Injecting modes in bent and angled waveguides

Contents

Injecting modes in bent and angled waveguides#

Here, we illustrate how we can use the ModeSource and ModeMonitor objects to study modes in bent and angled waveguides. This is very useful in simulations such as the waveguide to ring coupling.

For more simulation examples, please visit our examples page. If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials. FDTD simulations can diverge due to various reasons. If you run into any simulation divergence issues, please follow the steps outlined in our troubleshooting guide to resolve it.

[1]:

# standard python imports

import numpy as np

import matplotlib.pyplot as plt

import matplotlib as mpl

# tidy3D import

import tidy3d as td

from tidy3d import web

from tidy3d.plugins.mode import ModeSolver

Bent waveguide setup#

First, we will study mode injection and decomposition in a microring. We start by defining various simulation parameters, and the structures that enter the simulation. We simulate a silicon ring on a silicon oxide substrate, and the ring is defined using two Cylinders.

[2]:

# Unit length is micron.

wg_height = 0.22

wg_width = 0.9

# Radius of the simulated ring

radius = 2

# Waveguide and substrate materials

mat_wg = td.Medium(permittivity=3.48**2)

mat_sub = td.Medium(permittivity=1.45**2)

# Free-space wavelength (in um) and frequency (in Hz)

lambda0 = 1.55

freq0 = td.C_0 / lambda0

fwidth = freq0 / 10

# Simulation size inside the PML along propagation direction

sim_length = radius + 1.5

# Simulation domain size, resolution and total run time

sim_size = [sim_length, 2 * (radius + 1.5), 3]

run_time = 20 / fwidth

grid_spec = td.GridSpec.auto(min_steps_per_wvl=20, wavelength=lambda0)

# Substrate

substrate = td.Structure(

geometry=td.Box(

center=[0, 0, -sim_size[2]],

size=[td.inf, td.inf, 2 * sim_size[2] - wg_height],

),

medium=mat_sub,

)

# The ring is made by two cylinders

cyl1 = td.Structure(

geometry=td.Cylinder(

center=[0, 0, 0],

radius=radius - wg_width / 2,

length=wg_height,

axis=2,

),

medium=td.Medium(),

)

cyl2 = td.Structure(

geometry=td.Cylinder(

center=[0, 0, 0],

radius=radius + wg_width / 2,

length=wg_height,

axis=2,

),

medium=mat_wg,

)

