Biosensor grating

Contents

Biosensor grating#

Bragg gratings are structures which involve a periodic variation in the refractive index or geometry of waveguide, so that certain frequencies of light are reflected off the grating while others are transmitted.

Since gratings can be designed to be extremely sentitive, one possible application they have is to detect the presence of foreign molecules. If particles such as biomolecules are deposited on the device, it will no longer have the same reflective properties in the band of frequencies for which it was designed. Therefore, carefully-designed Bragg gratings can be used as biosensors.

In this example, an optical biosensor grating is modeled to detect the presence of biomolecules. The grating is designed to be reflective over a narrow band around its resonant frequency which is modified by the presence of a biomolecule.

Reference: Brian Cunningham, Bo Lin, Jean Qiu, Peter Li, Jane Pepper, Brenda Hugh, “A plastic colorimetric resonant optical biosensor for multiparallel detection of label-free biochemical interactions,” Sensors and Actuators B 85 (2002), DOI: 10.1016/S0925-4005(02)00111-9

[1]:

# basic imports

import numpy as np

import matplotlib.pylab as plt

# Tidy3D imports

import tidy3d as td

Structure Setup#

Create the grating geometry.

[2]:

# materials

Si3N4 = td.Medium(permittivity=2.05**2)

epoxy = td.Medium(permittivity=1.5**2)

background = td.Medium(permittivity=1.333**2)

# set basic geometric parameters (units in microns)

nm = 1e-3

period = 550 * nm

grating_fill_factor = 0.5

grating_height = 200 * nm

film_height = 120 * nm

epoxy_height = 380 * nm

monitor_distance = 1.0

monitor_gap = 0.1

# the epoxy layer top surface is at z=0

sim_center = (0, 0, 0.5 * (grating_height + film_height - epoxy_height))

sim_size = (

period,

0,

epoxy_height + grating_height + film_height + 2 * (monitor_distance + monitor_gap),

)

# wavelength / frequency setup

wavelength_min = 770 * nm

wavelength_max = 900 * nm

freq_min = td.C_0 / wavelength_max

freq_max = td.C_0 / wavelength_min

freq0 = (freq_min + freq_max) / 2.0

fwidth = freq_max - freq_min

run_time = 10e-12

# epoxy layer

epoxy_layer = td.Structure(

geometry=td.Box(

center=[0.0, 0.0, -0.5 * epoxy_height],

size=[td.inf, td.inf, epoxy_height],

),

medium=epoxy,

name="epoxy_layer",

)

# bottom Si3N4 film layer

bottom_film = td.Structure(

geometry=td.Box(

center=[0.0, 0.0, 0.5 * film_height],

size=[td.inf, td.inf, film_height],

),

medium=Si3N4,

name="bottom_film",

)

# epoxy grating teeth (partially covers the film layer)

grating_teeth = td.Structure(

geometry=td.Box(

center=[0.0, 0.0, 0.5 * grating_height],

size=[period * grating_fill_factor, td.inf, grating_height],

),

medium=epoxy,

name="grating_teeth",

)

# top Si3N4 film layer

top_film = td.Structure(

geometry=td.Box(

center=[0.0, 0.0, grating_height + 0.5 * film_height],

size=[period * grating_fill_factor, td.inf, film_height],

),

medium=Si3N4,

name="top_film",

)

# the order her matters, because the teeth must override the bottom film layer

geometry = [epoxy_layer, bottom_film, grating_teeth, top_film]

# boundary conditions: the simulation is periodic in the x-y plane, and simulates

# an infinite domain along z

boundary_spec = td.BoundarySpec(

x=td.Boundary.periodic(),

y=td.Boundary.periodic(),

z=td.Boundary.pml(),

)

# grid specification

grid_spec = td.GridSpec.auto(min_steps_per_wvl=30)

Source Setup#

Create the plane wave source which excites the structure from underneath.

[3]:

source_time = td.GaussianPulse(freq0=freq0, fwidth=fwidth)

source = td.PlaneWave(

center=[0, 0, -(epoxy_height + monitor_distance - monitor_gap)],

size=[td.inf, td.inf, 0.0],

source_time=source_time,

pol_angle=0,

direction="+",

)

Monitor Setup#

Create field and flux monitors to measure reflecting and transmitted flux.

[4]:

# create field monitor

monitor_xz = td.FieldMonitor(

center=sim_center,

size=[td.inf, 0, td.inf],

freqs=[freq0],

name="fields_xz",

)

# create flux monitors

freqs = np.linspace(freq_min, freq_max, 1000)

monitor_flux_refl = td.FluxMonitor(

center=[0, 0, -(epoxy_height + monitor_distance)],

size=[td.inf, td.inf, 0.0],

freqs=freqs,

name="flux_refl",

)

monitor_flux_tran = td.FluxMonitor(

center=[0, 0, grating_height + film_height + monitor_distance],

size=[td.inf, td.inf, 0.0],

freqs=freqs,

name="flux_tran",

)

monitors = [monitor_xz, monitor_flux_refl, monitor_flux_tran]

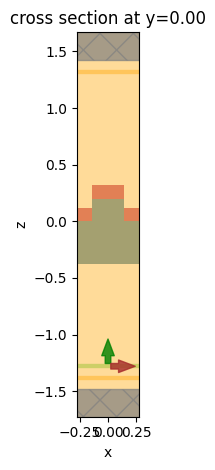

Create Simulation#

The final simulation object is created and visualized.

[5]:

# create the simulation

sim = td.Simulation(

center=sim_center,

size=sim_size,

grid_spec=grid_spec,

structures=geometry,

sources=[source],

monitors=monitors,

run_time=run_time,

boundary_spec=boundary_spec,

medium=background,

shutoff=1e-6,

)

# plot the simulation domain

sim.plot(y=0)

plt.show()

Run Simulation#

[6]:

# run simulation

import tidy3d.web as web

sim_data = web.run(sim, task_name="biosensor", path="data/biosensor.hdf5", verbose=True)

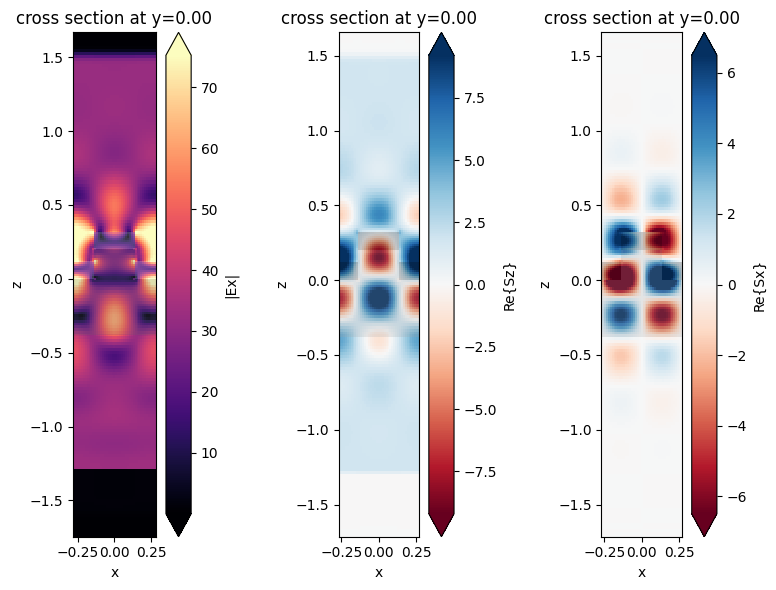

Plot Fields#

The frequency-domain fields recorded are plotted at the center frequency in an xz plane. The resonance can be clearly seen in the power flow pattern shown by the Poynting vector plots.

[7]:

fig, ax = plt.subplots(1, 3, figsize=(8, 6), tight_layout=True)

sim_data.plot_field("fields_xz", field_name="Ex", val="abs", f=freq0, ax=ax[0])

sim_data.plot_field("fields_xz", field_name="Sz", val="real", f=freq0, ax=ax[1])

sim_data.plot_field("fields_xz", field_name="Sx", val="real", f=freq0, ax=ax[2])

plt.show()

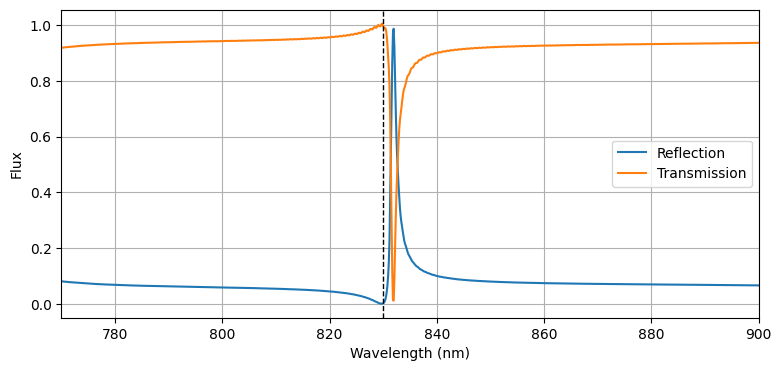

Plot Transmission and Reflection#

To see the effectiveness of the grating, we can compute and plot the reflection and transmission via the flux measured by the flux monitor. As the plot shows, the structure is highly reflective in a narrow frequency range around the design frequency, allowing one to detect small variations in the frequency response due to the presence of biological materials. The vertical dashed line shows the wavelength used in the previous plots.

[8]:

transmission = sim_data["flux_tran"].flux

reflection = -sim_data["flux_refl"].flux

fig, ax = plt.subplots(figsize=(9, 4))

ax.plot(td.C_0 / freqs * 1e3, reflection, label="Reflection")

ax.plot(td.C_0 / freqs * 1e3, transmission, label="Transmission")

# wavelength for the field plots

ax.axvline(td.C_0 / freq0 * 1e3, ls="--", color="k", lw=1)

ax.set(

xlabel="Wavelength (nm)",

ylabel="Flux",

xlim=(wavelength_min * 1e3, wavelength_max * 1e3),

)

ax.legend()

ax.grid()

plt.show()