Waveguide bragg gratings

Contents

Waveguide bragg gratings#

Bragg gratings are often used in waveguides, such as optical fibres, which can reflect light of certain frequencies while transmitting others. This is typically achieved by periodically changing the refractive index or dielectric constant in a section of the waveguide, and the reflective and transmitting frequency bands are controlled by appropriately designing the periodicity and material or geometry parameters of the grating.

In this example, sections of two Bragg gratings will be simulated. The first one involves a waveguide with a perfectly aligned corrugation on either side, which causes it to act as a reflector. The second one is similar, but with the corrugation on one side misaligned with the corrugation on the other side, so that the structure primarily transmits power.

Reference: Xu Wang, Yun Wang, Jonas Flueckiger, Richard Bojko, Amy Liu, Adam Reid, James Pond, Nicolas A. F. Jaeger, and Lukas Chrostowski, "Precise control of the coupling coefficient through destructive interference in silicon waveguide Bragg gratings," Opt. Lett. 39, 5519-5522 (2014), DOI: 10.1364/OL.39.005519

As a relevant example, please see the distributed Bragg reflector. For more integrated photonic examples such as the 8-Channel mode and polarization de-multiplexer, the broadband bi-level taper polarization rotator-splitter, and the broadband directional coupler, please visit our examples page.

If you are new to the finite-difference time-domain (FDTD) method, we highly recommend going through our FDTD101 tutorials.

[1]:

# basic imports

import numpy as np

import matplotlib.pylab as plt

# Tidy3D imports

import tidy3d as td

Structure Setup#

First, the geometry of the structure is defined. Both waveguides are set up in the same simulation side-by-side.

[2]:

# materials

Air = td.Medium(permittivity=1.0)

Si = td.Medium(permittivity=3.47**2)

SiO2 = td.Medium(permittivity=1.44**2)

# geometric parameters

wg_height = 0.22

wg_feed_length = 0.75

wg_feed_width = 0.5

corrug_width = 0.05

num_periods = 50

period = 0.324

shift = period / 2

corrug_length = period / 2

wg_length = num_periods * period

wg_width = wg_feed_width - corrug_width

wavelength0 = 1.532

freq0 = td.C_0 / wavelength0

fwidth = freq0 / 40.0

run_time = 4.0e-12

wavelength_min = td.C_0 / (freq0 + fwidth)

# place the two waveguides with their centres half a free-space wavelength apart

wg1_y = wavelength0 / 2

wg2_y = -wavelength0 / 2

# small buffer added to structures so they extend into the PML a bit

pml_buffer = period

# waveguide 1

wg1_size = [wg_length + pml_buffer, wg_width, wg_height]

wg1_center = [0, wg1_y, wg_height / 2]

wg1_medium = Si

# waveguide 2

wg2_size = [wg_length + pml_buffer, wg_width, wg_height]

wg2_center = [0, wg2_y, wg_height / 2]

wg2_medium = Si

# corrugation setup for waveguide 1

cg1_size = [corrug_length, corrug_width, wg_height]

cg1_center_plus = [

-wg_length / 2 + corrug_length / 2,

wg_width / 2 + corrug_width / 2 + wg1_y,

wg_height / 2,

]

cg1_center_minus = [

-wg_length / 2 + corrug_length / 2,

-wg_width / 2 - corrug_width / 2 + wg1_y,

wg_height / 2,

]

cg1_medium = Si

# corrugation setup for waveguide 2

cg2_size = [corrug_length, corrug_width, wg_height]

cg2_center_plus = [

-wg_length / 2 + corrug_length / 2,

wg_width / 2 + corrug_width / 2 + wg2_y,

wg_height / 2,

]

cg2_center_minus = [

-wg_length / 2 + corrug_length / 2 + shift,

-wg_width / 2 - corrug_width / 2 + wg2_y,

wg_height / 2,

]

cg2_medium = Si

# substrate

sub_size = [td.inf, td.inf, 2]

sub_center = [0, 0, -1.0]

sub_medium = SiO2

# create the substrate

substrate = td.Structure(

geometry=td.Box(center=sub_center, size=sub_size),

medium=sub_medium,

name="substrate",

)

# create the first waveguide

waveguide_1 = td.Structure(

geometry=td.Box(center=wg1_center, size=wg1_size),

medium=wg1_medium,

name="waveguide_1",

)

# create the second waveguide

waveguide_2 = td.Structure(

geometry=td.Box(center=wg2_center, size=wg2_size),

medium=wg2_medium,

name="waveguide_2",

)

# create the corrugation for the first waveguide

corrug1_plus = []

corrug1_minus = []

for i in range(num_periods):

# corrugation on the +y side

center = cg1_center_plus

if i > 0:

center[0] += period

plus = td.Structure(

geometry=td.Box(center=center, size=cg1_size),

medium=cg1_medium,

name=f"corrug1_plus_{i}",

)

# corrugation on the -y side

center = cg1_center_minus

if i > 0:

center[0] += period

minus = td.Structure(

geometry=td.Box(center=center, size=cg1_size),

medium=cg1_medium,

name=f"corrug1_minus_{i}",

)

corrug1_plus.append(plus)

corrug1_minus.append(minus)

# create the corrugation for the second waveguide

corrug2_plus = []

corrug2_minus = []

for i in range(num_periods):

# corrugation on the +y side

center = cg2_center_plus

if i > 0:

center[0] += period

plus = td.Structure(

geometry=td.Box(center=center, size=cg2_size),

medium=cg2_medium,

name=f"corrug2_plus_{i}",

)

# corrugation on the -y side

center = cg2_center_minus

if i > 0:

center[0] += period

minus = td.Structure(

geometry=td.Box(center=center, size=cg2_size),

medium=cg2_medium,

name=f"corrug2_minus_{i}",

)

corrug2_plus.append(plus)

corrug2_minus.append(minus)

# full simulation domain

sim_size = [

wg_length + wavelength0 * 1.5,

2 * wavelength0 + wg_width + 2 * corrug_width,

3.7,

]

sim_center = [0, 0, 0.0]

# boundary conditions - Bloch boundaries are used to emulate an infinitely long grating

boundary_spec = td.BoundarySpec(

# x=td.Boundary.bloch(bloch_vec=num_periods/2),

x=td.Boundary.pml(),

y=td.Boundary.pml(),

z=td.Boundary.pml(),

)

# grid specification

grid_spec = td.GridSpec.auto(min_steps_per_wvl=20)

Source Setup#

A mode source is defined for each waveguide.

[3]:

# mode source for waveguide 1

source1_time = td.GaussianPulse(freq0=freq0, fwidth=fwidth, amplitude=1)

mode_src1 = td.ModeSource(

center=[-wg_length / 2 + period, wg1_y, wg_height / 2],

size=[0, waveguide_1.geometry.size[1] * 2, waveguide_1.geometry.size[2] * 2],

mode_index=0,

direction="+",

source_time=source1_time,

mode_spec=td.ModeSpec(),

)

# mode source for waveguide 2

source2_time = td.GaussianPulse(freq0=freq0, fwidth=fwidth, amplitude=1)

mode_src2 = td.ModeSource(

center=[-wg_length / 2 + period, wg2_y, wg_height / 2],

size=[0, waveguide_2.geometry.size[1] * 2, waveguide_2.geometry.size[2] * 2],

mode_index=0,

direction="+",

source_time=source2_time,

mode_spec=td.ModeSpec(),

)

Monitor Setup#

To visualize the field distribution in the waveguides, a monitor is placed in the xy plane cutting through both waveguides. A pair of flux monitors is also placed on the far side the demonstrate the transmission and reflection characteristics.

[4]:

# create monitors

monitor_xy = td.FieldMonitor(

center=[0, 0, wg_height / 2],

size=[wg_length, 2 * wavelength0 + wg_width + 2 * corrug_width, 0],

freqs=[freq0],

name="fields_xy",

)

freqs = np.linspace(freq0 - 2 * fwidth, freq0 + 2 * fwidth, 200)

monitor_flux_aligned = td.FluxMonitor(

center=[wg_length / 2 - period, wg1_y, wg_height / 2],

size=[0, waveguide_1.geometry.size[1] * 2, waveguide_1.geometry.size[2] * 2],

freqs=freqs,

name="flux_aligned",

)

monitor_flux_misaligned = td.FluxMonitor(

center=[wg_length / 2 - period, wg2_y, wg_height / 2],

size=[0, waveguide_2.geometry.size[1] * 2, waveguide_2.geometry.size[2] * 2],

freqs=freqs,

name="flux_misaligned",

)

[10:20:41] WARNING: Default value for the field monitor monitor.py:261 'colocate' setting has changed to 'True' in Tidy3D 2.4.0. All field components will be colocated to the grid boundaries. Set to 'False' to get the raw fields on the Yee grid instead.

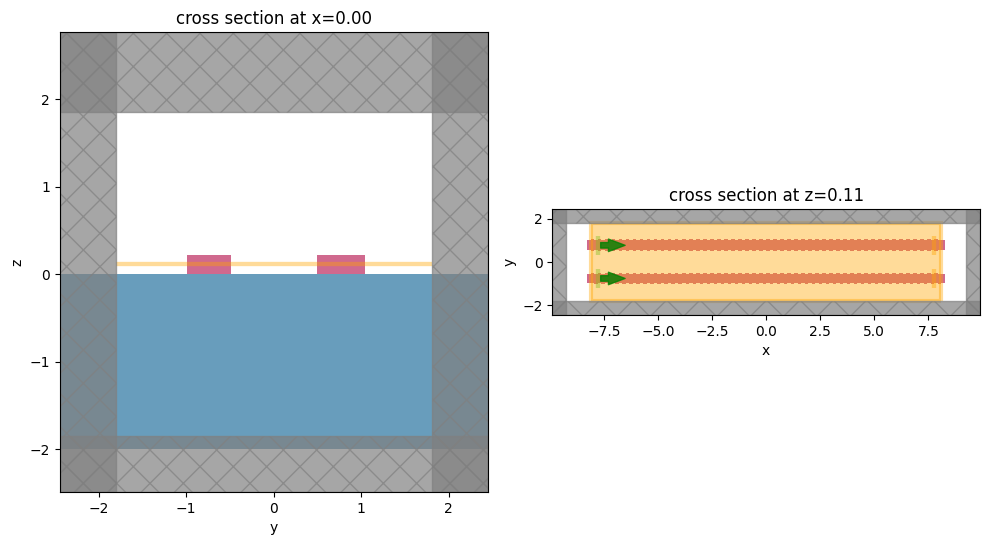

Create Simulation#

All the structures, sources, and monitors are consolidated, and the simulation is created and visualized.

[5]:

# list of all structures

structures = (

[substrate, waveguide_1, waveguide_2]

+ corrug1_plus

+ corrug1_minus

+ corrug2_plus

+ corrug2_minus

)

# list of all sources

sources = [mode_src1, mode_src2]

# list of all monitors

monitors = [monitor_xy, monitor_flux_aligned, monitor_flux_misaligned]

# create the simulation

sim = td.Simulation(

center=sim_center,

size=sim_size,

grid_spec=grid_spec,

structures=structures,

sources=sources,

monitors=monitors,

run_time=run_time,

boundary_spec=boundary_spec,

)

# plot the simulation domain

f, (ax1, ax3) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 6))

sim.plot(x=0, ax=ax1)

sim.plot(z=wg_height / 2, ax=ax3)

plt.show()

Run Simulation#

[6]:

# run simulation

import tidy3d.web as web

sim_data = web.run(sim, task_name="bragg", path="data/bragg.hdf5", verbose=True)

View task using web UI at webapi.py:190 'https://tidy3d.simulation.cloud/workbench?taskId=fdve- 7dd8e133-a7b2-487f-a92a-515cd54d110av1'.

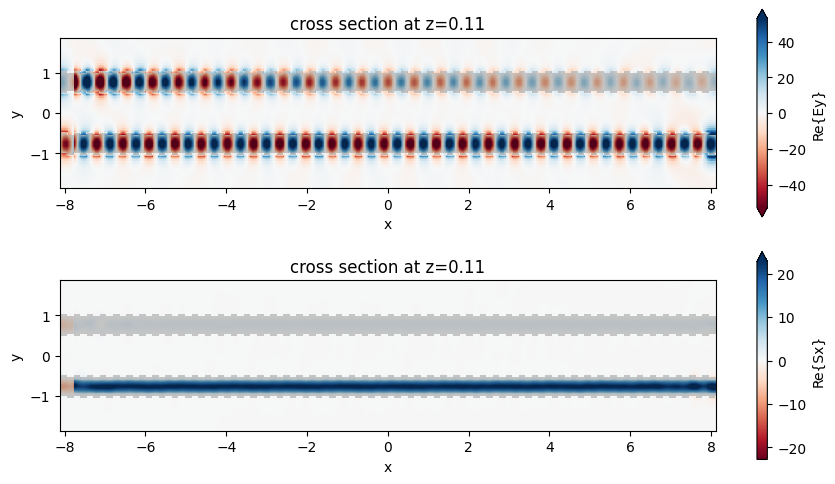

Field Plot#

The frequency-domain fields are plotted in the xy plane cutting through the waveguides. We notice that the grating with aligned corrugation effectively reflects power at the design frequency, while the misalignment in the second grating causes it to be mostly transmissive.

[7]:

# plot fields on the monitor

fig, ax = plt.subplots(2, 1, tight_layout=True, figsize=(9, 5))

sim_data.plot_field(

field_monitor_name="fields_xy", field_name="Ey", val="real", f=freq0, ax=ax[0]

)

sim_data.plot_field(

field_monitor_name="fields_xy", field_name="Sx", val="real", f=freq0, ax=ax[1]

)

plt.show()

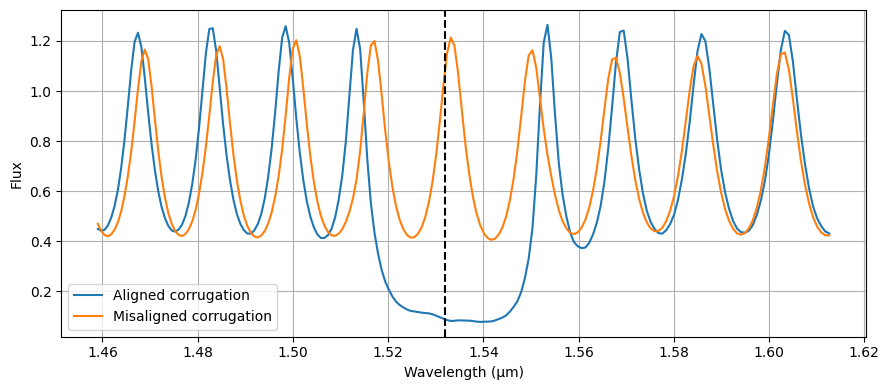

Transmission and Reflection#

The observations made in the field plot above can be confirmed by plotting the flux recorded by the flux monitors as a function of frequency. In the region of the design frequency, indicated by the dashed black line, the drop in flux for the aligned-corrugation grating confirms its reflective property.

[8]:

fig, ax = plt.subplots(figsize=(9, 4), tight_layout=True)

# plot transmitted flux for each waveguide

ax.plot(td.C_0 / freqs, sim_data["flux_aligned"].flux, label="Aligned corrugation")

ax.plot(

td.C_0 / freqs, sim_data["flux_misaligned"].flux, label="Misaligned corrugation"

)

# vertical line at design frequency

ax.axvline(td.C_0 / freq0, ls="--", color="k")

ax.set(xlabel="Wavelength (µm)", ylabel="Flux")

ax.grid(True)

plt.legend()

plt.show()