Modal planes in bent waveguides#

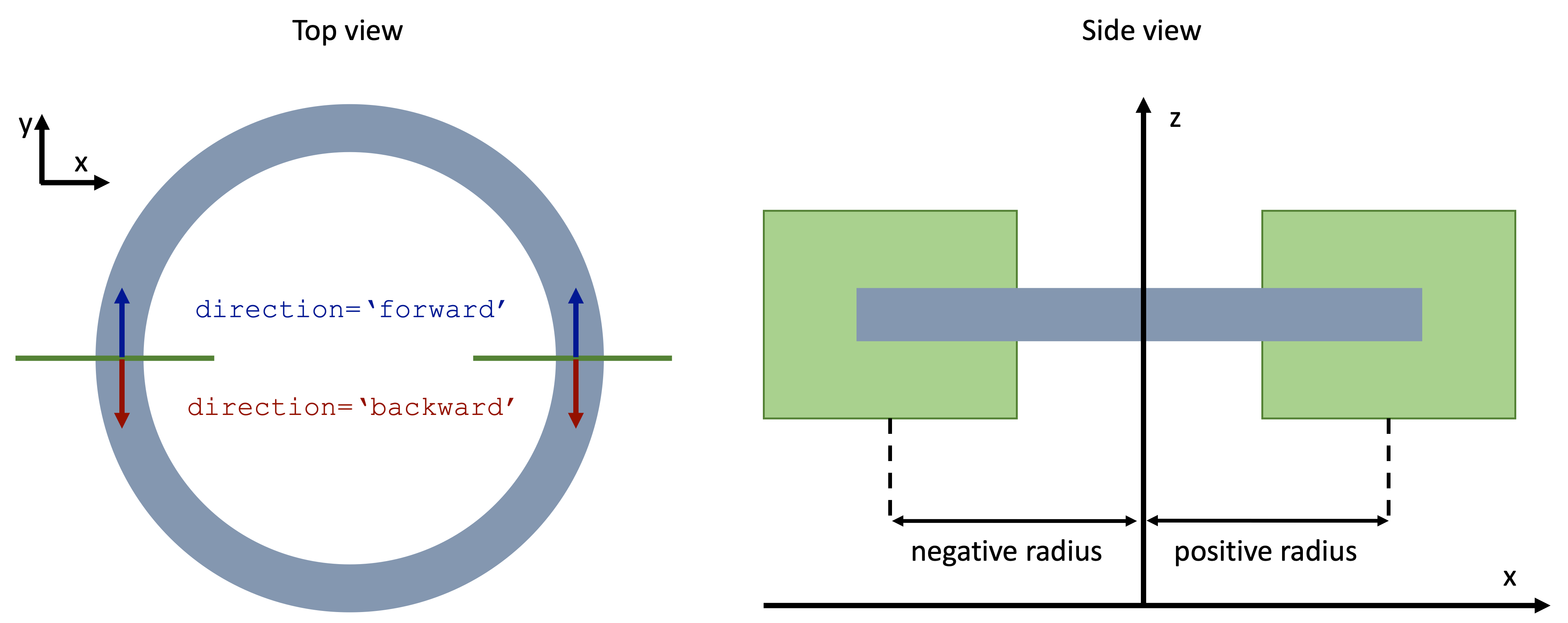

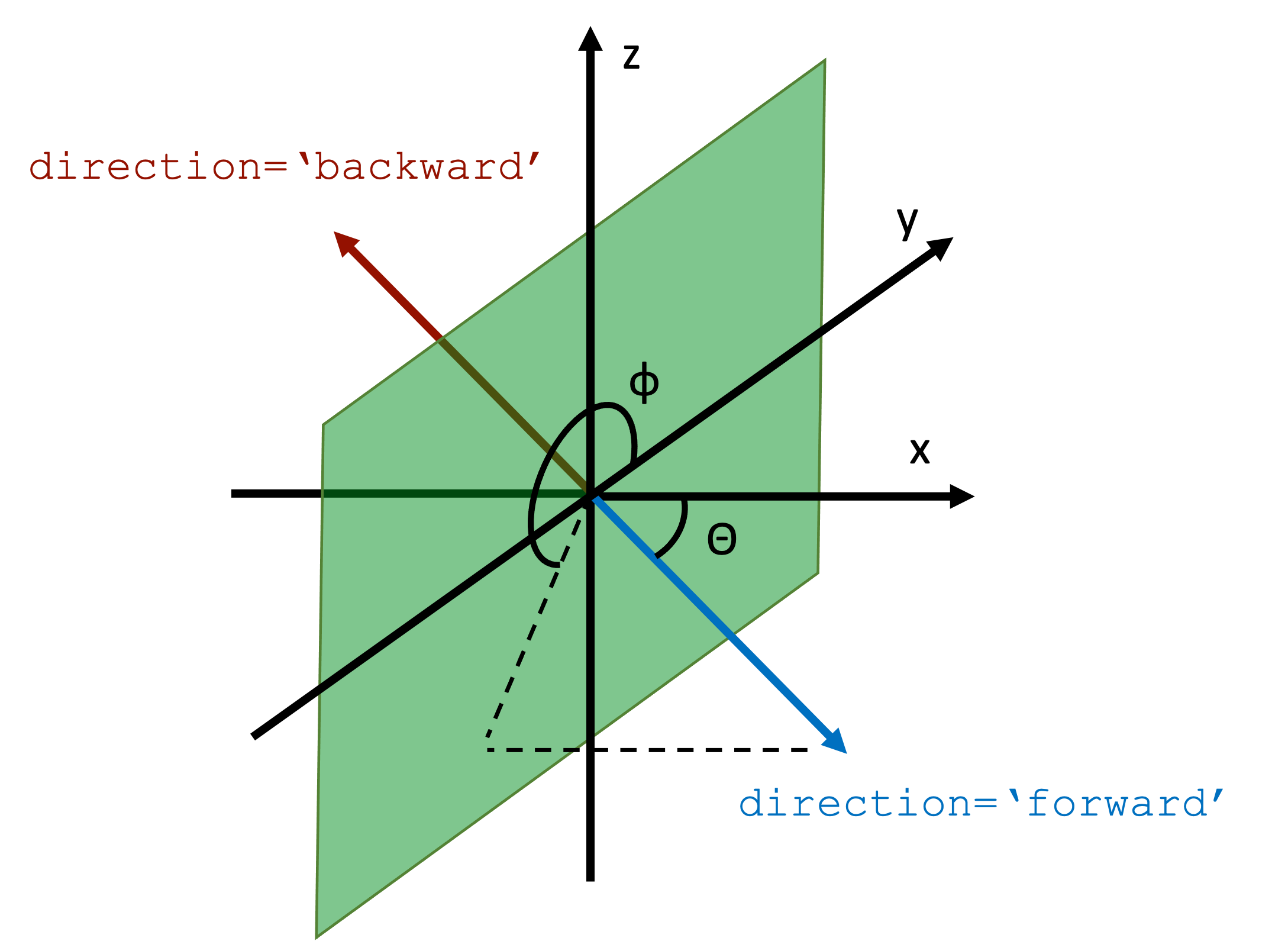

As usual, when initializing ModeSource and ModeMonitor objects, one of the three values of the size parameter must be zero. In this example, we also need to define the axis of the bend and the radius of the curvature. The definitions are schematically illustrated in the image below. The bend axis is the axis normal to the plane in which the bend lies, ('z' in the diagram below). In the mode specification, it is defined locally for the mode plane as one of the two axes

tangential to the plane. In the case of bends that lie in the xy-plane, the mode plane would be either in xz or in yz, so in both cases the correct setting is bend_axis=1, selecting the global z. The bend radius is counted from the center of the mode plane to the center of the curvature, along the tangential axis perpendicular to the bend axis. This radius can also be negative, if the center of the mode plane is smaller than the center of the bend, which is what we will

encounter in this example. Finally, we note that the 'forward' and 'backward' direction parameter can still be used to distinguish between the two propagation directions as in regular modal sources and monitors.

[3]:

# xy-plane frequency-domain field monitor; slightly offset in z for better structure viz below

field_mnt = td.FieldMonitor(

center=[0, 0, 0.05], size=[td.inf, td.inf, 0], freqs=[freq0], name="field"

)

# Flux monitor along the ring propagation direction

flux_mnt = td.FluxMonitor(

center=[0, radius, 0], size=[0, 3, 2], freqs=[freq0], name="flux"

)

[14:05:19] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

Running the simulation#

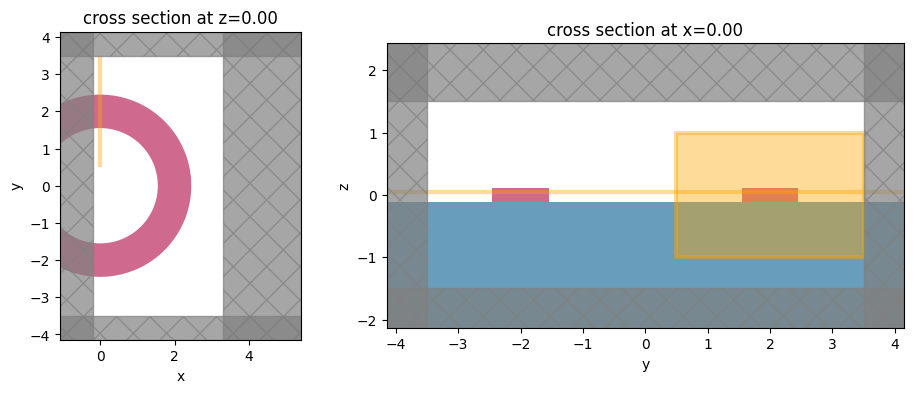

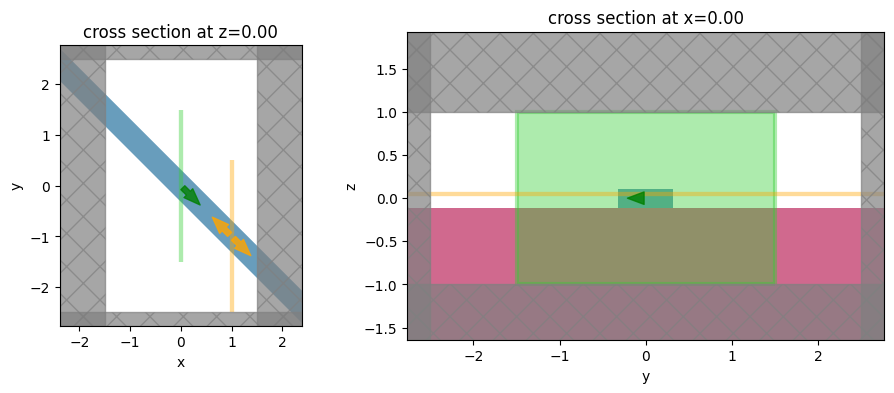

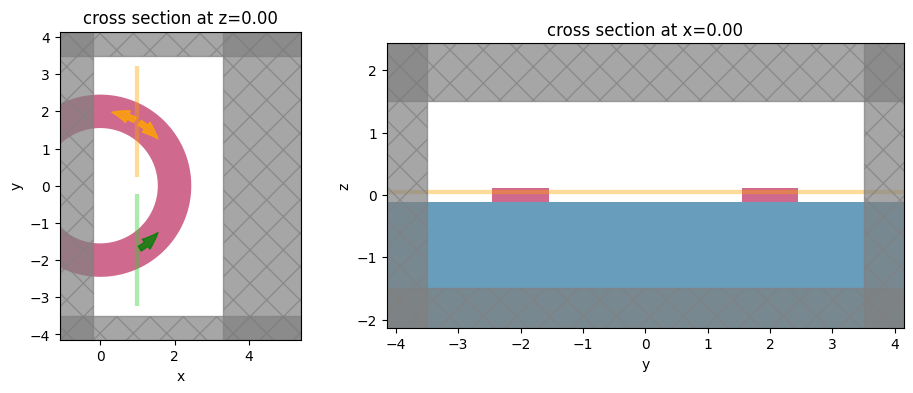

First, we visualize the simulation to make sure we have set up the device correctly. We will use 'absorber' boundaries along the x-direction, because these boundaries work better than PML for structures which are not translationally invariant along the boundary normal direction.

[4]:

# Simulation

sim = td.Simulation(

center=[sim_length / 2 - 0.2, 0, 0],

size=sim_size,

grid_spec=grid_spec,

structures=[substrate, cyl2, cyl1],

sources=[],

monitors=[field_mnt, flux_mnt],

run_time=run_time,

boundary_spec=td.BoundarySpec(

x=td.Boundary.absorber(), y=td.Boundary.pml(), z=td.Boundary.pml()

),

)

fig = plt.figure(figsize=(11, 4))

gs = mpl.gridspec.GridSpec(1, 2, figure=fig, width_ratios=[1, 2])

ax1 = fig.add_subplot(gs[0, 0])

ax2 = fig.add_subplot(gs[0, 1])

sim.plot(z=0, ax=ax1)

sim.plot(x=0, ax=ax2)

plt.show()

Note that Tidy3D is warning us that the simulation does not contain a source. However, since this simulation is used to construct the mode solver and will not be run directly, we can ignore this warning.

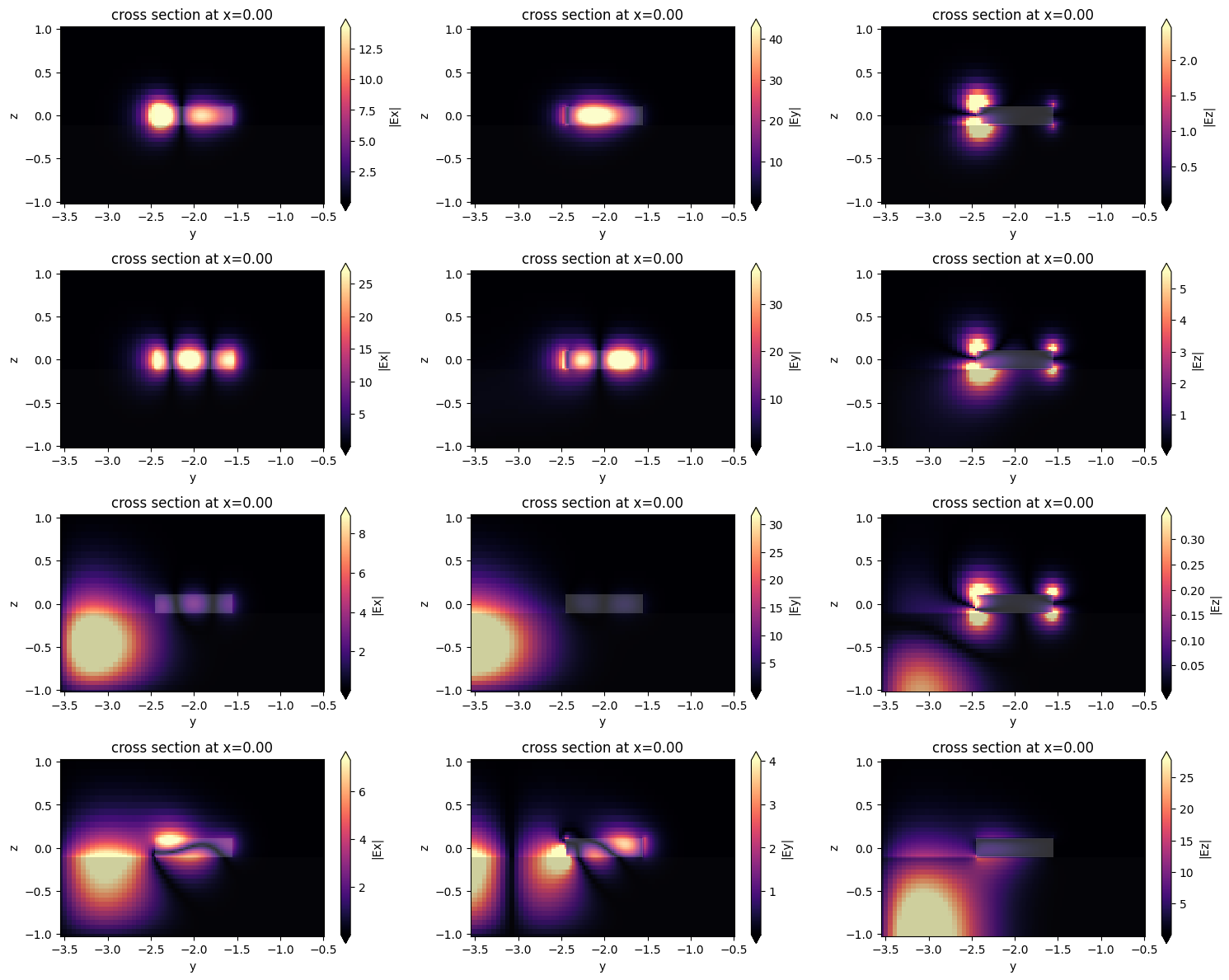

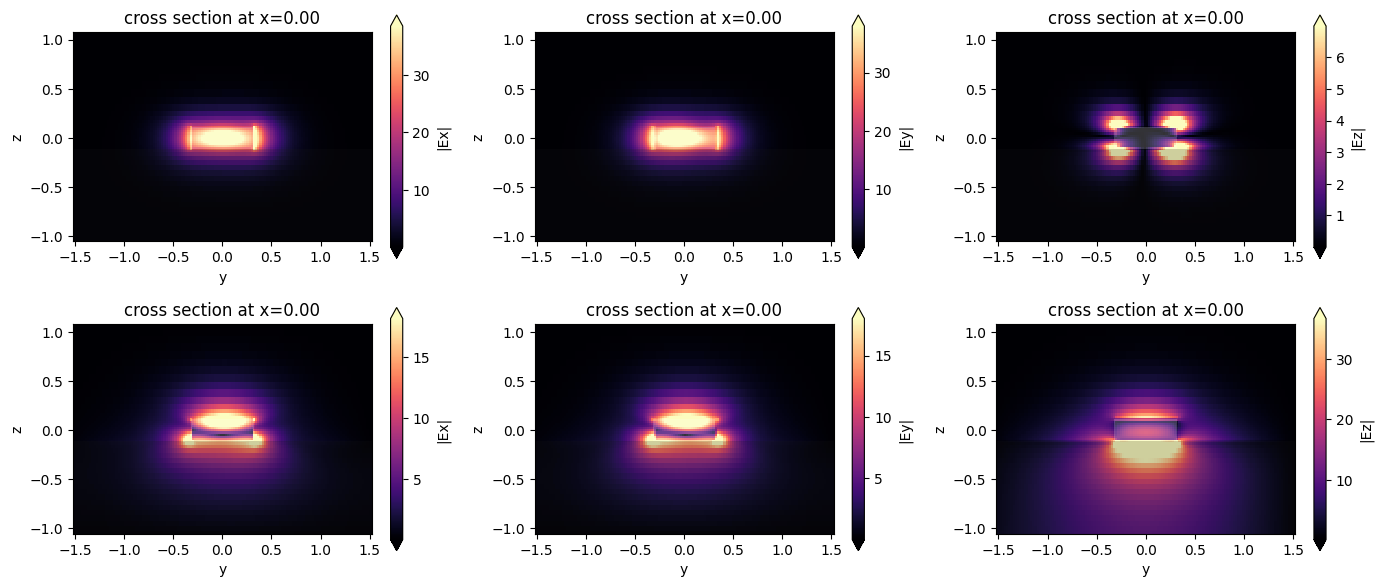

Next, we can compute the source modes to make sure that we inject the desired mode. When a bend radius \(R\) is used, the effective index \(n\) returned by the solver is such that the field evolves as \(e^{i n k_0 R \phi}\), with \(\phi\) the polar angle and \(k_0 = \omega/c\). This definition is such that in the limit of infinite \(R\), the effective index approaches that of a straight waveguide with the same cross-section. Based on our discussion and diagram above, we

set the bend_axis to 1, and the bend_radius at the position of the source is negative.

[5]:

# Modal source plane

source_plane = td.Box(center=[0, -radius, 0], size=[0, 3, 2])

num_modes = 4

# NB: negative radius since the plane position is at y=-radius

mode_spec = td.ModeSpec(num_modes=num_modes, bend_radius=-radius, bend_axis=1)

ms = ModeSolver(simulation=sim, plane=source_plane, freqs=[freq0], mode_spec=mode_spec)

modes = ms.solve()

f, axes = plt.subplots(num_modes, 3, tight_layout=True, figsize=(15, 12))

for axe, mode_index in zip(axes, range(num_modes)):

for ax, field_name in zip(axe, ("Ex", "Ey", "Ez")):

ms.plot_field(field_name, "abs", f=freq0, mode_index=mode_index, ax=ax)

plt.show()

WARNING: Use the remote mode solver with subpixel mode_solver.py:141 averaging for better accuracy through 'tidy3d.plugins.mode.web.run(...)'.

[14:05:20] WARNING: Mode field at frequency index 0, mode mode_solver.py:469 index 2 does not decay at the plane boundaries.

WARNING: Mode field at frequency index 0, mode mode_solver.py:469 index 3 does not decay at the plane boundaries.

Note that the last two of the computed modes are unphysical and for such modes that do not decay to zero at the plane boundary Tidy3D issues warnings. The fundamental mode looks like what we would expect, and we will use that mode for injection. Below, we also define a mode monitor, which is situated radially from the mode source, and so we use a positive value for the bend radius.

[6]:

# Mode source directly exported from the mode solver above

source_time = td.GaussianPulse(freq0=freq0, fwidth=fwidth)

mode_src = ms.to_source(source_time=source_time, mode_index=0, direction="+")

# Mode monitor after one-half round-trip around the ring; NB: positive radius

mode_mnt = td.ModeMonitor(

center=[0, radius, 0],

size=[0, 3, 2],

freqs=[freq0],

mode_spec=td.ModeSpec(num_modes=2, bend_radius=radius, bend_axis=1),

name="modes",

)

sim = sim.copy(update=dict(sources=[mode_src]))

sim = sim.copy(update=dict(monitors=[field_mnt, flux_mnt, mode_mnt]))

[7]:

sim_data = web.run(sim, task_name="ring_mode", path="data/sim_data.hdf5", verbose=True)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- e72836d9-ee47-4db7-8e28-be596cf13686v1'.

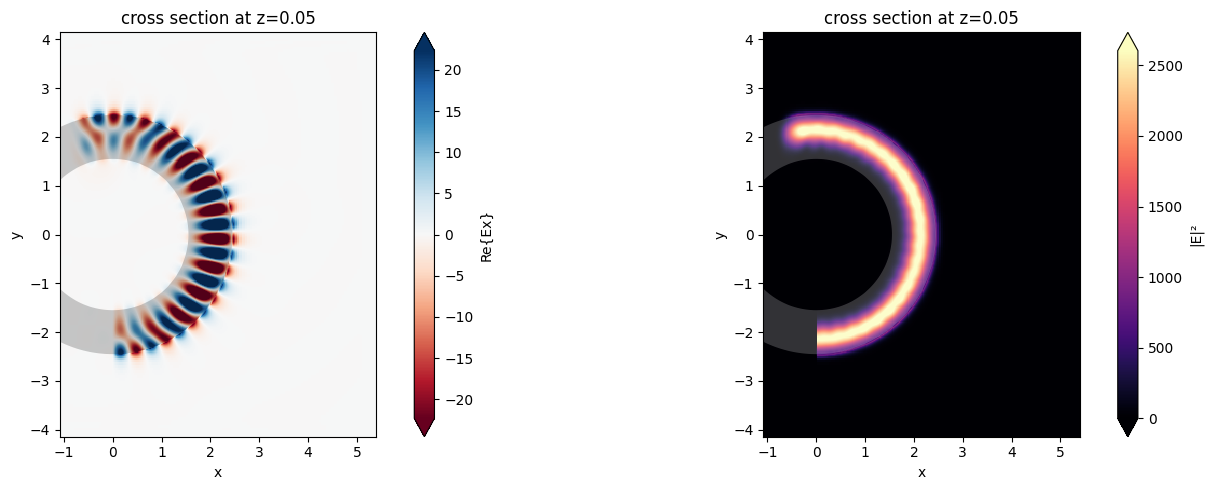

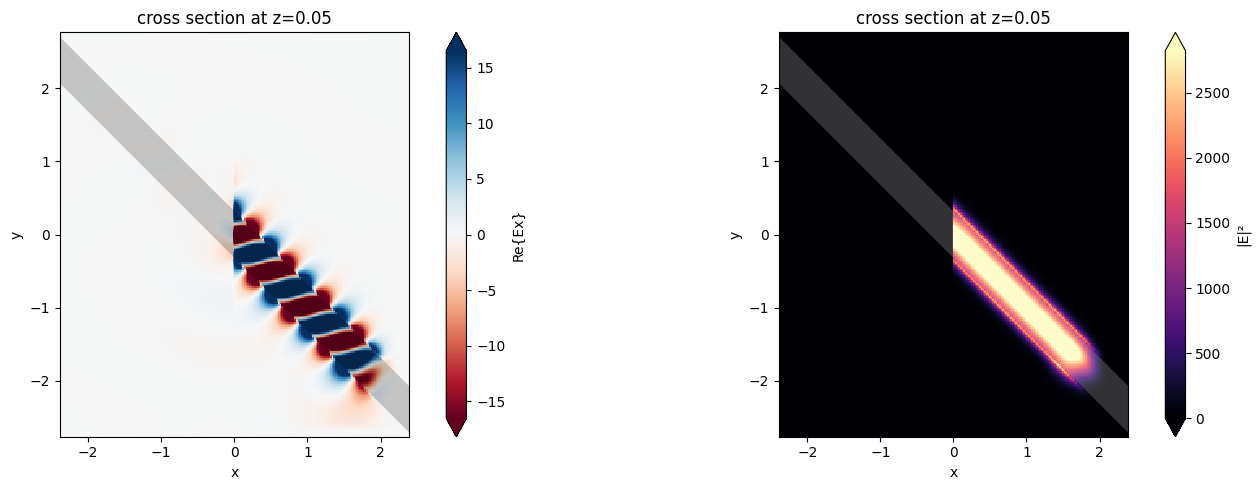

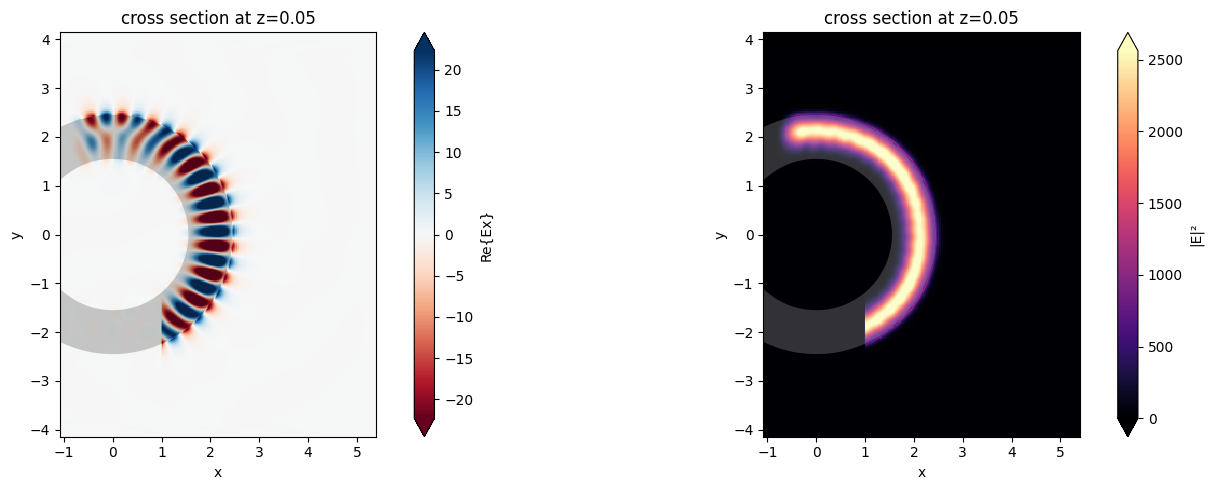

Finally, we visualize the results and verify that we get very close to unity transmission through the half-circle, and all the power is in the fundamental ring mode.

[8]:

print("Transmission flux: ", abs(sim_data["flux"].flux.data))

# note: 'backward' mode amplitude

mode_flux = abs(sim_data["modes"].amps.sel(direction="-")) ** 2

print("Flux in first two modes: ", np.array(mode_flux).ravel())

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(15, 5))

ax1 = sim_data.plot_field("field", "Ex", z=0.05, f=freq0, val="real", ax=ax1)

ax2 = sim_data.plot_field("field", "E", "abs^2", z=0.05, f=freq0, ax=ax2)

plt.show()

Transmission flux: [0.9981177]

Flux in first two modes: [0.99709518 0.00279819]

Angled waveguide setup#

Mode objects can also be set to inject and record propagation at a given angle with respect to the axis normal to the mode plane. The angle_theta and angle_phi parameters of ModeSource and ModeMonitor objects define the injection axis as illustrated in the figure below, with respect to the axis normal to the mode plane (x in the figure). Note that angle_theta must be smaller than \(\pi/2\). To inject in the backward direction, we can still use the direction

parameter as also shown in the figure. Similarly, the mode amplitudes computed in mode monitors are defined w.r.t. the forward and backward directions as illustrated.

[9]:

# Simulation size

sim_length = 3

sim_size = [sim_length, 5, 2]

# Define an angled waveguide as a PolySlab

wg_width = 0.45

theta = np.pi / 4

phi = np.pi

verts_x = np.array([-10, 10, 10, -10])

verts_y = verts_x * np.tan(theta)

verts_y[:2] -= wg_width / 2 / np.cos(theta)

verts_y[2:] += wg_width / 2 / np.cos(theta)

verts_y *= np.cos(phi) # this only works for phi = 0 or pi

verts = np.stack((verts_x, verts_y), axis=1)

waveguide = td.Structure(

geometry=td.PolySlab(vertices=verts, slab_bounds=(-wg_height / 2, wg_height / 2)),

medium=mat_wg,

)

# Modal source

src_pos = 0

mode_spec = td.ModeSpec(num_modes=2, angle_theta=theta, angle_phi=phi)

msource = td.ModeSource(

center=[src_pos, 0, 0],

size=[0, 3, 2],

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=mode_spec,

mode_index=0,

)

# Angled modal monitor

mnt_f = td.ModeMonitor(

center=[

sim_length / 2 - 0.5,

(sim_length / 2 - 0.5) * np.tan(theta) * np.cos(phi),

0,

],

size=[0, 3, 2],

freqs=[freq0],

mode_spec=mode_spec,

name="mnt_fwd",

)

We will once again use 'absorber' boundaries along x, since the angled waveguide is not translationally invariant in that direction.

[10]:

# Simulation

sim = td.Simulation(

size=sim_size,

grid_spec=grid_spec,

structures=[waveguide, substrate],

sources=[msource],

monitors=[field_mnt, mnt_f],

run_time=run_time,

boundary_spec=td.BoundarySpec(

x=td.Boundary.absorber(), y=td.Boundary.pml(), z=td.Boundary.pml()

),

)

fig = plt.figure(figsize=(11, 4))

gs = mpl.gridspec.GridSpec(1, 2, figure=fig, width_ratios=[1, 2.2])

ax1 = fig.add_subplot(gs[0, 0])

ax2 = fig.add_subplot(gs[0, 1])

sim.plot(z=0, ax=ax1)

sim.plot(x=0, ax=ax2)

plt.show()

Examine the modes. Note that Tidy3D is warning us about the second mode not decaying to zero at the plane boundary, which could mean that this mode is unphysical.

[11]:

ms = ModeSolver(

simulation=sim, plane=msource.geometry, mode_spec=mode_spec, freqs=[freq0]

)

modes = ms.solve()

f, axes = plt.subplots(mode_spec.num_modes, 3, tight_layout=True, figsize=(14, 6))

for axe, mode_index in zip(axes, range(mode_spec.num_modes)):

for ax, field_name in zip(axe, ("Ex", "Ey", "Ez")):

ms.plot_field(field_name, "abs", f=freq0, mode_index=mode_index, ax=ax)

plt.show()

Run the simulation and plot the results.

[12]:

sim_data = web.run(

sim, task_name="angled_waveguide", path="data/sim_data.hdf5", verbose=True

)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 375b467e-456f-4abf-878c-e0c7e7b3e802v1'.

[13]:

mode_flux = abs(sim_data["mnt_fwd"].amps.sel(direction="+")) ** 2

print("Flux in first two modes: ", np.array(mode_flux).ravel())

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(15, 5))

ax1 = sim_data.plot_field("field", "Ex", z=0.05, f=freq0, val="real", ax=ax1)

ax2 = sim_data.plot_field("field", "E", "abs^2", z=0.05, f=freq0, ax=ax2)

plt.show()

Flux in first two modes: [9.99327518e-01 6.24054752e-05]

Modes with both a bend and an angle#

We can also compose the two functionalities to inject and record modes in a bent waveguide in which the bend curvature is not in the same plane as the mode plane. This is illustrated below, using the same ring simulation but with a modification of the position of the ModeSource and ModeMonitor.

[14]:

# offset the source and monitor position by 'angle' along the ring

angle = np.pi / 6

# Simulation size for the ring simulation

sim_length = radius + 1.5

sim_size = [sim_length, 2 * (radius + 1.5), 3]

# Note: angle_phi = 0, bend_radius = -r

src_angled = td.ModeSource(

center=[radius * np.sin(angle), -radius * np.cos(angle), 0],

size=[0, 3, 2],

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

mode_spec=td.ModeSpec(

angle_theta=angle,

angle_phi=0,

bend_radius=-radius,

bend_axis=1,

),

)

# Note: angle_phi = np.pi, bend_radius = r

mnt_angled = td.ModeMonitor(

center=[radius * np.sin(angle), radius * np.cos(angle), 0],

size=[0, 3, 2],

freqs=[freq0],

mode_spec=td.ModeSpec(

num_modes=2,

angle_theta=angle,

angle_phi=np.pi,

bend_radius=radius,

bend_axis=1,

),

name="modes",

)

# Simulation

sim = td.Simulation(

center=[sim_length / 2 - 0.2, 0, 0],

size=sim_size,

grid_spec=grid_spec,

structures=[substrate, cyl2, cyl1],

sources=[src_angled],

monitors=[field_mnt, mnt_angled],

run_time=run_time,

boundary_spec=td.BoundarySpec(

x=td.Boundary.absorber(), y=td.Boundary.pml(), z=td.Boundary.pml()

),

subpixel=True,

)

fig = plt.figure(figsize=(11, 4))

gs = mpl.gridspec.GridSpec(1, 2, figure=fig, width_ratios=[1, 2])

ax1 = fig.add_subplot(gs[0, 0])

ax2 = fig.add_subplot(gs[0, 1])

sim.plot(z=0, ax=ax1)

sim.plot(x=0, ax=ax2)

plt.show()

[15]:

sim_data = web.run(

sim, task_name="angled_ring", path="data/sim_data.hdf5", verbose=True

)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 3872b199-3ce0-40ae-a23a-cdf96183641ev1'.

[16]:

mode_flux = abs(sim_data["modes"].amps.sel(direction="-")) ** 2

print("Flux in first two modes: ", np.array(mode_flux).ravel())

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(15, 5))

ax1 = sim_data.plot_field("field", "Ex", z=0.05, f=freq0, val="real", ax=ax1)

ax2 = sim_data.plot_field("field", "E", "abs^2", z=0.05, f=freq0, ax=ax2)

plt.show()

Flux in first two modes: [0.99269782 0.00857491]

For more integrated photonic examples such as the 8-Channel mode and polarization de-multiplexer, the broadband bi-level taper polarization rotator-splitter, and the broadband directional coupler, please visit our examples page.

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials.

[ ]: