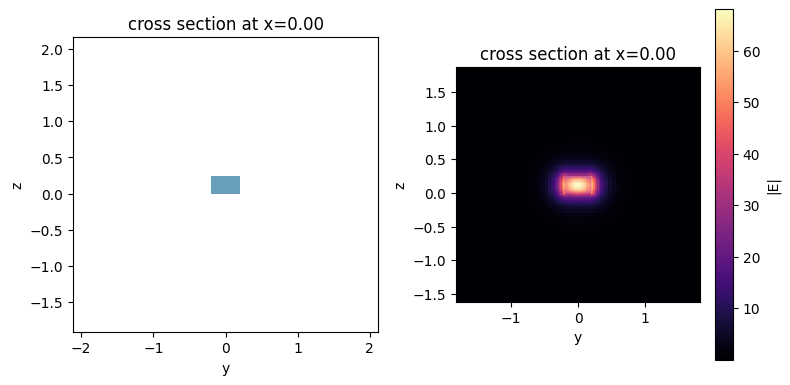

Visualizing the Strip and Slot Modes#

Before any simulation, we can use the waveguide plugin to study the strip and slot waveguide modes.

Define the simulation wavelength and frequency ranges.

[2]:

lda0 = 1.55 # central wavelength

ldas = np.linspace(1.5, 1.6, 101) # wavelength range of interest

freq0 = td.C_0 / lda0 # central frequency

freqs = td.C_0 / ldas # frequency range of interest

fwidth = 0.5 * (np.max(freqs) - np.min(freqs)) # frequency width of the source

Define the geometric parameters of the waveguides.

[3]:

h_si = 0.25 # thickness of the silicon layer

w_strip = 0.4 # width of the strip waveguide

w_slot = 0.62 # width of the slot waveguide

g = 0.1 # width of the slot

Define material properties.

[4]:

n_si = 3.47 # silicon refractive index

si = td.Medium(permittivity=n_si**2)

n_sio2 = 1.44 # silicon oxide refractive index

sio2 = td.Medium(permittivity=n_sio2**2)

We use the waveguide plugin to visualize the strip mode profile.

[5]:

strip = waveguide.RectangularDielectric(

wavelength=lda0,

core_width=w_strip,

core_thickness=h_si,

core_medium=si,

clad_medium=sio2,

mode_spec=td.ModeSpec(num_modes=1),

)

fig, ax = plt.subplots(1, 2, figsize=(8, 4), tight_layout=True)

strip.plot_structures(x=0, ax=ax[0])

strip.plot_field("E", val="abs", ax=ax[1], robust=False)

Similarly, we visualize the slot mode profile. As expected, the mode concentrates inside the slot.

[6]:

slot = waveguide.RectangularDielectric(

wavelength=lda0,

core_width=((w_slot - g) / 2, (w_slot - g) / 2),

core_thickness=h_si,

core_medium=si,

clad_medium=sio2,

gap=g,

mode_spec=td.ModeSpec(num_modes=1),

)

fig, ax = plt.subplots(1, 2, figsize=(8, 4), tight_layout=True)

slot.plot_structures(x=0, ax=ax[0])

# We use 'robust=False' because we're interested in the large values at the slot

slot.plot_field("E", val="abs", ax=ax[1], robust=False)

Besides visualizing the mode profiles, the waveguide plugin also provides many other functionalities such as calculating the effective indices and mode volume to help with extensive mode analysis. For detail, please refer to the waveguide plugin tutorial.

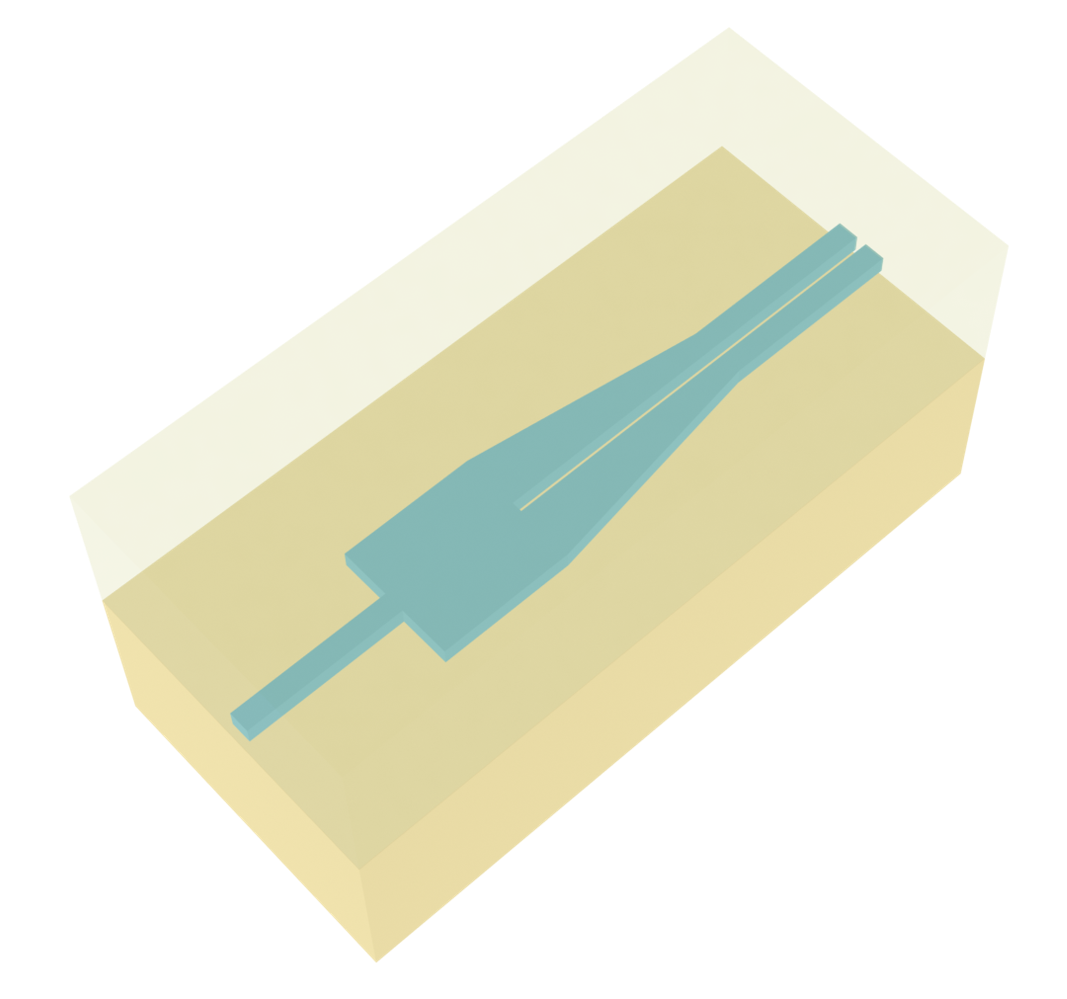

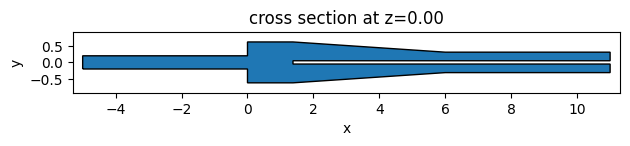

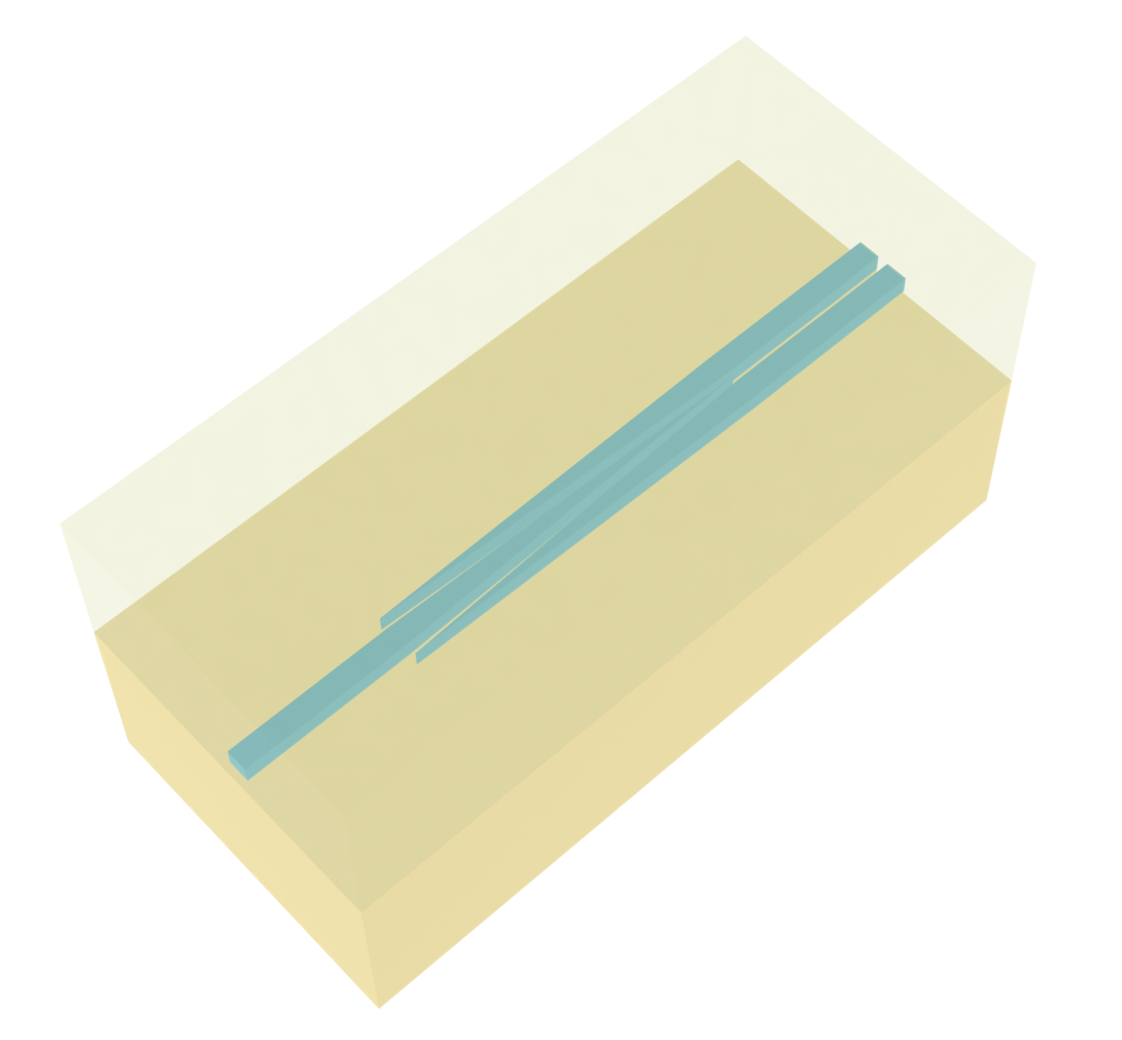

Design 1#

The first converter design is based on symmetric multimode interference as introduced in Qingzhong Deng, Lu Liu, Xinbai Li, and Zhiping Zhou, "Strip-slot waveguide mode converter based on symmetric multimode interference," Opt. Lett. 39, 5665-5668 (2014)DOI: 10.1364/OL.39.005665. In this design, the footprint of the converter is compact (~ 6 \(\mu m\)) and it does not contain pointy parts that are hard to fabricate. The achievable coupling

efficiency is above 95% in the entire C band.

Define geometric parameters of the device.

[7]:

L_mmi = 1.38 # length of the MMI section

W_mmi = 1.24 # width of the MMI section

L = 6 # length of the taper

buffer = 5 # buffer spacing before and after the converter

The converter designs in this notebook do not contain bending parts. Therefore, the easiest way to define the geometries is by using PolySlabs. The coordinates of the vertices can be easily calculated using the geometric parameters defined above.

[8]:

# define the poly slab vertices

vertices = [

(-buffer, w_strip / 2),

(0, w_strip / 2),

(0, W_mmi / 2),

(L_mmi, W_mmi / 2),

(L, w_slot / 2),

(L + buffer, w_slot / 2),

(L + buffer, g / 2),

(L_mmi, g / 2),

(L_mmi, -g / 2),

(L + buffer, -g / 2),

(L + buffer, -w_slot / 2),

(L, -w_slot / 2),

(L_mmi, -W_mmi / 2),

(0, -W_mmi / 2),

(0, -w_strip / 2),

(-buffer, -w_strip / 2),

]

# define the converter structure

converter = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

# plot the structure for visualization

converter.plot(z=0)

plt.show()

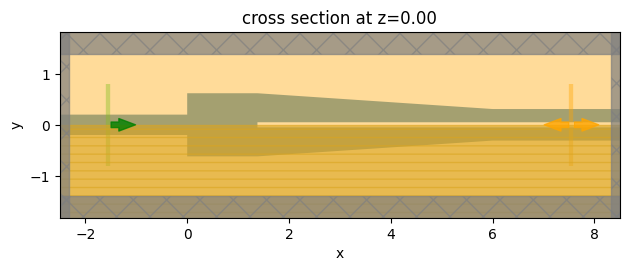

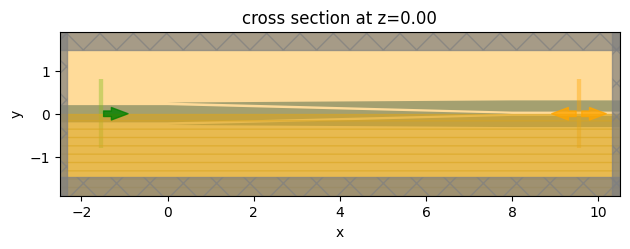

We will use a ModeSource to excite the strip waveguide using the fundamental TE mode. Note that we use num_freqs=7 Chebyshev nodes to approximate mode frequency dependency in [freq0 - 1.5 * fwidth, freq0 + 1.5 * fwidth] for an accurate broadband simulation.

A ModeMonitor is placed at the slot waveguide to measure the coupling efficiency. A FieldMonitor is added to the \(xy\) plane to visualize the field distribution.

[9]:

# add a mode source to launch the TE0 mode at the strip waveguide before the converter

mode_spec = td.ModeSpec(num_modes=1, target_neff=n_si)

mode_source = td.ModeSource(

center=(-lda0, 0, 0),

size=(0, 4 * w_strip, 6 * h_si),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=mode_spec,

mode_index=0,

num_freqs=7,

)

# add a mode monitor to measure transmission at the slot waveguide after the converter

mode_monitor = td.ModeMonitor(

center=(L + lda0, 0, 0),

size=(0, 4 * w_strip, 6 * h_si),

freqs=freqs,

mode_spec=mode_spec,

name="mode",

)

# add a field monitor to visualize field distribution at z=0

field_monitor = td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

[16:45:47] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

Set up the Simulation with the previously defined Structure, source, and monitors. All boundaries are set to PML to mimic infinite open space. Since the top and bottom claddings are silicon oxide, we will set the medium of the background to silicon oxide. Due to the symmetry of the device and the

modes, we utilize symmetry=(0,-1,1) to reduce the computational cost to a quarter. For such a small simulation domain, we can afford to use a very fine grid.

[10]:

Lx = L + 3 * lda0 # simulation domain size in x direction

Ly = W_mmi + lda0 # simulation domain size in y direction

Lz = 10 * h_si # simulation domain size in z direction

sim_size = (Lx, Ly, Lz)

run_time = 1e-12 # simulation run time

# construct simulation

sim_1 = td.Simulation(

center=(L / 2, 0, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=30, wavelength=lda0),

structures=[converter],

sources=[mode_source],

monitors=[mode_monitor, field_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

symmetry=(0, -1, 1),

)

# plot the simulation

sim_1.plot(z=0)

plt.show()

Submit the simulation to the server to run.

[11]:

sim_data_1 = web.run(

simulation=sim_1, task_name="strip_to_slot_converter_1", path="data/simulation_data.hdf5"

)

[16:45:48] View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- b58b4c07-f06f-4b47-96c0-2aa913551d0cv1'.

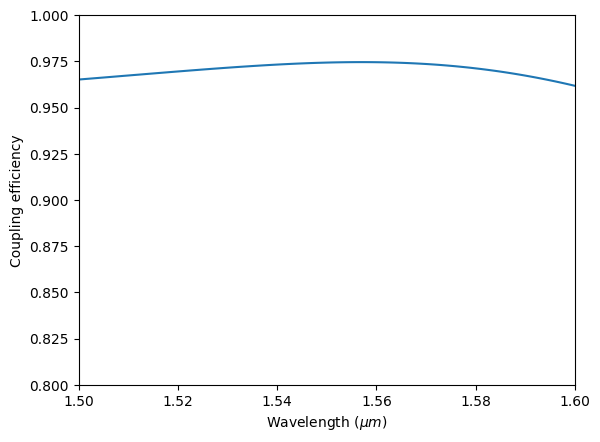

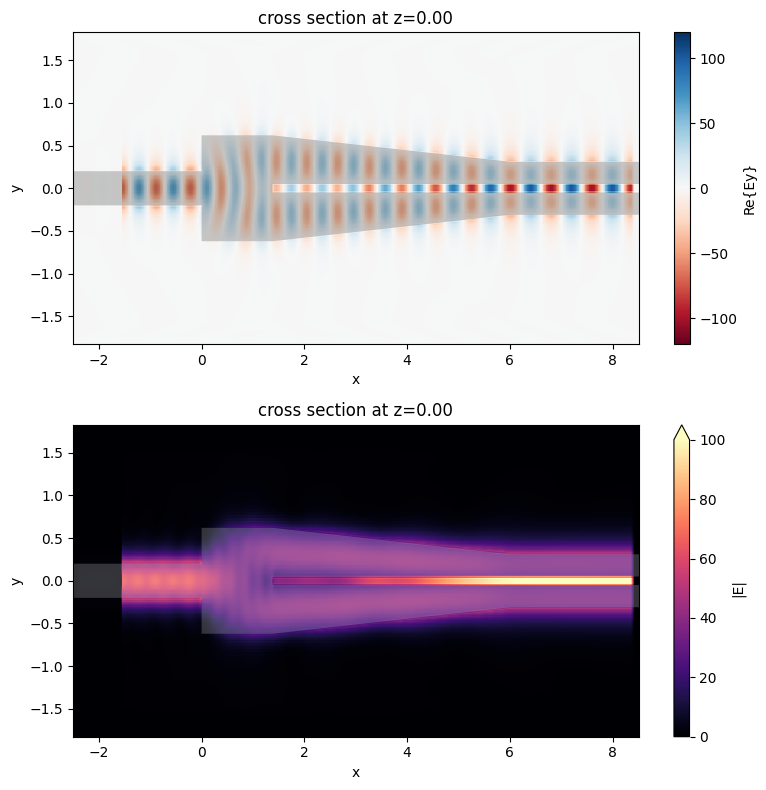

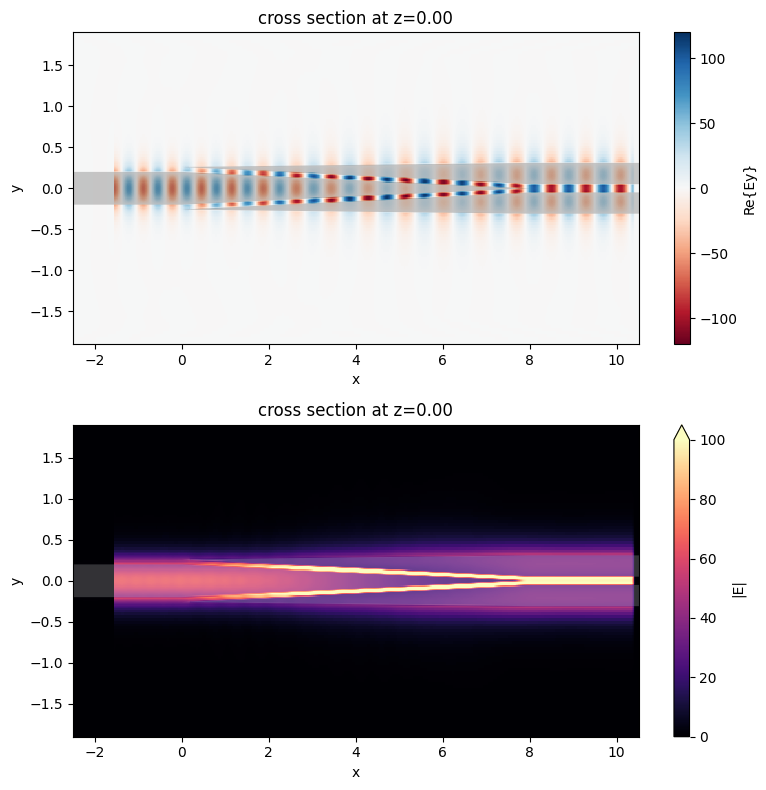

We define two postprocessing functions plot_convertion_efficiency and plot_field to plot the coupling efficiency of the converter as well as the field distributions.

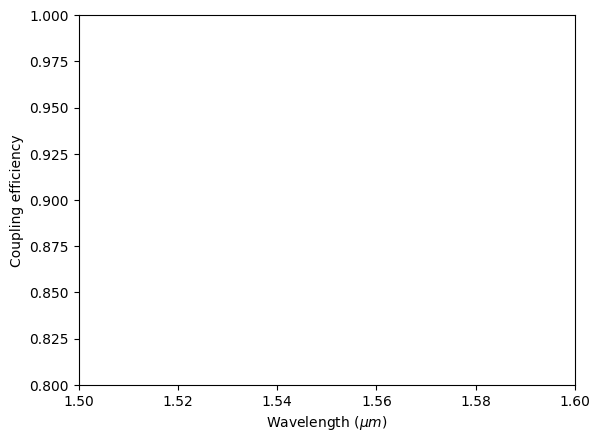

For this design, we see a coupling efficiency above 95%.

[12]:

def plot_convertion_efficiency(sim_data):

# extract the convertion efficiency from the mode monitor

amp = sim_data["mode"].amps.sel(mode_index=0, direction="+")

T = np.abs(amp) ** 2

# plot the coupling efficiency

plt.plot(ldas, T)

plt.xlim(1.5, 1.6)

plt.ylim(0.8, 1)

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Coupling efficiency")

plt.show()

plot_convertion_efficiency(sim_data_1)

[13]:

def plot_field(sim_data):

fig, (ax1, ax2) = plt.subplots(2, 1, figsize=(8, 8), tight_layout=True)

sim_data.plot_field(

field_monitor_name="field",

field_name="Ey",

val="real",

f=freq0,

vmin=-120,

vmax=120,

ax=ax1,

)

ax1.set_aspect("auto")

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs", f=freq0, vmin=0, vmax=100, ax=ax2

)

ax2.set_aspect("auto")

plt.show()

plot_field(sim_data_1)

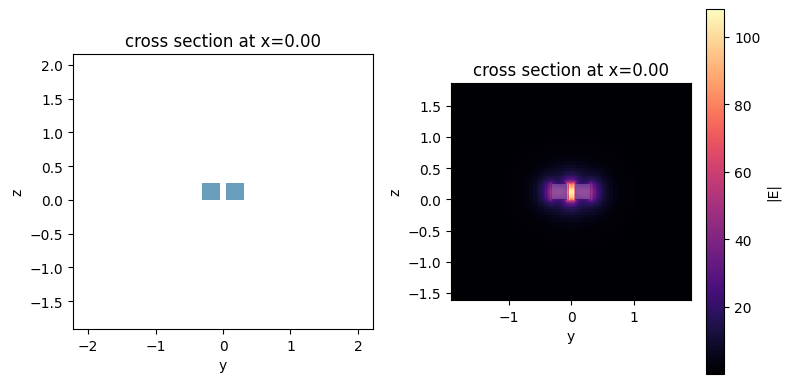

Design 2#

The second design of the strip to slot waveguide converter is based on symmetry linear tapers as introduced in Zhechao Wang, Ning Zhu, Yongbo Tang, Lech Wosinski, Daoxin Dai, and Sailing He, "Ultracompact low-loss coupler between strip and slot waveguides," Opt. Lett. 34, 1498-1500 (2009)DOI: 10.1364/OL.34.001498. This design is compact (~ 8\(\mu m\)) and can achieve nearly 100% coupling efficiency. However, it contains smaller features

associated with the tips of the tapers. In practice, fabrication tolerance can degrade the device performance.

To define the structures of this converter, again we use a similar approach by defining the vertices and constructing PolySlabs. This device contains three separate structures, which we name strip_taper, slot_top, and slot_bottom.

[14]:

L_taper = 8 # length of the taper

d = 0.06 # distance between the taper end and the strip

vertices = [

(-buffer, w_strip / 2),

(0, w_strip / 2),

(L_taper, 0),

(0, -w_strip / 2),

(-buffer, -w_strip / 2),

]

strip_taper = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

vertices = [

(0, w_strip / 2 + d),

(L_taper, w_slot / 2),

(L_taper + buffer, w_slot / 2),

(L_taper + buffer, g / 2),

(L_taper, g / 2),

]

slot_top = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

vertices = [

(0, -w_strip / 2 - d),

(L_taper, -w_slot / 2),

(L_taper + buffer, -w_slot / 2),

(L_taper + buffer, -g / 2),

(L_taper, -g / 2),

]

slot_bottom = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

The overall setup of this simulation is very similar to the previous one so we can reuse many previously defined objects. However, we need to adjust the ModeMonitor position, which can be done conveniently by copying the previous ModeMonitor and only updating its center position.

[15]:

# add a mode monitor to measure transmission at the output waveguide

mode_monitor = mode_monitor.copy(update={"center": (L_taper + lda0, 0, 0)})

Lx = L_taper + 3 * lda0 # simulation domain size in x direction

Ly = w_slot + 1.5 * lda0 # simulation domain size in y direction

sim_size = (Lx, Ly, Lz)

# construct simulation

sim_2 = td.Simulation(

center=(L_taper / 2, 0, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=30, wavelength=lda0),

structures=[strip_taper, slot_top, slot_bottom],

sources=[mode_source],

monitors=[mode_monitor, field_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

symmetry=(0, -1, 1),

)

sim_2.plot(z=0)

plt.show()

Submit the simulation to the server to run.

[16]:

sim_data_2 = web.run(

simulation=sim_2, task_name="strip_to_slot_converter_2", path="data/simulation_data.hdf5"

)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- b8880ed6-d769-4735-ba06-7f5f8dcd61f6v1'.

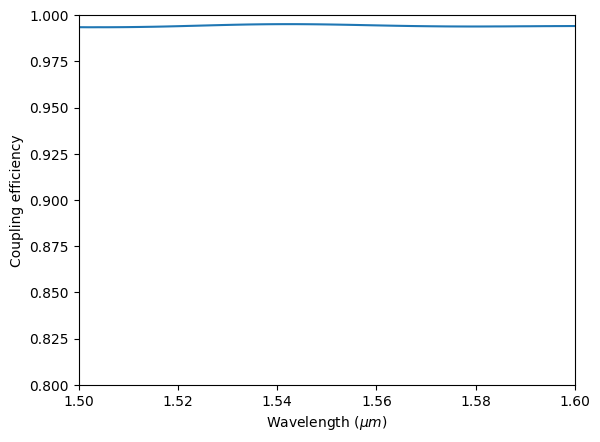

Apply the same postprocessing to the simulation result. In this design, nearly 100% coupling efficiency can be achieved in the ideal case.

[17]:

plot_convertion_efficiency(sim_data_2)

[18]:

plot_field(sim_data_2)

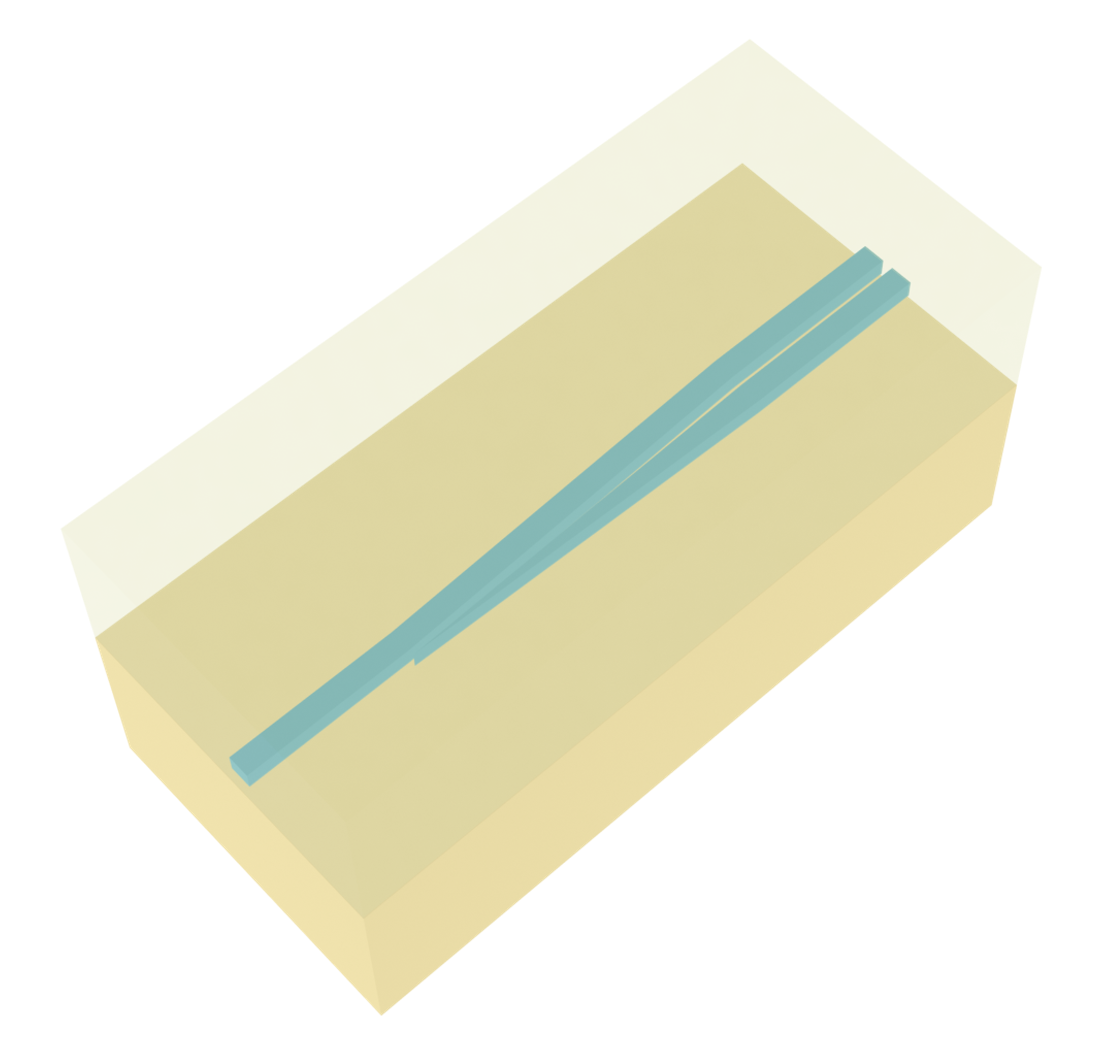

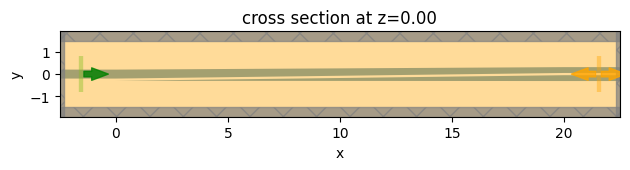

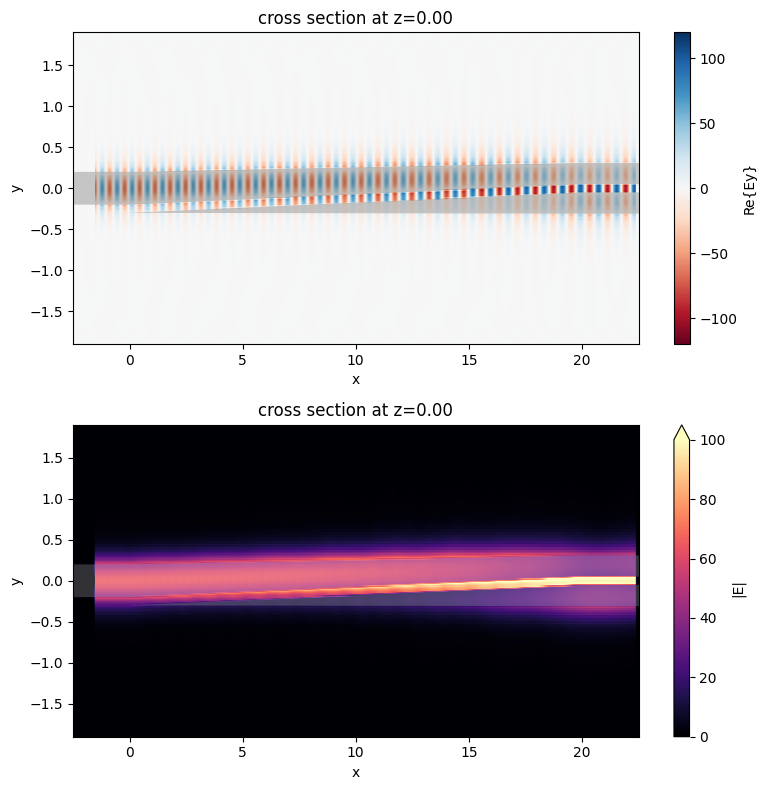

Design 3#

The last design is based on asymmetric linear taper as introduced in Ning-Ning Feng, Rong Sun, Lionel C. Kimerling, and Jurgen Michel, "Lossless strip-to-slot waveguide transformer," Opt. Lett. 32, 1250-1252 (2007)DOI: 10.1364/OL.32.001250. This design is the most straightforward while the footprint is relatively large and it contains small features that are difficult to fabricate. In the ideal case as simulated here, the coupling efficiency can

also be close to 100%.

Again, the process of setting up the simulation is similar to the previous two. Note that for this device, we can only use symmetry=(0,0,1) since there is no symmetry in the \(y\) direction.

[19]:

L = 20 # length of the converter region

vertices = [

(-buffer, w_strip / 2),

(0, w_strip / 2),

(L, w_slot / 2),

(L + buffer, w_slot / 2),

(L + buffer, g / 2),

(L, g / 2),

(0, -w_strip / 2),

(-buffer, -w_strip / 2),

]

converter_top = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

vertices = [

(0, -w_strip / 2 - g),

(L, -g / 2),

(L + buffer, -g / 2),

(L + buffer, -w_slot / 2),

(L, -w_slot / 2),

]

converter_bottom = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(-h_si / 2, h_si / 2)), medium=si

)

[20]:

mode_monitor = mode_monitor.copy(update={"center": (L + lda0, 0, 0)})

Lx = L + 3 * lda0 # simulation domain size in x direction

sim_size = (Lx, Ly, Lz)

# construct simulation

sim_3 = td.Simulation(

center=(L / 2, 0, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=30, wavelength=lda0),

structures=[converter_top, converter_bottom],

sources=[mode_source],

monitors=[mode_monitor, field_monitor],

run_time=run_time,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

symmetry=(0, 0, 1),

)

sim_3.plot(z=0)

plt.show()

[21]:

sim_data_3 = web.run(

simulation=sim_3, task_name="strip_to_slot_converter_3", path="data/simulation_data.hdf5"

)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 61bcf001-c73c-4c28-a749-3dc0119f6808v1'.

The convertion efficiency is also close to 100%.

[22]:

plot_convertion_efficiency(sim_data_3)

[23]:

plot_field(sim_data_3)

Closing Remark#

Different designs of the converters have their advantages and disadvantages. The choice of the design should be based on fabrication capability, constraints on device footprint, and the required coupling efficiency. In this notebook, we only simulated the ideal designs. To be more practical, simulations that consider the fabrication constraints need to be performed. As introduced in the referenced papers, the pointy tips of the tapers will have a finite width due to the finite fabrication resolution. Simulations with more realistic device geometry will be extremely useful for design and testing.

In addition, the design parameters used in this notebook are optimized for the specific waveguide widths, thickness, and materials. For a different plateform, the parameters need to be re-optmized, which can be done using the adjoint method as provided in Tidy3D’s adjoint plugin. Users follow a similar procedure as introduced in the tutorial of optimizing a waveguide taper.

[ ]: