Waveguide Y junction

Contents

Waveguide Y junction#

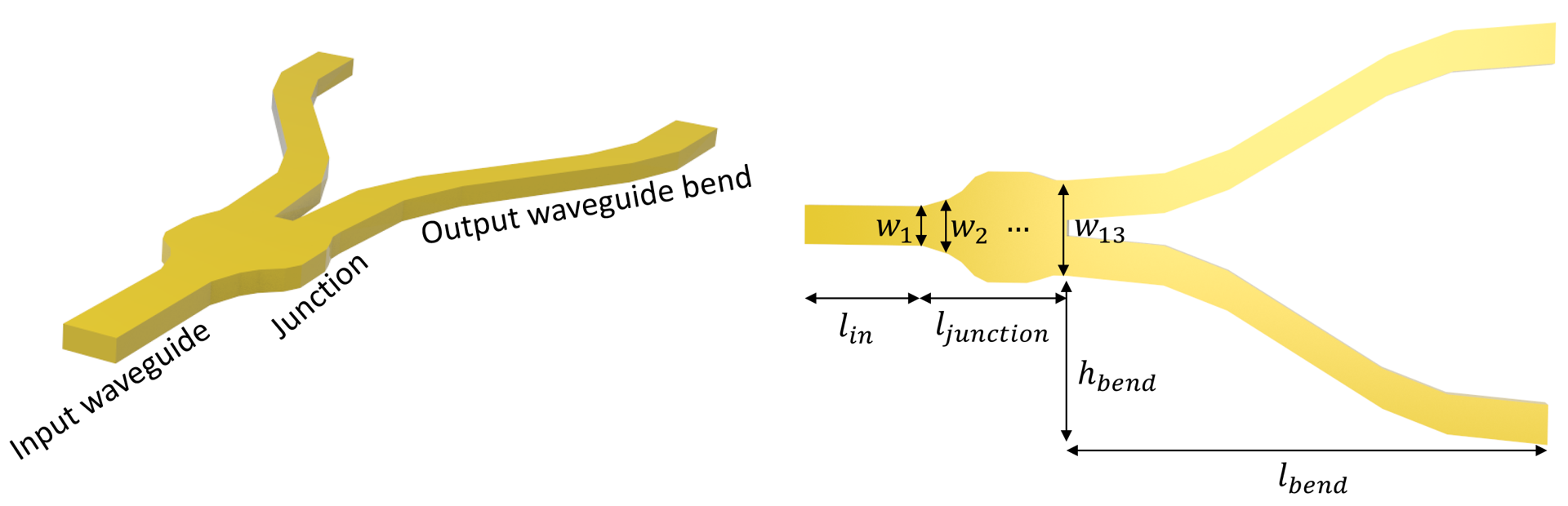

Power splitters such as Y-junctions are widely used in photonic integrated circuits across different applications. When designing a power splitter, we aim to achieve a flat broadband response, low insertion loss, and compact footprint. At the same time, the design needs to comply with the fabrication resolution and tolerance.

In this example, we demonstrate the modeling of a Y-junction for integrated photonics. The designed device shows an average insertion loss below 0.2 dB in the wavelength range of 1500 nm to 1600 nm. At the same time, it has a small footprint. The junction area is smaller than 2 \(\mu m\) by 2 \(\mu m\), much smaller than the typical power splitters based on multimode interference devices. The design is adapted from Yi Zhang, Shuyu Yang, Andy Eu-Jin Lim, Guo-Qiang Lo, Christophe Galland, Tom Baehr-Jones, and Michael Hochberg, “A compact and low loss Y-junction for submicron silicon waveguide,” Opt. Express 21, 1310-1316 (2013).

[1]:

import numpy as np

import matplotlib.pyplot as plt

import gdstk

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins.mode import ModeSolver

Simulation Setup#

Define simulation wavelength range to be 1.5 \(\mu m\) to 1.6 \(\mu m\).

[2]:

lda0 = 1.55 # central wavelength

freq0 = td.C_0 / lda0 # central frequency

ldas = np.linspace(1.5, 1.6, 101) # wavelength range

freqs = td.C_0 / ldas # frequency range

In this model, the Y-junction is made of silicon. The top and bottom claddings are made of silicon oxide. We will model them as non-dispersive materials here.

[3]:

n_si = 3.48 # silicon refractive index

si = td.Medium(permittivity=n_si**2)

n_sio2 = 1.44 # silicon oxide refractive index

sio2 = td.Medium(permittivity=n_sio2**2)

The junction is discretized into 13 segments. Each segment is a tapper with the given widths. The optimum design is obtained by optimizing the 13 width parameters using the Particle Swarm Optimization algorithm. For the sake of simplicity, in this notebook, we skip the optimization procedure and only present the optimized result.

[4]:

t = 0.22 # thickness of the silicon layer

# width of the 13 segments

w1 = 0.5

w2 = 0.5

w3 = 0.6

w4 = 0.7

w5 = 0.9

w6 = 1.26

w7 = 1.4

w8 = 1.4

w9 = 1.4

w10 = 1.4

w11 = 1.31

w12 = 1.2

w13 = 1.2

l_in = 1 # input waveguide length

l_junction = 2 # length of the junction

l_bend = 6 # horizontal length of the waveguide bend

h_bend = 2 # vertical offset of the waveguide bend

l_out = 1 # output waveguide length

inf_eff = 100 # effective infinity

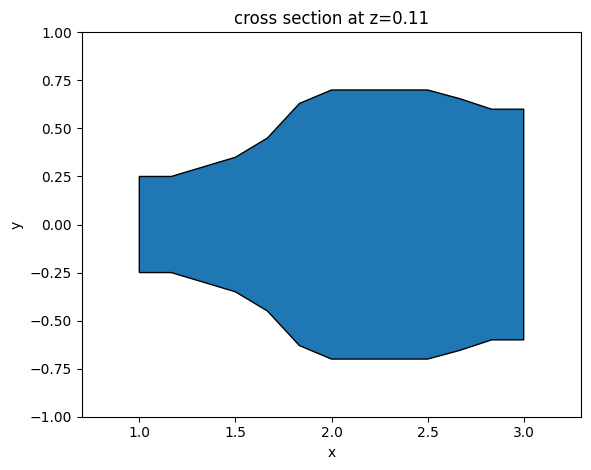

First, define the junction structure by using a PolySlab. The vertices are given by the widths of the segments defined above. If a smooth curve is desirable, one can interpolate the vertices to a finer grid using spline for example.

Before proceeding further to construct other structures, we can use the plot method to inspect the geometry.

[5]:

x = np.linspace(l_in, l_in + l_junction, 13) # x coordinates of the top edge vertices

y = np.array(

[w1, w2, w3, w4, w5, w6, w7, w8, w9, w10, w11, w12, w13]

) # y coordinates of the top edge vertices

# using concatenate to include bottom edge vertices

x = np.concatenate((x, np.flipud(x)))

y = np.concatenate((y / 2, -np.flipud(y / 2)))

# stacking x and y coordinates to form vertices pairs

vertices = np.transpose(np.vstack((x, y)))

junction = td.Structure(

geometry=td.PolySlab(vertices=vertices, axis=2, slab_bounds=(0, t)), medium=si

)

junction.plot(z=t / 2)

plt.show()

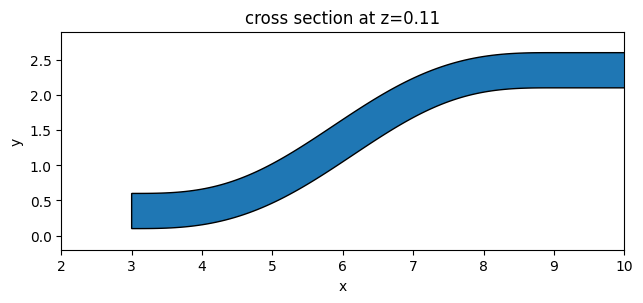

For the output waveguide bends, we use S bend sine waveguides, which are described by the function

\(y = \frac{xh_{band}}{l_{bend}}-\frac{h_{bend}}{2\pi}sin(\frac{2\pi x}{l_{bend}})\).

Different types of bend can also be used here for similar performance. To define the bends, the most convenient way is to use gdstk. First compute the \(x\) and \(y\) coordinates of the bend, then define a FlexPath and add it to a gds cell. The paths in the cell can be converted to Tidy3D PolySlabs using the from_gds method.

[6]:

x_start = l_in + l_junction # x coordinate of the starting point of the waveguide bends

x = np.linspace(

x_start, x_start + l_bend, 100

) # x coordinates of the top edge vertices

y = (

(x - x_start) * h_bend / l_bend

- h_bend * np.sin(2 * np.pi * (x - x_start) / l_bend) / (np.pi * 2)

+ w13 / 2 - w1/2

) # y coordinates of the top edge vertices

# adding the last point to include the straight waveguide at the output

x = np.append(x, inf_eff)

y = np.append(y, y[-1])

# add path to the cell

cell = gdstk.Cell("bends")

cell.add(gdstk.FlexPath(x + 1j * y, w1, layer=1, datatype=0)) # top waveguide bend

cell.add(gdstk.FlexPath(x - 1j * y, w1, layer=1, datatype=0)) # bottom waveguide bend

# define top waveguide bend structure

wg_bend_1 = td.Structure(

geometry=td.PolySlab.from_gds(

cell,

gds_layer=1,

axis=2,

slab_bounds=(0, t),

)[0],

medium=si

)

# define bottom waveguide bend structure

wg_bend_2 = td.Structure(

geometry=td.PolySlab.from_gds(

cell,

gds_layer=1,

axis=2,

slab_bounds=(0, t),

)[1],

medium=si

)

# plot the top waveguide bend to visualize

ax = wg_bend_1.plot(z=t / 2)

ax.set_xlim(2, 10)

plt.show()

Lastly, define the straight input waveguide using [Box]((../_autosummary/tidy3d.Box.html).

[7]:

# straight input waveguide

wg_in = td.Structure(

geometry=td.Box.from_bounds(rmin=(-inf_eff, -w1 / 2, 0), rmax=(l_in, w1 / 2, t)),

medium=si,

)

# the entire model is the collection of all structures defined so far

y_junction = [wg_in, junction, wg_bend_1, wg_bend_2]

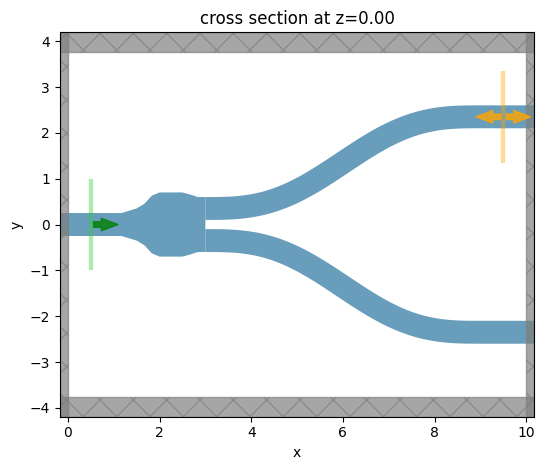

Define the simulation domain. Here we ensure sufficient buffer spacing in each direction. In general, we want to make sure that the structure is at least half a wavelength away from the domain boundaries unless it goes into the PML.

[8]:

Lx = l_in + l_junction + l_out + l_bend # simulation domain size in x direction

Ly = w13 + 2 * h_bend + 1.5 * lda0 # simulation domain size in y direction

Lz = 10 * t # simulation domain size in z direction

sim_size = (Lx, Ly, Lz)

We will use a ModeSource to excite the input waveguide using the fundamental TE mode.

A ModeMonitor is placed at the top output waveguide to measure the transmission. A FieldMonitor is added to the xy plane to visualize the power flow.

[9]:

# add a mode source as excitation

mode_spec = td.ModeSpec(num_modes=1, target_neff=n_si)

mode_source = td.ModeSource(

center=(l_in / 2, 0, t / 2),

size=(0, 4 * w1, 6 * t),

source_time=td.GaussianPulse(freq0=freq0, fwidth=freq0 / 10),

direction="+",

mode_spec=mode_spec,

mode_index=0,

)

# add a mode monitor to measure transmission at the output waveguide

mode_monitor = td.ModeMonitor(

center=(l_in + l_junction + l_bend + l_out / 2, w13 / 2 - w1 / 2 + h_bend, t / 2),

size=(0, 4 * w1, 6 * t),

freqs=freqs,

mode_spec=mode_spec,

name="mode",

)

# add a filed monitor to visualize field distribution at z=t/2

field_monitor = td.FieldMonitor(

center=(0, 0, t / 2), size=(td.inf, td.inf, 0), freqs=[freq0], name="field"

)

Set up the simulation with the previously defined structures, source, and monitors. All boundaries are set to PML to mimic infinite open space. Since the top and bottom claddings are silicon oxide, we will set the medium of the background to silicon oxide.

In principle, we can impose symmetry to reduce the computational load. Since this model is relatively small and quick to solve, we will simply model the whole device without using symmetry.

[10]:

# construct simulation

sim = td.Simulation(

center=(Lx / 2, 0, 0),

size=sim_size,

grid_spec=td.GridSpec.auto(min_steps_per_wvl=30, wavelength=lda0),

structures=y_junction,

sources=[mode_source],

monitors=[mode_monitor, field_monitor],

run_time=5e-13,

boundary_spec=td.BoundarySpec.all_sides(boundary=td.PML()),

medium=sio2,

)

sim.plot(z=0)

plt.show()

Before submitting the simulation to the server, it is a good practice to visualize the mode profile at the ModeSource to ensure we are launching the fundamental TE mode. To do so, we will use the ModeSolver plugin, which solves for the mode profile on your local computer.

[11]:

mode_solver = ModeSolver(

simulation=sim,

plane=td.Box(center=mode_source.center, size=mode_source.size),

mode_spec=mode_spec,

freqs=[freq0],

)

mode_data = mode_solver.solve()

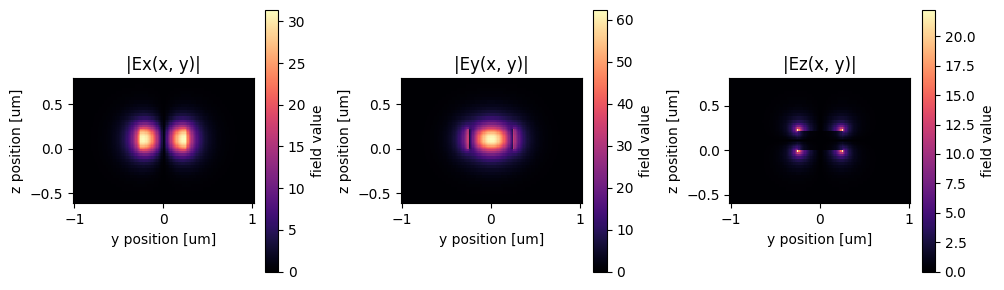

Visualize the mode profile. We confirm that we are exciting the waveguide with the fundamental TE mode.

[12]:

f, (ax1, ax2, ax3) = plt.subplots(1, 3, tight_layout=True, figsize=(10, 3))

abs(mode_data.Ex.isel(mode_index=0)).plot(x="y", y="z", ax=ax1, cmap="magma")

abs(mode_data.Ey.isel(mode_index=0)).plot(x="y", y="z", ax=ax2, cmap="magma")

abs(mode_data.Ez.isel(mode_index=0)).plot(x="y", y="z", ax=ax3, cmap="magma")

ax1.set_title("|Ex(x, y)|")

ax1.set_aspect("equal")

ax2.set_title("|Ey(x, y)|")

ax2.set_aspect("equal")

ax3.set_title("|Ez(x, y)|")

ax3.set_aspect("equal")

plt.show()

Now that we verified all the settings, we are ready to submit the simulation job to the server.

[13]:

job = web.Job(simulation=sim, task_name="y_junction", verbose=True)

sim_data = job.run(path="data/simulation_data.hdf5")

Result Visualization#

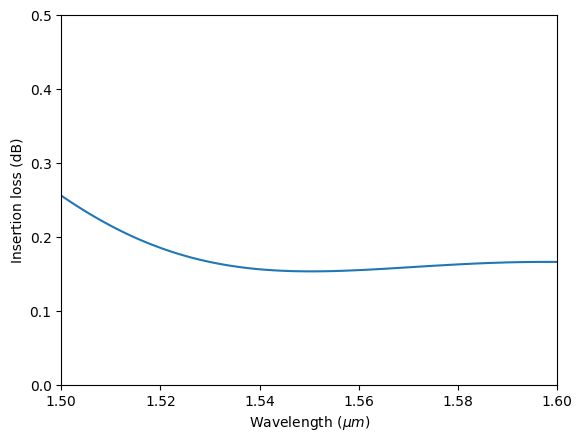

After the simulation is complete, we first inspect the insertion loss. Within this wavelength range, we see that the insertion loss is generally below 0.2 dB.

[14]:

# extract the transmission data from the mode monitor

amp = sim_data["mode"].amps.sel(mode_index=0, direction="+")

T = np.abs(amp)**2

plt.plot(ldas, -10 * np.log10(2 * T))

plt.xlim(1.5, 1.6)

plt.ylim(0, 0.5)

plt.xlabel("Wavelength ($\mu m$)")

plt.ylabel("Insertion loss (dB)")

plt.show()

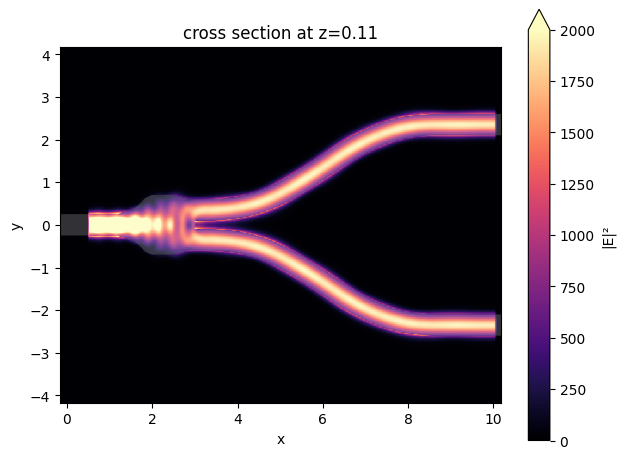

We can also visualize the field distribution. Here we can see the interference in the junction while no visible higher order modes are excited at the output waveguides.

[15]:

sim_data.plot_field(

field_monitor_name="field", field_name="E", val="abs^2", f=freq0, vmin=0, vmax=2000

)

plt.show()

[ ]: