Postprocessing#

Nondimensional Outputs#

The following list shows some commonly used nondimensional variables in the output files:

Property |

Ref. value for nondim. |

Examples in Flow360 |

|---|---|---|

Length |

{volumeOutput, surfaceOutput}->wallDistance |

|

Density |

{surfaceOutput, volumeOutput}->primitiveVars |

|

Velocity |

{surfaceOutput, volumeOutput}->primitiveVars |

|

Pressure |

{surfaceOutput, volumeOutput}->primitiveVars, surfaceOutput->nodeForcesPerUnitArea |

|

Temperature |

volumeOutput->T |

|

Heat Flux |

surfaceOutput->heatFlux |

|

Force |

force in BET output |

|

Moment |

moment in BET output |

Besides the above nondimensional quantities, there are also many coefficients commonly used in the community of computational fluid dynamics,

e.g. pressure coefficient (

Caution

It should be noted that the reference velocity freestream->Mach or freestream->MachRef by users.

Its definition can be found in the case configuration page.

It is not the same as the reference velocity (

The force coefficients and moment coefficients exported by Flow360 are listed in Table 54.

These coefficients are shown in “Forces” tab of each case in Flow360 web portal.

These coefficients can also be fetched by the flow360client.case.GetCaseTotalForces(caseId) python API call.

Property |

Definition |

|---|---|

CL |

|

CD |

|

CFx |

|

CFy |

|

CFz |

|

CMx |

|

CMy |

|

CMz |

Note

In the above table, all quantities in “Definition” column are dimensional.

The entries

History Files#

At the completion of a case the Flow360 solver will generate up to 9 LOG and CSV files containing run information and the history of important variables. These LOG and CSV files can be downloaded from the WebUI or via the following python API calls:

To download the LOG files, where caseId is the alphanumeric case identifier:

flow360client.case.DownloadSolverOut('caseId', fileName='flow360_case.user.log')

To download the history CSV files please use this python API command.

Note

If your case does not contain a BET or AD model, then “bet_forces.csv” and “actuatorDisk_output.csv” will not be available.

Except for the data contained within “bet_forces.csv” and “actuatorDisk_output.csv”, all the downloadable data mentioned above can be visualized on the WebUI under the Convergence, MinMax and Forces tabs as outlined below.

Fig. 274 Tabs to visualize key case history variables.#

Actuator Disk Output#

The Actuator Disk (AD) output file, “actuatorDisk_output.csv”, has the following headers: physical_step, pseudo_step, Disk0_Power, Disk0_Force, Disk0_Moment, Disk1_Power, Disk1_Force, Disk1_Moment ....DiskN_Power, DiskN_Force, DiskN_Moment for the N disks.

The power columns contains the Cp power coefficient:

The Force and Moment columns simply report the constant integrated total force and moment as entered by the user.

BET Loading Output#

The Blade Element Theory (BET) output file, “bet_forces.csv”, contains the time history of the following quantities:

Integrated x-, y-, z-component of nondimensional forces and nondimensional moments acted on each disk, represented by “Disk[diskID]_Force_x,_y,_z” and “Disk[diskID]_Moment_x,_y,_z”, respectively. The nondimensional force is defined as,

(60)#and nondimensional moment as,

(61)#where the moment center is the

centerOfRotationof each disk, defined in BETDisks of Flow360.json.Note

The above Force and Moment values are forces and moments acting on the solid. Forces and moments acting on the fluid are the inverse of the above.

Attention

The x-, y-, z-component of Disk[diskID]_Force and Disk[diskID]_Moment is reported in the global inertial reference frame. This reference frame is defined in the mesh file.

Sectional thrust coefficient

nLoadingNodes.Note

The definition of

and

where

Important

All the quantities in the right hand side of Eq.(60), Eq.(61), Eq.(62) and Eq.(63) are dimensional, which are different from the nondimensional values in BETDisks (list) of Flow360.json. For example, at the first disk’s first blade’s first radial location

Warning

For steady-state simulations with BET models, the resulting

Here is an example of the header of a “bet_forces.csv” file from a simulation containing two BET disks (assume nLoadingNodes = 20, numberOfBlades = 3 for each disk):

physical_step, pseudo_step,

Disk0_Force_x, Disk0_Force_y, Disk0_Force_z, Disk0_Moment_x, Disk0_Moment_y, Disk0_Moment_z,

Disk0_Blade0_R0_Radius, Disk0_Blade0_R0_ThrustCoeff, Disk0_Blade0_R0_TorqueCoeff,

Disk0_Blade0_R1_Radius, Disk0_Blade0_R1_ThrustCoeff, Disk0_Blade0_R1_TorqueCoeff,

...

Disk0_Blade0_R19_Radius, Disk0_Blade0_R19_ThrustCoeff, Disk0_Blade0_R19_TorqueCoeff,

Disk0_Blade1_R0_Radius, Disk0_Blade1_R0_ThrustCoeff, Disk0_Blade1_R0_TorqueCoeff,

Disk0_Blade1_R1_Radius, Disk0_Blade1_R1_ThrustCoeff, Disk0_Blade1_R1_TorqueCoeff,

...

Disk0_Blade1_R19_Radius, Disk0_Blade1_R19_ThrustCoeff, Disk0_Blade1_R19_TorqueCoeff,

Disk0_Blade2_R0_Radius, Disk0_Blade2_R0_ThrustCoeff, Disk0_Blade2_R0_TorqueCoeff,

Disk0_Blade2_R1_Radius, Disk0_Blade2_R1_ThrustCoeff, Disk0_Blade2_R1_TorqueCoeff,

...

Disk0_Blade2_R19_Radius, Disk0_Blade2_R19_ThrustCoeff, Disk0_Blade2_R19_TorqueCoeff,

Disk1_Force_x, Disk1_Force_y, Disk1_Force_z, Disk1_Moment_x, Disk1_Moment_y, Disk1_Moment_z,

...

...

...

Disk1_Blade2_R19_Radius, Disk1_Blade2_R19_ThrustCoeff, Disk1_Blade2_R19_TorqueCoeff

Aeroacoustic Output#

The aeroacoustic output file has the name “total_acoustics_v3.csv” which contains the overall aeroacoustic results for all wall patches combined. If writePerSurfaceOutput has been set to true in aeroacousticOutput then “surface_NameOfPatch_acoustics_v3.csv” will also be available for each of the individual wall patches.

Each CSV file contains the following headers: “time, physical_step, observer_0_pressure, observer_1_pressure, … , observer_N_pressure, observer_0_thickness, … , observer_N_thickness, observer_0_loading, … , observer_N_loading”, where N+1 is the total number of observers specified in the aeroacousticOutput section of the case JSON file. The "_pressure" columns provide the acoustic pressure signal at the observer locations and the "_thickness" and "_loading" columns correspond to the thickness and loading noise contributions to the acoustic pressure signal.

The output file contains the non-dimensional acoustic pressure signal as a function of time, where time is the non-dimensional time specified in the first column. The second column is the physical step of the simulation at which the time is observed, assuming constant time step size.

Note

The time of observation is not necessarily contained in the simulation time as it will take a finite amount of time for the acoustic signal to propagate from the solid surfaces to the observers’ locations. As each observer can have a different distance from the solid surface, certain observers will have a proper acoustic signal before other observers at any given time. Consequently, the acoustic signal at each observer is padded with zeros at the beginning and the end of the time history, depending on the validity of the acoustic signal.

Heat Transfer#

The file “surface_heat_transfer_v2.csv” contains surface integrals of the heat flux computed from nondimensional quantities. To find the dimensional heat transfer rate, multiply the nondimensional value by

Visualization Files#

Supported visualization output formats are:

ParaView (.pvtu)

Tecplot (.szplt)

The export file type as well as the variables exported are selected in the Flow360.json case input file as per these conventions.

Data exports are nondimensional. Example dimensional conversions are shown below:

Velocity#

Because the reference value of velocity is velocityX with the freestream speed of sound.

Assuming the freestream speed of sound is 340 m/s and velocityX is 0.6 in the ParaView/Tecplot file, then the dimensional velocity in x-direction is

Pressure#

The reference value of pressure is p is 0.65 in the ParaView/Tecplot file, then the dimensional pressure is

Node Force Per Unit Area#

nodeForcesPerUnitArea is the total (pressure + friction) force applied at a node divided by the surface area attributed to the given node. It is particularly useful to calculate sectional loading values. If integrated over the whole surface, nodeForcesPerUnitArea would equal the total forces acting on the surface. The reference value to dimensionalize nodeForcesPerUnitArea is the same as for pressure

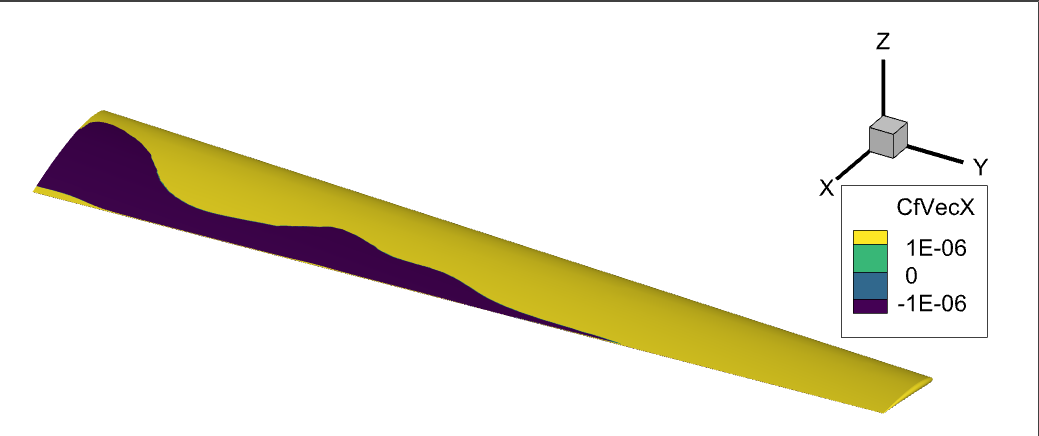

Skin Friction Coefficient#

As defined, CfVec is the skin friction coefficient vector and Cf is the magnitude of that vector. To calculate the viscous stress on the wall:

The CfVec vector is very useful to locate regions of boundary layer separation. Fully attached flow follows the surface along the streamwise direction, whereas separated flow induces local recirculation.

A strategy to investigate separation is to visualize skin friction in the streamwise direction. For example, consider flow in the x-direction over a wing, regions of negative CfVecX indicate boundary layer separation.

If we set a visualization scale with 3 levels, say -1e-6, 0 and 1e-6 we will have all the negative values be one color and all the positive values be another, hence we can easily find the regions of separated flows on the surface. See the image below:

Fig. 275 The x-component of skin friction coefficient showing the attached (yellow) and separated (dark purple) flow regions on this wing at a high angle of attack.#

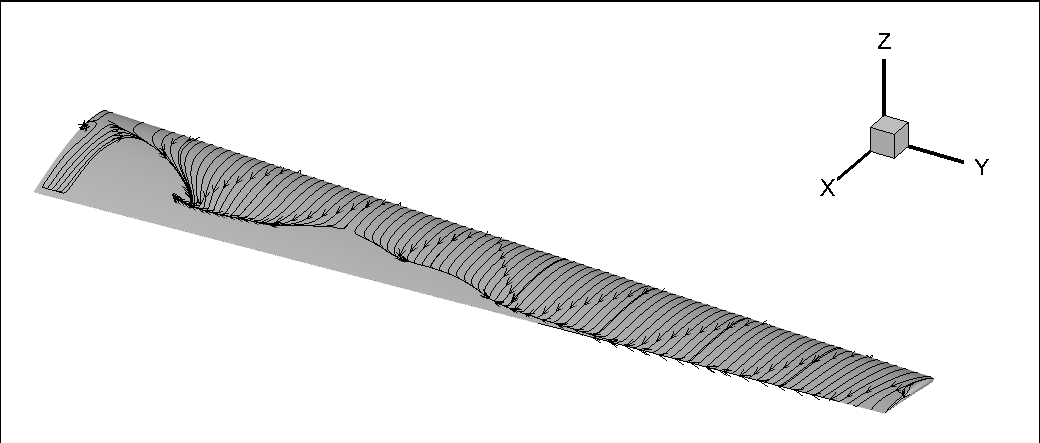

The separated flow regions on the surface can also be visualized by using surface streamlines. Because the velocities on the surface are, by definition of a NoSlipWall, equal to 0, the key is to change the surface streamline integration parameters from velocity{X,Y,Z} to CfVec{X,Y,Z}.

Fig. 276 Surface streamlines showing recirculation regions.#

Pressure Coefficient#

To calculate the dimensional pressure simply use:

where

Total Pressure Coefficient#

By definition total pressure is the sum of static pressure

As shown in equations 26 and 29 in the appendix of this paper, the total pressure coefficient

where the heat capacity ratio

Just like we used CfVecX to visualize the surface separation regions above, we can use

Fig. 277 Slice of total pressure coefficient showing separation region on a partially stalled wing.#

The

Fig. 278 Slice of total pressure coefficient showing the growing boundary layer in blue.#

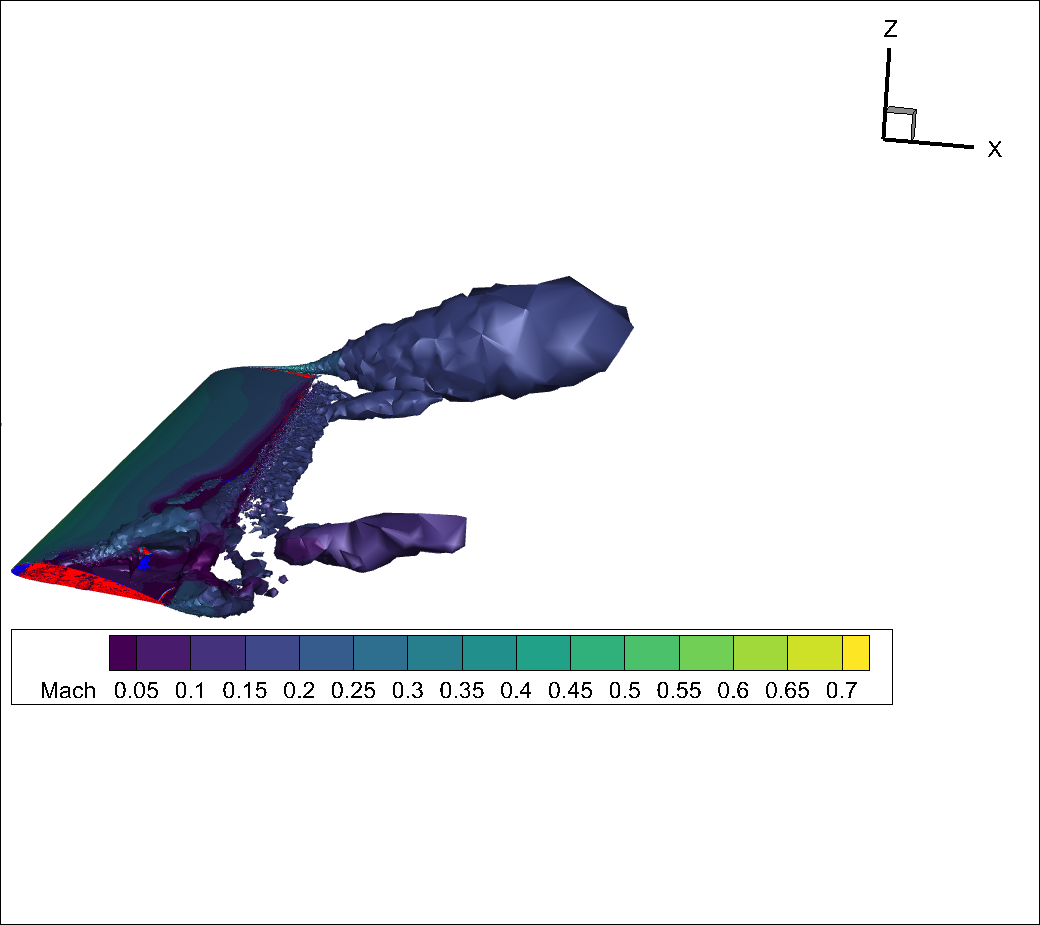

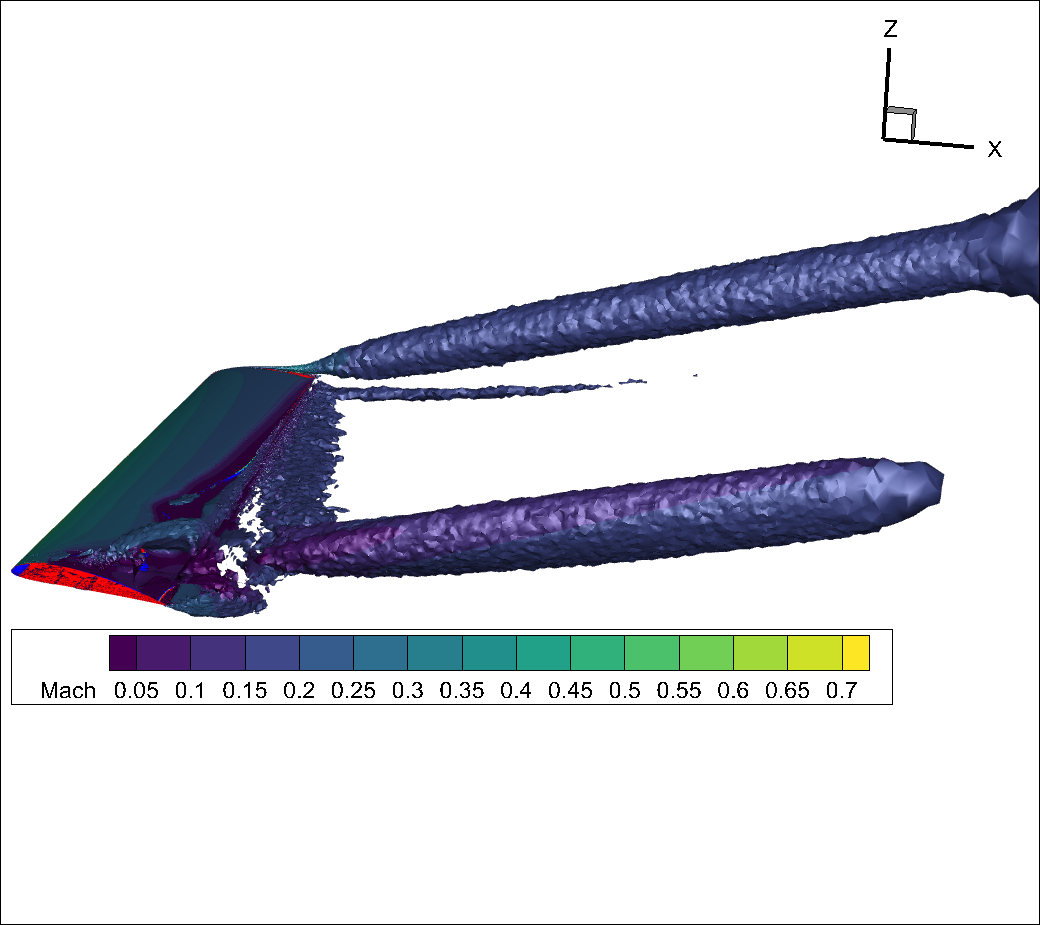

Q-Criterion#

The qcriterion is a very convenient way to visualize vortices in your flowfield. By setting

qcriterion isosurfaces in your volume solution you can easily identify vortices and gain a better understanding of their behavior.

In general, for airplane type simulations, we recommend setting an isosurface value to

Fig. 279 qcriterion isosurface showing strong tip vortex and vortices escaping from the separation region.#

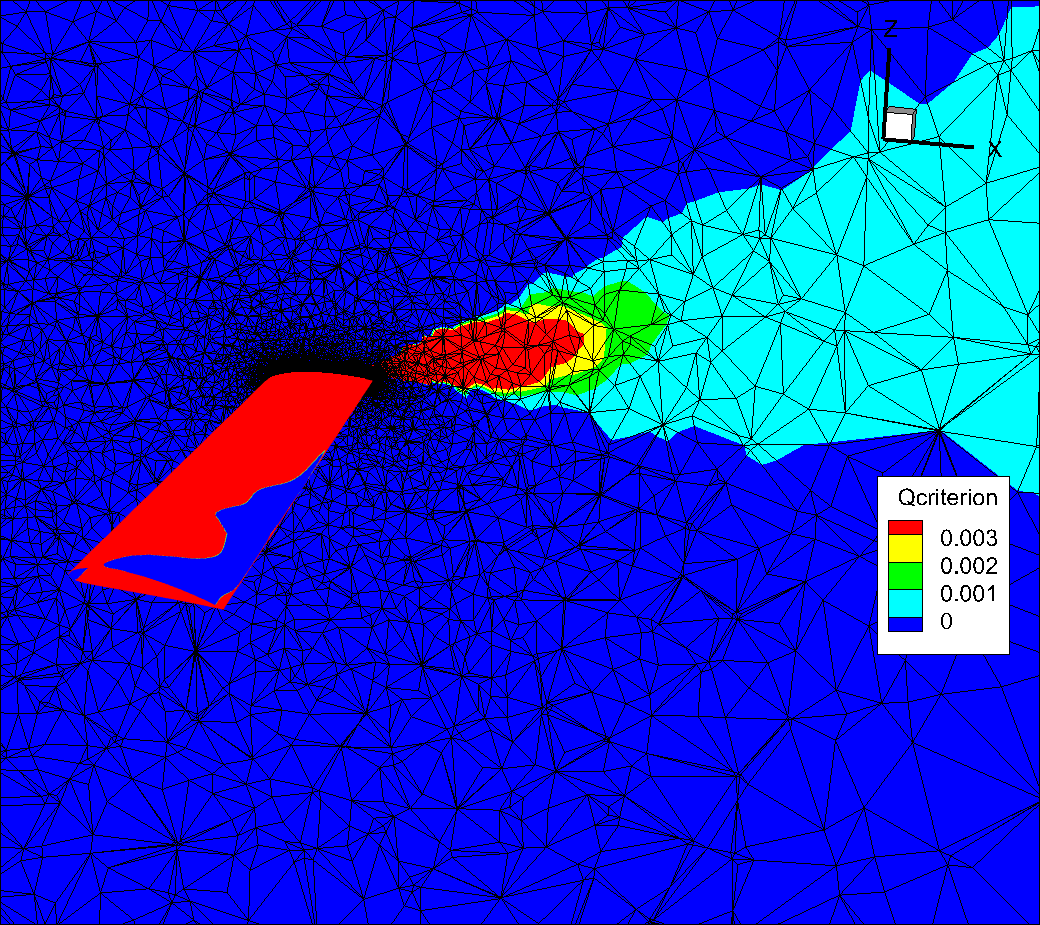

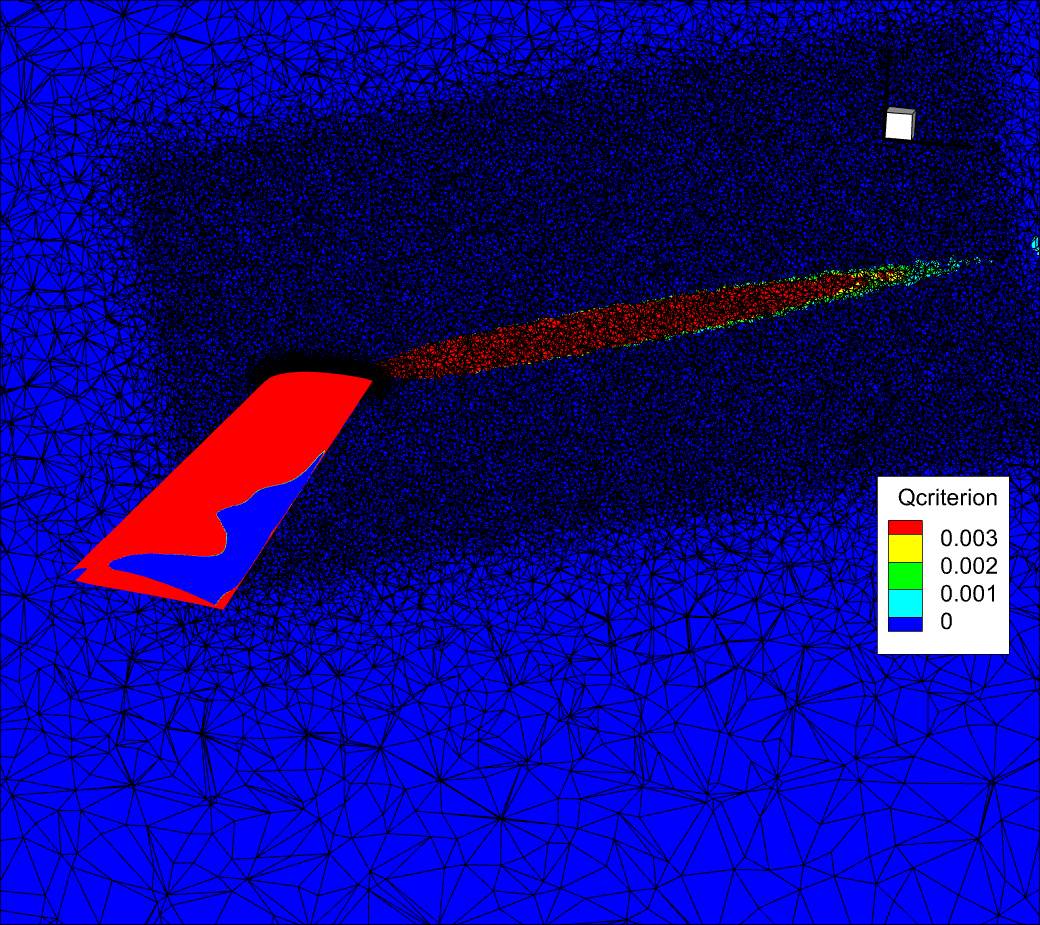

You will notice that, for this test case, because the volume mesh is quite coarse the qcriterion isosurface has a very jagged appearance and the vortex structures dissipate quickly.

Fig. 280 Slice showing the volume mesh. Notice how quickly the mesh coarsens as we move away from the wing and how that affects the qcriterion values.#

If we refine the far field substantially by applying a refinement region we can obtain a much smoother qcriterion isosurface showing improved resolution of the vortices escaping from the tip and from the separation bubble.

Fig. 281 qcriterion isosurface on a finer mesh showing strong tip vortex and vortices escaping from the separation region.#

You will notice that now, for this refined volume mesh, the qcriterion isosurface has a much smoother appearance and the vortex structures propagate much further (i.e., are much less dissipative).

Fig. 282 Slice showing the volume mesh. Finer volume mesh showing the effect on the qcriterion dissipation.#

For more flow images using the qcriterion to visualize vortices please see:

BET Visualization#

An additional option betMetrics in volumeOutput is available to visualize the BET related quantities. This is demonstrated in the BET tutorial.