1x4 MMI power splitter#

Note: the cost of running the entire notebook is larger than 1 FlexCredit.

Optical power splitters are essential components in integrated photonics. Power splitters based on multimode interference (MMI) device are easy to fabricate and can achieve low excess loss as well as large bandwidth. Although the design of a MMI power splitter is based on the self-imaging principle, fine-tuning the geometric parameters with accurate and fast numerical simulations is crucial to achieving optimal device performance.

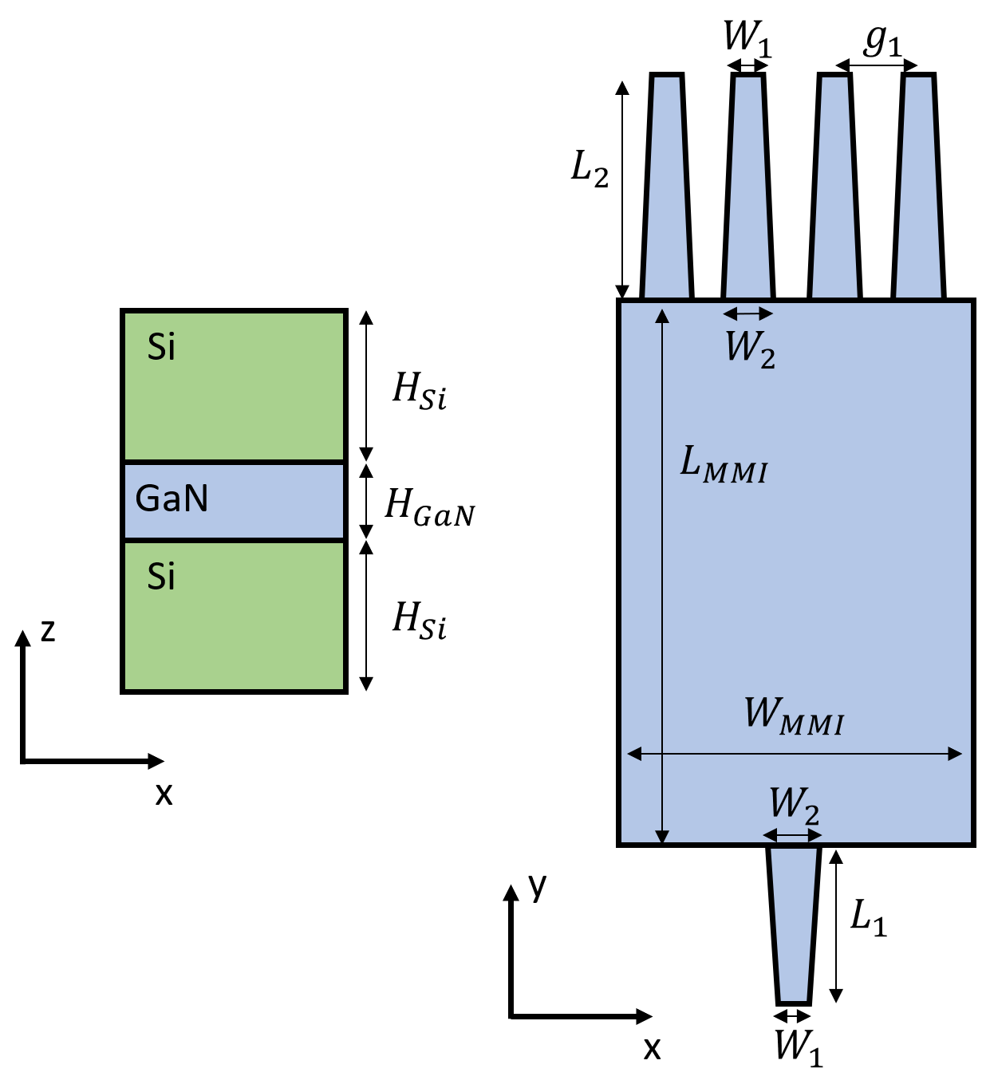

This example aims to demonstrate the design and optimization of 1 to 4 MMI device at telecom wavelength for power splitting applications. The initial design is adapted from D. Malka, Y. Danan, Y. Ramon, Z. Zalevsky, A Photonic 1 x 4 Power Splitter Based on Multimode Interference in Silicon–Gallium-Nitride Slot Waveguide Structures. Materials. 9, 516 (2016).

The device uses a Si-GaN-Si slot waveguide strcuture as schematically shown below.

For more integrated photonic examples such as the 8-Channel mode and polarization de-multiplexer, the broadband bi-level taper polarization rotator-splitter, and the broadband directional coupler, please visit our examples page.

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials.

Simulation Setup#

[1]:

import numpy as np

import matplotlib.pyplot as plt

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins.mode import ModeSolver

Define materials. There are three materials involved in this model. The SiO2 cladding and the Si waveguide with GaN slot. All materials are modeled as lossless and dispersionless in this particular case.

[2]:

# material refractive indices

n_si = 3.48

n_gan = 2.305

n_sio2 = 1.444

# define media

si = td.Medium(permittivity=n_si**2)

gan = td.Medium(permittivity=n_gan**2)

sio2 = td.Medium(permittivity=n_sio2**2)

Define initial design parameters and wrap simulation setup in a function. The arguments of the function are the paremeters we want to optimize later. In this example, we aim to optimize the length and width of the MMI section.

[3]:

W_MMI = 5 # width of the MMI section

L_MMI = 11.2 # length of the MMI section

g1 = 0.9 # gap between the output waveguides

W1 = 0.4 # width of the waveguide

W2 = 0.8 # width of the tapper

L1 = 2 # length of the input tapper

L2 = 5 # length of the output tapper

H_Si = 0.3 # thickness of the Si layer

H_GaN = 0.1 # thickness of the GaN layer

g3 = (W2 - W1) / 2 # auxilary parameter defined for easier geometry building

g2 = g1 - 2 * g3 # gap between the output tapers

lda0 = 1.55 # central wavelength

freq0 = td.C_0 / lda0 # central frequency

ldas = np.linspace(1.5, 1.6, 101) # wavelength range

freqs = td.C_0 / ldas # frequency range

fwidth = 0.5 * (np.max(freqs) - np.min(freqs))

# buffer spacings in the x and y directions.

buffer_x = 1

buffer_y = 1.5

# define a function that takes the geometric parameters as input arguments and return a Simulation object

def make_sim(L_MMI, W_MMI):

# the whole device is defined as a PolySlab with vertices given by the following

vertices = np.array(

[

(-W1 / 2, -100),

(-W1 / 2, 0),

(-W2 / 2, L1),

(-W_MMI / 2, L1),

(-W_MMI / 2, L1 + L_MMI),

(-g2 / 2 - W2 - g2 - 2 * g3 - W1, L1 + L_MMI),

(-g2 / 2 - W2 - g2 - g3 - W1, L1 + L_MMI + L2),

(-g2 / 2 - W2 - g2 - g3 - W1, 100),

(-g2 / 2 - W2 - g2 - g3, 100),

(-g2 / 2 - W2 - g2 - g3, L1 + L_MMI + L2),

(-g2 / 2 - W2 - g2, L1 + L_MMI),

(-g2 / 2 - W2, L1 + L_MMI),

(-g1 / 2 - W1, L1 + L_MMI + L2),

(-g1 / 2 - W1, 100),

(-g1 / 2, 100),

(-g1 / 2, L1 + L_MMI + L2),

(-g2 / 2, L1 + L_MMI),

(g2 / 2, L1 + L_MMI),

(g1 / 2, L1 + L_MMI + L2),

(g1 / 2, 100),

(g1 / 2 + W1, 100),

(g1 / 2 + W1, L1 + L_MMI + L2),

(g2 / 2 + W2, L1 + L_MMI),

(g2 / 2 + W2 + g2, L1 + L_MMI),

(g2 / 2 + W2 + g2 + g3, L1 + L_MMI + L2),

(g1 / 2 + W1 + g1, 100),

(g1 / 2 + W1 + g1 + W1, 100),

(g2 / 2 + W2 + g2 + g3 + W1, L1 + L_MMI + L2),

(g2 / 2 + W2 + g2 + 2 * g3 + W1, L1 + L_MMI),

(W_MMI / 2, L1 + L_MMI),

(W_MMI / 2, L1),

(W2 / 2, L1),

(W1 / 2, 0),

(W1 / 2, -100),

]

)

mmi_layer1 = td.Structure(

geometry=td.PolySlab(

vertices=vertices,

axis=2,

slab_bounds=(-H_Si - 0.5 * H_GaN, H_Si + 0.5 * H_GaN),

),

medium=si,

)

mmi_layer2 = td.Structure(

geometry=td.PolySlab(

vertices=vertices, axis=2, slab_bounds=(-0.5 * H_GaN, 0.5 * H_GaN)

),

medium=gan,

)

# simulation domain size

Lx = W_MMI + 2 * buffer_x

Ly = L1 + L_MMI + L2 + 2 * buffer_y

Lz = 5 * (H_GaN * 2 + H_Si)

sim_size = (Lx, Ly, Lz)

mode_spec = td.ModeSpec(num_modes=2, target_neff=n_si)

# add a mode source for excitation

mode_source = td.ModeSource(

center=(0, -buffer_y / 3, 0),

size=(5 * W1, 0, Lz),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=mode_spec,

mode_index=0,

num_freqs=5,

)

# add two flux monitors to monitor the transmission power at output waveguides

flux_monitor1 = td.FluxMonitor(

center=((g1 + W1) / 2, Ly - buffer_y / 2, 0),

size=(3 * W1, 0, Lz),

freqs=freqs,

name="flux1",

)

flux_monitor2 = td.FluxMonitor(

center=(3 * (g1 + W1) / 2, Ly - buffer_y / 2, 0),

size=(3 * W1, 0, Lz),

freqs=freqs,

name="flux2",

)

# add two mode monitors to monitor the mode profiles at output waveguides

mode_monitor1 = td.ModeMonitor(

center=((g1 + W1) / 2, Ly - buffer_y / 2, 0),

size=(3 * W1, 0, Lz),

freqs=freqs,

mode_spec=mode_spec,

name="mode1",

)

mode_monitor2 = td.ModeMonitor(

center=(3 * (g1 + W1) / 2, Ly - buffer_y / 2, 0),

size=(3 * W1, 0, Lz),

freqs=freqs,

mode_spec=mode_spec,

name="mode2",

)

# add a field monitor to monitor the field distribution

field_monitor = td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

sim = td.Simulation(

center=(0, Ly / 2 - buffer_y / 2, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=20, wavelength=td.C_0 / freq0),

structures=[mmi_layer1, mmi_layer2],

sources=[mode_source],

monitors=[

field_monitor,

flux_monitor1,

flux_monitor2,

mode_monitor1,

mode_monitor2,

],

run_time=5e-12,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

symmetry=(1, 0, -1),

)

return sim

Initial Design#

First, we simulate an initial design using the previously defined design parameters.

[4]:

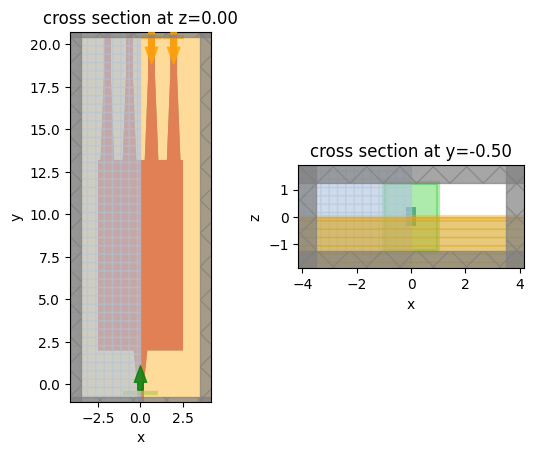

f, (ax1, ax2) = plt.subplots(1, 2)

sim = make_sim(L_MMI, W_MMI)

sim.plot(z=0, ax=ax1)

sim.plot(y=-buffer_y / 3, ax=ax2)

plt.show()

[13:11:00] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

Before simulation, let’s inspect the waveguide modes supported in the slot waveguide to make sure we are using the correct excitation source.

[5]:

mode_solver = ModeSolver(

simulation=sim,

plane=td.Box(center=sim.sources[0].center, size=sim.sources[0].size),

mode_spec=sim.sources[0].mode_spec,

freqs=[freq0],

)

mode_data = mode_solver.solve()

WARNING: Use the remote mode solver with subpixel mode_solver.py:141 averaging for better accuracy through 'tidy3d.plugins.mode.web.run(...)'.

The lowest order mode shows a strong field confinement between the Si area. This is the mode we want to use as excitation.

[6]:

mode_index = 0

f, (ax1, ax2, ax3) = plt.subplots(1, 3, tight_layout=True, figsize=(10, 3))

abs(mode_data.Ex.isel(mode_index=mode_index)).plot(x="x", y="z", ax=ax1, cmap="magma")

abs(mode_data.Ey.isel(mode_index=mode_index)).plot(x="x", y="z", ax=ax2, cmap="magma")

abs(mode_data.Ez.isel(mode_index=mode_index)).plot(x="x", y="z", ax=ax3, cmap="magma")

ax1.set_title("|Ex(x, y)|")

ax1.set_aspect("equal")

ax2.set_title("|Ey(x, y)|")

ax2.set_aspect("equal")

ax3.set_title("|Ez(x, y)|")

ax3.set_aspect("equal")

plt.show()

Submit simulation job to the server.

[7]:

job = web.Job(simulation=sim, task_name="mmi", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- e80a90ee-0702-4221-9545-8a6d1f1eb71dv1'.

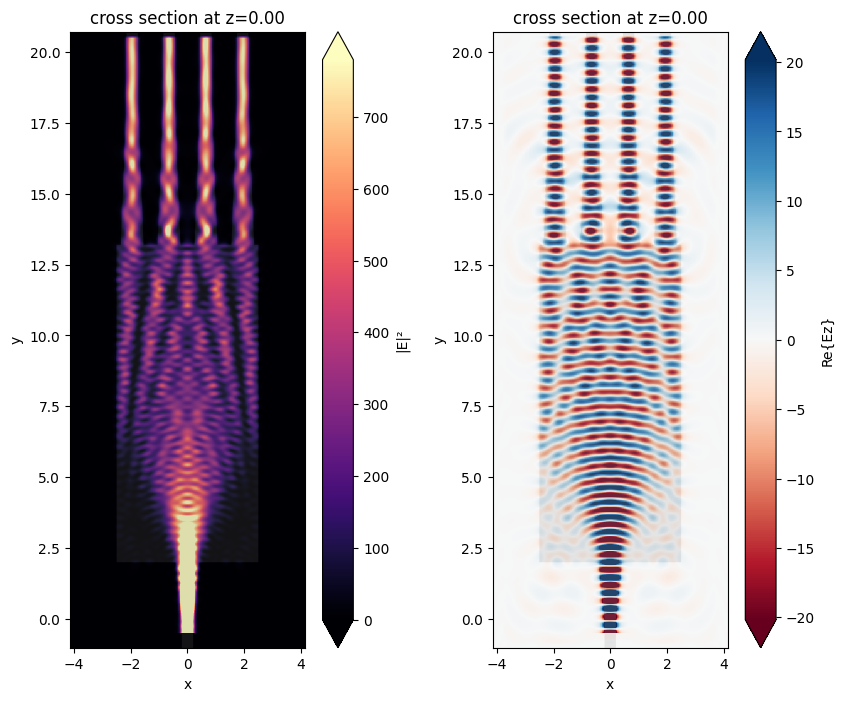

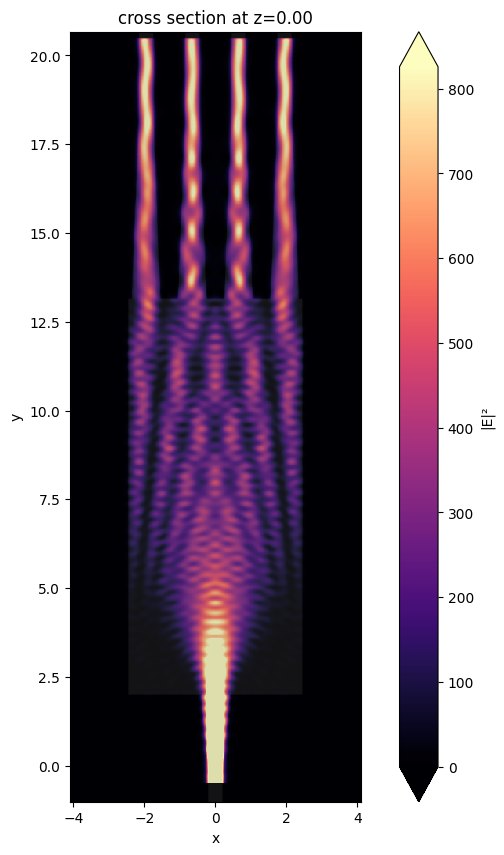

Visualize the field distribution.

[8]:

f, (ax1, ax2) = plt.subplots(1, 2, figsize=(10, 8))

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", ax=ax1, f=freq0

)

sim_data.plot_field(field_monitor_name="field", field_name="Ez", ax=ax2, f=freq0)

plt.show()

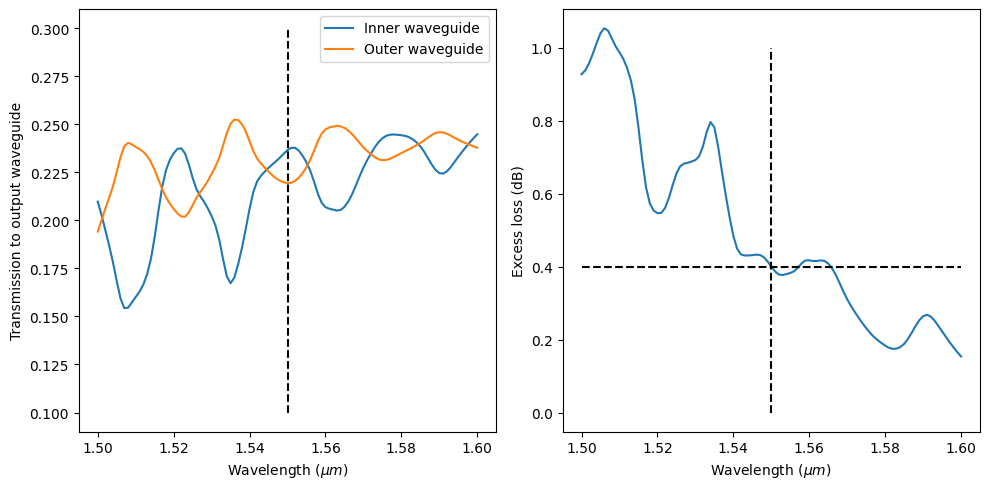

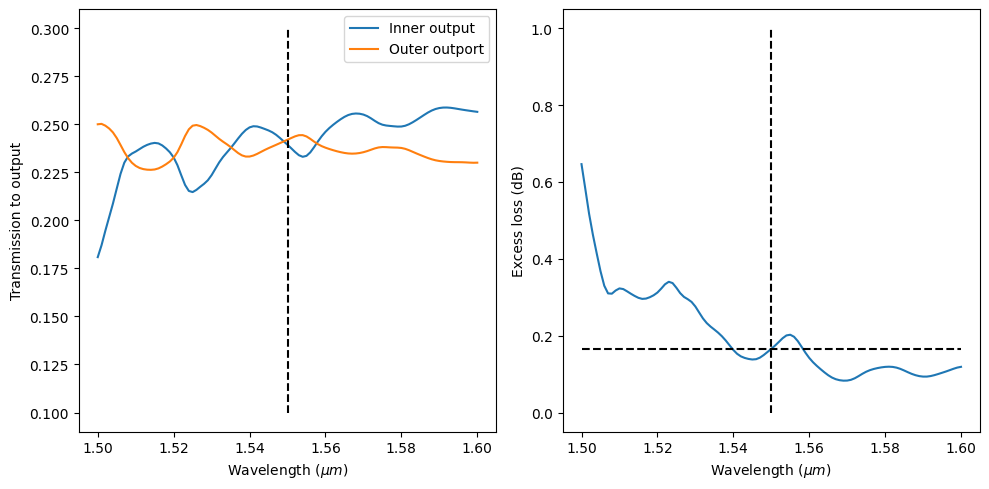

Plot transmission on each output waveguide as well as the total excess loss. At the central wavelength of 1550 nm, the transimission power at the inner waveguide and outer waveguide differs by about 2%. The excess loss is about 0.4 dB.

[9]:

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 5))

T1 = sim_data["flux1"].flux

T2 = sim_data["flux2"].flux

plt.sca(ax1)

plt.plot(ldas, T1, ldas, T2)

plt.vlines(x=1.55, ymin=0.1, ymax=0.3, colors="black", ls="--")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Transmission to output waveguide")

plt.legend(("Inner waveguide", "Outer waveguide"))

plt.sca(ax2)

excess_loss = -10 * np.log10(2 * (T1 + T2))

plt.plot(ldas, excess_loss)

plt.vlines(x=1.55, ymin=0, ymax=1, colors="black", ls="--")

plt.hlines(y=excess_loss[50], xmin=1.5, xmax=1.6, colors="black", ls="--")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Excess loss (dB)")

plt.show()

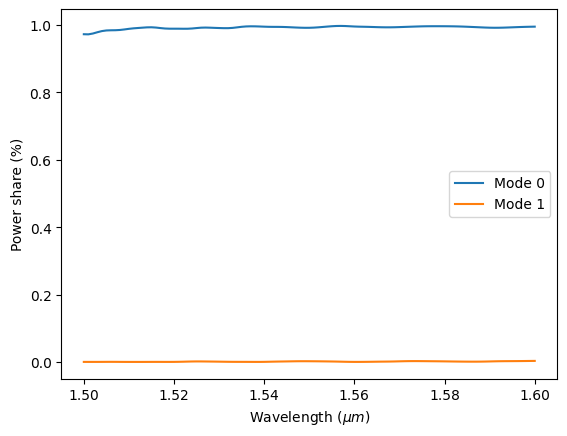

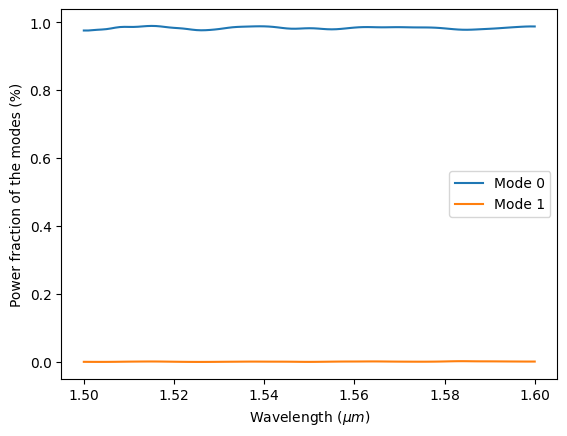

We can use the mode monitor to inspect the composition of each mode at the output. For the outer waveguide, we can see that the fundamental mode is dominant.

[10]:

mode_amp = sim_data["mode2"].amps.sel(direction="+")

mode_power = np.abs(mode_amp) ** 2 / T2

plt.plot(ldas, mode_power)

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Power share (%)")

plt.legend(["Mode 0", "Mode 1"])

plt.show()

Optimization#

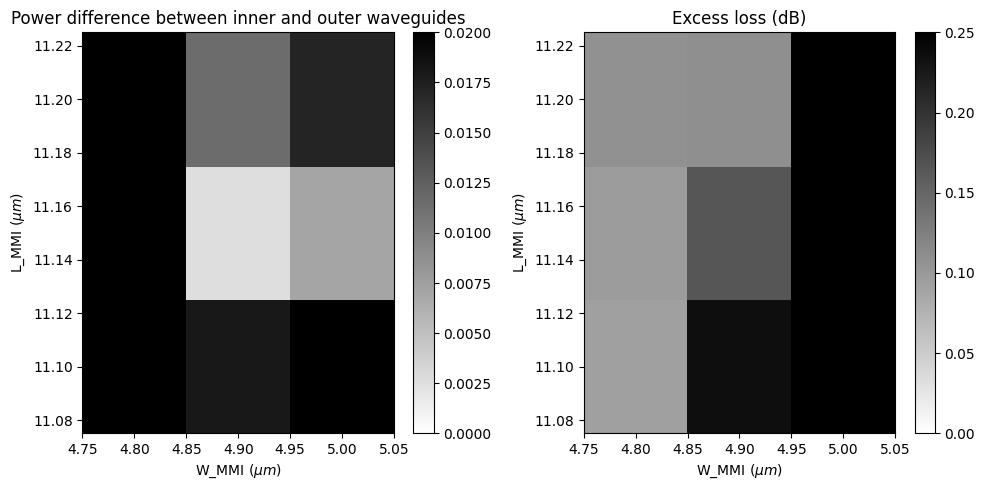

Further tuning of the geometric parameters is likely to improve the device’s performance further. We will perform a parameter sweep on two parameters to see if we can optimize the MMI. The goal is to achieve even power splitting among output waveguides while keeping the excess loss low.

The length of the MMI is swept from 11.1 to 11.2 \(\mu m\) in 50 nm step and the width from 4.8 to 5 \(\mu m\) in 100 nm step. This results in a total of 9 simulations. Since this is just a demonstration model, we limit the total number of simulations for the sake of time. In practice, one can perform much larger parameter sweeps to cover a larger parameter space.

[11]:

L_MMIs = np.linspace(11.1, 11.2, 3) # MMI length varies from 11.1 to 11.2 um

W_MMIs = np.linspace(4.8, 5, 3) # MMI width varies from 4.8 to 5 um

sims = {

f"L_MMI={L_MMI:.2f};W_MMI={W_MMI:.2f}": make_sim(L_MMI, W_MMI)

for L_MMI in L_MMIs

for W_MMI in W_MMIs

}

batch = web.Batch(simulations=sims, verbose=True)

batch_results = batch.run(path_dir="data")

[13:13:18] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- e146df9a-d0d1-4496-9739-2d23f8b414e9v1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 15f04405-2f42-4adb-a000-6ab329aaf5c6v1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 513f26a5-700e-4e0d-b98f-ca1697904f0cv1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 5046cd19-7d86-433d-9c85-19c1e900f9dcv1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 4ae1d2c0-9311-4dab-aa92-aec44474bffev1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 13908e29-319b-4a3c-944c-833f4200b341v1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- c8db1bec-419e-4f1c-a4df-89493329f6c2v1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 0534f858-4b17-49b6-80da-0735e1d5e59fv1'.

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 155f10f6-ed62-4cfc-b565-b64f0577f463v1'.

[13:13:24] Started working on Batch. container.py:475

[13:14:36] Maximum FlexCredit cost: 2.223 for the whole batch. container.py:479 Use 'Batch.real_cost()' to get the billed FlexCredit cost after the Batch has completed.

[13:16:32] Batch complete. container.py:522

Parse flux data into numpy arrays.

[12]:

T1 = np.zeros((len(L_MMIs), len(W_MMIs)))

T2 = np.zeros((len(L_MMIs), len(W_MMIs)))

for i, L_MMI in enumerate(L_MMIs):

for j, W_MMI in enumerate(W_MMIs):

sim_data = batch_results[f"L_MMI={L_MMI:.2f};W_MMI={W_MMI:.2f}"]

t1 = sim_data["flux1"].flux

T1[i, j] = t1[50] # the index 50 corresponds to the wavelength of 1550 nm

t2 = sim_data["flux2"].flux

T2[i, j] = t2[50]

Visualize power difference between outputs as well as the excess loss. The optimal design would have both values as close to 0 as possible. From the plots, we can see that in this parameter range, the smallest power different does not coincide with the lowest excess loss. If we prioritize small power difference, for example, L_MMI = 11.15 \(\mu m\) and W_MMI = 4.9 \(\mu m\) would be a good design choice.

[13]:

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 5))

plt.sca(ax1)

plt.pcolor(W_MMIs, L_MMIs, np.abs(T1 - T2), vmin=0, vmax=0.02, cmap="binary")

plt.colorbar()

plt.title("Power difference between inner and outer waveguides")

plt.xlabel("W_MMI ($\mu m$)")

plt.ylabel("L_MMI ($\mu m$)")

plt.sca(ax2)

plt.pcolor(

W_MMIs, L_MMIs, -10 * np.log10(2 * (T1 + T2)), vmin=0, vmax=0.25, cmap="binary"

)

plt.colorbar()

plt.title("Excess loss (dB)")

plt.xlabel("W_MMI ($\mu m$)")

plt.ylabel("L_MMI ($\mu m$)")

plt.show()

Plot field intensity for the optimal design.

[14]:

sim_data = batch_results["L_MMI=11.15;W_MMI=4.90"]

f, ax = plt.subplots(1, 1, figsize=(10, 10))

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", ax=ax, f=freq0

)

plt.show()

Plot transmission on each output waveguide as well as the total excess loss. For this design, at the central wavelength of 1.55 \(\mu m\), the power on each power is roughly equal. The total excess loss is below 0.2 dB.

[15]:

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 5))

T1 = sim_data["flux1"].flux

T2 = sim_data["flux2"].flux

plt.sca(ax1)

plt.plot(ldas, T1, ldas, T2)

plt.vlines(x=1.55, ymin=0.1, ymax=0.3, colors="black", ls="--")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Transmission to output")

plt.legend(("Inner output", "Outer outport"))

plt.sca(ax2)

excess_loss = -10 * np.log10(2 * (T1 + T2))

plt.plot(ldas, excess_loss)

plt.vlines(x=1.55, ymin=0, ymax=1, colors="black", ls="--")

plt.hlines(y=excess_loss[50], xmin=1.5, xmax=1.6, colors="black", ls="--")

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Excess loss (dB)")

plt.show()

In principle, the design can be further optimized by tuning other parameters such as gap size, tapper width, etc. if even lower excess loss is required. Finally, we can see the mode decomposition at the outer output waveguide. The fundamental mode is still dominant.

[16]:

mode_amp = sim_data["mode2"].amps.sel(direction="+")

mode_power = np.abs(mode_amp) ** 2 / T2

plt.plot(ldas, mode_power)

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Power fraction of the modes (%)")

plt.legend(["Mode 0", "Mode 1"])

plt.show()

[ ]: