Inverse Designed Grating Coupler¶

In this notebook, we demonstrate an example of fabrication-aware inverse design using PhotonForge in conjunction with Tidy3D’s inverse design framework.

PhotonForge is an end-to-end photonic design automation platform that accelerates photonic integrated circuit development by seamlessly integrating simulation tools, layout editing, circuit-level system modeling, and foundry PDKs into one unified workflow. Tidy3D’s inverse design framework enables efficient computation of the derivative of a figure of merit (such as transmission) with respect to any number of design parameters. Together, these tools provide a powerful and streamlined design automation workflow for optimizing photonic components.

In this example, we use PhotonForge and inverse design to optimize a grating coupler. The initial grating coupler structure is based on this PhotonForge example, which follows the design presented in [1].

For additional examples of inverse-designed grating couplers, see this and this Tidy3D notebook.

For a broader overview of inverse design in Tidy3D, refer to the Inverse Design Quickstart. More in-depth examples are also available here.

References

Frederik Van Laere, Tom Claes, Jonathan Schrauwen, Stijn Scheerlinck, Wim Bogaerts, Dirk Taillaert, Liam O’Faolain, Dries Van Thourhout, Roel Baets, “Compact Focusing Grating Couplers for Silicon-on-Insulator Integrated Circuits,” IEEE Photonics Technology Letters, 2007 19 (23), 1919–1921, doi: 10.1109/LPT.2007.908762

The general workflow for this notebook is summarized below:

[1]:

from functools import partial

import autograd as ag

import autograd.numpy as np # Important to import autograd's numpy module for tracing derivatives

import optax

import photonforge as pf

import tidy3d as td

from matplotlib import pyplot as plt

from tidy3d.plugins.autograd import smooth_min

# Set the default PhotonForge -> Tidy3D mesh refinement

# We are running 2D simulations, so this can be set rather high

pf.config.default_mesh_refinement = 30.0

Technology Setup¶

In the first part of this notebook, we set up the technology stack.

The technology used in the reference work [1] is similar to PhotonForge’s basic technology, with two key differences: the slab thickness and the absence of the top cladding.

To emulate the 70 nm etch depth from the reference design, we set the slab_thickness to 150 nm:

[2]:

tech = pf.basic_technology(slab_thickness=0.15)

pf.config.default_technology = tech

We can view the layers and extrusions provided by the technology

[3]:

tech.layers

[3]:

| Name | Layer | Description | Color | Pattern |

|---|---|---|---|---|

| WG_CLAD | (1, 0) | Waveguide clad | #9da6a218 | . |

| WG_CORE | (2, 0) | Waveguide core | #6db5dd18 | / |

| SLAB | (3, 0) | Slab region | #8851ad18 | : |

| TRENCH | (4, 0) | Deep-etched trench for chip…… facets | #535e5918 | + |

| METAL | (5, 0) | Metal layer | #b8a18b18 | \ |

[4]:

tech.extrusion_specs

[4]:

| # | Mask | Limits (μm) | Sidewal (°) | Opt. Medium | Elec. Medium |

|---|---|---|---|---|---|

| 0 | 'WG_CORE' | 0, 0.22 | 0 | PoleResidue(frequency_range=……(21413747041496.2, 249827048817455.7), poles=((6241549589084091j, -3.3254308736142404e+16j),), eps_inf=1.0) | Medium(permittivity=12.3) |

| 1 | 'SLAB' | 0, 0.15 | 0 | PoleResidue(frequency_range=……(21413747041496.2, 249827048817455.7), poles=((6241549589084091j, -3.3254308736142404e+16j),), eps_inf=1.0) | Medium(permittivity=12.3) |

| 2 | 'METAL' | 1.72, 2.22 | 0 | PoleResidue(frequency_range=……(154771532266391.3, 1595489398616285.2), poles=(((-1252374269166904.5-7829718683182146j), (-660427953437394.4+2056312746029814.8j)), ((-500398492478025.6-3123892988543211j), (2348376270614990-1390125983450377.5j)), ((-775228900492209.9-1254493598977193.5j), (-7078896427414573-1.007782055107454e+16j)), ((-92770480154285.34-1365410212347161.2j), (323897486922091.44+93507890692118.31j)), ((-8965554692589.553-256329468465111.16j), (1.6798480681493582e+16+2.8078798578850288e+17j))), eps_inf=1.0) | PEC |

| 3 | 'TRENCH' | -inf, inf | 0 | Medium() | Medium() |

Unfortunately, there is no direct argument to remove the top cladding in the basic technology, because both the top and bottom media are defined by the background medium. Additionally, setting the top cladding thickness to zero is not an option, since it is used internally to define the port dimensions.

A better approach is to add a new extrusion specification to the technology. This specification will create an extra air volume above the substrate with infinite vertical extent. We can achieve this using the insert_extrusion_spec method:

[5]:

# An empty mask covers the whole device bounds

air_extrusion = pf.ExtrusionSpec(

pf.MaskSpec(), td.Medium(permittivity=1.0, name="air"), limits=(0, pf.Z_INF)

)

# Insert air volume first, so that all core extrusions override the air clad

tech.insert_extrusion_spec(0, air_extrusion)

# Print the updated extrusion specs

tech.extrusion_specs

[5]:

| # | Mask | Limits (μm) | Sidewal (°) | Opt. Medium | Elec. Medium |

|---|---|---|---|---|---|

| 0 | () | 0, inf | 0 | air | air |

| 1 | 'WG_CORE' | 0, 0.22 | 0 | PoleResidue(frequency_range=……(21413747041496.2, 249827048817455.7), poles=((6241549589084091j, -3.3254308736142404e+16j),), eps_inf=1.0) | Medium(permittivity=12.3) |

| 2 | 'SLAB' | 0, 0.15 | 0 | PoleResidue(frequency_range=……(21413747041496.2, 249827048817455.7), poles=((6241549589084091j, -3.3254308736142404e+16j),), eps_inf=1.0) | Medium(permittivity=12.3) |

| 3 | 'METAL' | 1.72, 2.22 | 0 | PoleResidue(frequency_range=……(154771532266391.3, 1595489398616285.2), poles=(((-1252374269166904.5-7829718683182146j), (-660427953437394.4+2056312746029814.8j)), ((-500398492478025.6-3123892988543211j), (2348376270614990-1390125983450377.5j)), ((-775228900492209.9-1254493598977193.5j), (-7078896427414573-1.007782055107454e+16j)), ((-92770480154285.34-1365410212347161.2j), (323897486922091.44+93507890692118.31j)), ((-8965554692589.553-256329468465111.16j), (1.6798480681493582e+16+2.8078798578850288e+17j))), eps_inf=1.0) | PEC |

| 4 | 'TRENCH' | -inf, inf | 0 | Medium() | Medium() |

Grating Coupler Adjoint Optimization¶

Next, let’s set up the grating coupler adjoint optimization. In this workflow, we use PhotonForge to construct the initial Tidy3D model. The benefit of this approach is that PhotonForge automatically generates Tidy3D geometry layers based on the technology stack and extrusion specifications. PhotonForge creates the initial simulation setup, which we will then modify for the adjoint optimization.

Background Simulation Setup with PhotonForge¶

We begin by creating a starting simulation using PhotonForge. This simulation includes all structures that remain fixed during optimization—such as the background layer stack (input waveguide, cladding oxide, and air), the Gaussian beam source, and the waveguide monitor.

To build the simulation, we define a PhotonForge component that:

Draws the background structures using the specified technology stack.

Generates an initial Tidy3D simulation model, which we will later update for adjoint optimization.

Below are the setup parameters for the component:

Note: Since we are working in 2D, the wg_width represents the extent of the waveguide in the invariant y-direction and does not impact the actual guided mode profile. The simulation will be carried out in the x–z plane.

[6]:

# Setup parameters

wg_width = 6 # This is arbitrary because the simulation is 2D

wg_length = 30

fiber_angle = 10

fiber_translation = 3

waist_radius = 6.0

gaussian_port_height = 0.5

# Define the gaussian port input vector based on the fiber angle

sin_angle = np.sin(fiber_angle / 180 * np.pi)

cos_angle = np.cos(fiber_angle / 180 * np.pi)

input_vector = (-sin_angle, 0, -cos_angle)

Next, we create the background PhotonForge component and add the input waveguide as a rectangle.

[7]:

# Create an empty Photonforge component

background = pf.Component()

# Add the waveguide layer

wg = pf.Rectangle((0, -wg_width / 2), (wg_length, wg_width / 2))

background.add("WG_CORE", wg)

[7]:

We then add two ports: one Gaussian port positioned above the center of the grating, and another at the input of the waveguide.

The Gaussian port will be converted to a Gaussian source, and the waveguide port will be converted to a mode monitor when PhotonForge generates the Tidy3D simulation.

[8]:

# Add the waveguide port

input_wg_portspec = pf.PortSpec(

"input wg",

width=wg_width,

limits=tech.ports["Strip"].limits,

num_modes=1,

target_neff=3.5,

path_profiles={(wg_width, 0, tech.layers["WG_CORE"].layer)},

)

background.add_port(pf.Port((0, 0), 0, input_wg_portspec))

# Add the fiber (gaussian) port

gaussian_port_center = (wg_length / 2 + fiber_translation, 0, gaussian_port_height)

background.add_port(

pf.GaussianPort(

gaussian_port_center,

input_vector,

waist_radius,

polarization_angle=90,

field_tolerance=1e-2,

)

)

[8]:

'P1'

We can now see that the two ports have been added to the component:

[9]:

background

[9]:

Now we add a Tidy3D simulation model to the component. This model will generate the initial Tidy3D simulation, which serves as the starting point for the adjoint optimization.

[10]:

# Add a Tidy3D simulation model to the component

background.add_model(pf.Tidy3DModel(), "Tidy3D")

[10]:

'Tidy3D'

From the model we just added to the component, we extract the base simulation for optimization.

PhotonForge generates one simulation for each source port. Here, we select the simulation labeled "P1@0", which corresponds to port P1 being used as the excitation source. This is the simulation we will modify during the optimization process.

[11]:

wavelengths = np.linspace(1.5, 1.6, 21)

sims = background.models["Tidy3D"].get_simulations(background, pf.C_0 / wavelengths)

# Select the simulation where port P1 is used as the source

basesim = sims["P1@0"] # This will be the base simulation that we work with

Let’s view this simulation:

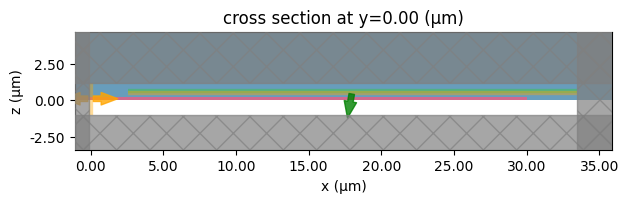

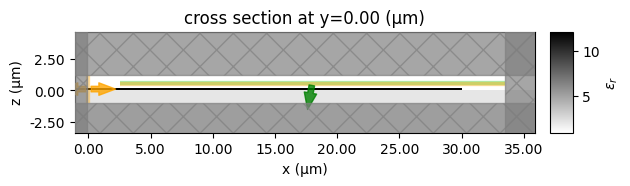

[12]:

basesim.plot(y=0)

basesim.plot_eps(y=0)

plt.show()

We can see that PhotonForge has automatically generated the simulation contains background structures for this technology stack, and has added a Gaussian beam source (green) and a waveguide mode monitor (orange).

Grating Coupler Simulation¶

Now that we have our base simulation with all static structures, we can modify it to include the grating region and run 2D grating simulations.

First, we convert the base simulation from 3D to 2D. We also remove the field monitor placed below the Gaussian source, as it is not required for the optimization (PhotonForge adds it automatically for S-parameter calculations).

[13]:

# Update the simulation size so that it is 2D

size = (basesim.size[0], 0, basesim.size[2])

# Update the boundary spec for 2D simulations

boundary_spec = basesim.boundary_spec.updated_copy(

y=td.Boundary(minus=td.Periodic(), plus=td.Periodic()),

)

basesim = basesim.updated_copy(

size=size,

boundary_spec=boundary_spec,

)

The size of the simulation is now two dimensional:

[14]:

print(basesim.size)

(33.534, 0.0, 2.222)

Next, we add in the grating coupler structure. Below are the starting parameters for our grating coupler, taken from [1].

[15]:

period = 0.63 # Grating period in microns

gc_len = 15.5 # Total grating length in microns

ncells = int(round(gc_len / period)) # Number of grating periods

fill_factor = 0.5 # Filling factor at each period

# Initial grating structure: uniform fill factor

gc_widths = np.ones(shape=ncells) * period * fill_factor

gc_gaps = period - gc_widths

To determine the z-bounds of the grating etch, we extract the slab_thickness and core_thickness from the technology definition.

The etch region spans from the top of the slab to the top of the waveguide core.

[16]:

# Get thickness values from the technology's parametric definition

slab_thickness = tech.parametric_kwargs["slab_thickness"]

core_thickness = tech.parametric_kwargs["core_thickness"]

# Define core and slab z-bounds (assume waveguide core starts at z = 0)

corebounds = (0, core_thickness)

slabbounds = (0, slab_thickness)

# The etched region spans from top of slab to top of core

etch_zbounds = (slabbounds[1], corebounds[1])

Next, we define a function that adds the grating teeth to the simulation. This function constructs a 2D grating geometry using the specified gap and width arrays, and appends it to the base simulation.

[17]:

def gc_sim(

gc_gaps: np.ndarray,

gc_widths: np.ndarray,

basesim: td.Simulation = basesim,

gc_startx: float = 5,

):

"""Returns a 2D grating simulation for optimization.

Parameters

----------

gc_gaps : np.ndarray

Widths of the partially etched regions.

gc_widths : np.ndarray

Widths of the unetched regions.

basesim : td.Simulation

Base simulation to update.

gc_startx : float

x-coordinate where the grating starts.

"""

# Add the grating teeth to the simulation

grating_structures = []

cx = gc_startx

for w, g in zip(gc_widths, gc_gaps):

cx += g / 2

grating_structures.append(

td.Structure(

geometry=td.Box.from_bounds(

rmin=(cx - g / 2, -td.inf, etch_zbounds[0]),

rmax=(cx + g / 2, td.inf, etch_zbounds[1]),

),

medium=td.Medium(permittivity=1.0),

)

)

cx += g / 2 + w

# Combine with existing structures

structures = list(basesim.structures) + grating_structures

# Etch away the remaining waveguide layer after the grating

structures.append(

td.Structure(

geometry=td.Box.from_bounds(

rmin=(cx, -td.inf, corebounds[0]),

rmax=(1e3, td.inf, corebounds[1]),

),

medium=td.Medium(permittivity=1.0),

)

)

return basesim.updated_copy(structures=structures)

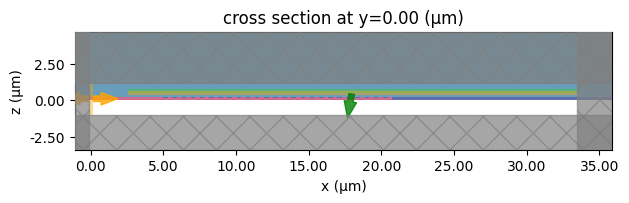

Let’s test the grating coupler simulation to ensure it is working correctly. We start by visualizing the simulation with the grating structure added.

[18]:

# test gc sim

testsim = gc_sim(

gc_gaps,

gc_widths,

)

testsim.plot(y=0)

plt.show()

The source position is likely not optimal for high coupling efficiency, but we can run the simulation to ensure there are no setup errors.

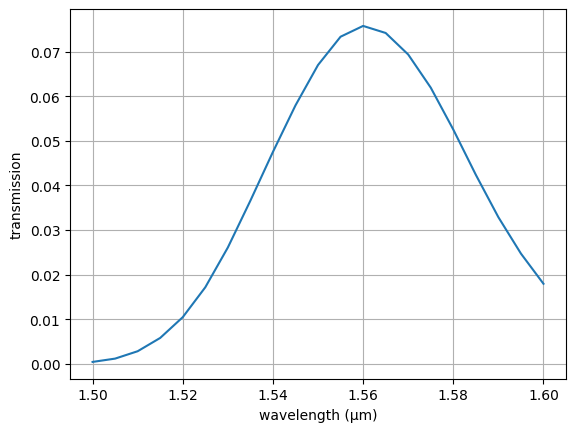

[19]:

# Run the simulation

sim_data = td.web.run(testsim, task_name="testgc", path="simdata/data.hdf5", verbose=False)

# Plot transmission from the Gaussian source to the waveguide port

amps = sim_data["P0"].amps.sel(direction="-")

T = amps.abs**2

f, ax = plt.subplots()

ax.plot(td.C_0 / T.f, T)

ax.set_xlabel("wavelength (µm)")

ax.set_ylabel("transmission")

ax.grid()

The initial simulation looks correct.

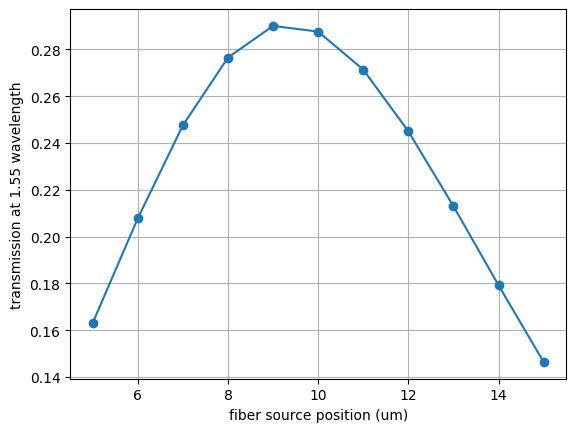

Now let’s sweep the source position and find the position for the best coupling.

[20]:

# sweep source position for best coupling

fiber_pos = np.linspace(5, 15, 11)

# Generate simulations with updated fiber source positions

sims = []

for fpos in fiber_pos:

source = testsim.sources[0]

source = source.updated_copy(center=(fpos, source.center[1], source.center[2]))

sims.append(testsim.updated_copy(sources=[source]))

# Consolidate simulations into a dict for passing to td.web.run_async

gcsims = {f"fiber_pos{fpos}": sim for fpos, sim in zip(fiber_pos, sims)}

# Run the batch of simulations.

batchdata = td.web.run_async(gcsims, path_dir="simdata", verbose=False)

[21]:

# Get transmission at the center wavelength vs. source position

centerwl = 1.55

T_centerwl = []

for key, simdata in batchdata.items():

amps = simdata["P0"].amps.sel(direction="-")

T = amps.abs**2

T_centerwl.append(T.interp(f=td.C_0 / centerwl).data[0])

[22]:

f, ax = plt.subplots()

ax.plot(fiber_pos, T_centerwl, "-o")

ax.set_xlabel("fiber source position (um)")

ax.set_ylabel(f"transmission at {centerwl} wavelength")

ax.grid()

plt.show()

It looks like a good source position is around 9 µm. Let’s update the base simulation with this optimal source position. With that in place, we’re ready to proceed with adjoint optimizations.

[23]:

# update source position

best_fiber_pos = fiber_pos[np.argmax(T_centerwl)]

source = basesim.sources[0]

source = source.updated_copy(center=(best_fiber_pos, source.center[1], source.center[2]))

basesim = basesim.updated_copy(sources=[source])

Adjoint Optimization¶

We start by defining an objective function to optimize. In this case, the objective is to maximize the worst-case transmission within a specified wavelength range.

To ensure compatibility with gradient-based optimization, we use the smooth_min() function, which provides a differentiable approximation of the minimum value across a set. Differentiability is essential for gradient descent methods to work effectively.

[24]:

def worstloss(simdata, wl_range):

"""Returns the worst transmission across measured frequencies from the monitor"""

freqrange = td.C_0 / np.array(wl_range)

amps = simdata["P0"].amps.sel(direction="-", f=slice(freqrange[0], freqrange[1])).data

T = np.abs(amps) ** 2

return smooth_min(T, tau=1e-2)

To use this objective function with Autograd—which handles differentiation through general Python code—we must define the optimization parameters as a single array and pass them as positional arguments to the objective function. For an overview of how Autograd fits into the Tidy3D inverse design pipeline, see this article.

Before defining the objective function, we’ll create two helper functions to convert between a design dictionary and a flat NumPy array. This will make it easier to manage the design parameters both inside and outside the optimization loop.

[25]:

def design_to_array(design: dict[str, np.ndarray]) -> tuple[np.ndarray, tuple[int, int]]:

"""Converts design parameters into a single array"""

gc_gaps = design["gc_gaps"]

gc_widths = design["gc_widths"]

array = np.hstack([gc_gaps, gc_widths])

lengths = (

len(gc_gaps),

len(gc_widths),

)

return array, lengths

def array_to_design(array: np.ndarray, lengths: tuple[int, int]) -> dict[str, np.ndarray]:

"""Converts array back to design parameters"""

len_gaps, len_widths = lengths

idx = 0

design = {}

design["gc_gaps"] = array[idx : idx + len_gaps]

idx += len_gaps

design["gc_widths"] = array[idx : idx + len_widths]

return design

Now we define the objective function, which wraps the loss function in a form compatible with Autograd. The function:

Accepts the optimization parameters as a single NumPy array and converts them back to a design dictionary.

Creates and runs a simulation using those design parameters.

Computes and returns the objective value (e.g., worst-case transmission loss).

[26]:

def objective(params_array: np.ndarray, param_lengths, wl_range):

"""The objective function for optimization. Creates the simulation, and returns the loss."""

# first convert the parameter array to a dictionary for passing to the simulation maker

design = array_to_design(params_array, param_lengths)

# then create and run the simulation

sim = gc_sim(**design, basesim=basesim)

simdata = td.web.run(sim, task_name="gcopt", path="simdata/gc.hdf5", verbose=False)

# finally return the objective value

return worstloss(simdata, wl_range=wl_range)

In a real photonic integrated circuit (PIC) platform, there are minimum feature size constraints. These include:

Minimum line width: the smallest allowable feature width (e.g., for etched or deposited material).

Minimum space (gap): the smallest allowable spacing between features.

We define these constraints and enforce them inside the optimization loop using parameter clipping. Clipping ensures that no design parameter violates the minimum line or gap rules.

[27]:

min_line = 0.15

min_space = 0.2

def minfeat_cliparray(design, min_line=min_line, min_space=min_space):

"""This function returns a single array of minimum line and space for clipping."""

_, param_lengths = design_to_array(design)

min_spaces = min_space * np.ones(shape=param_lengths[0])

min_lines = min_line * np.ones(shape=param_lengths[1])

return np.concatenate((min_spaces, min_lines))

Now we assemble the various components into the main optimization loop.

In addition to the starting design and objective function, we also define hyperparameters such as the number of optimization steps, learning rate, and the optimizer. We use the Adam algorithm from the Optax package, which is well-suited for gradient-based optimization.

Tidy3D’s adjoint solver—combined with Autograd—automatically evaluates gradients via the chain rule through general Python code. The optimizer (Optax in this case) then updates the parameters at each step using these gradients.

[33]:

# The wavelength range to optimize for

wl_range = (1.545, 1.555)

# Optimization parameters

learning_rate = 1e-2

num_steps = 40

# The starting grating design

design0 = {

"gc_gaps": gc_gaps,

"gc_widths": gc_widths,

}

# Choice of optimizer to use

optimizer = optax.adam

# Initialize the optimizer with starting parameters

params_array0, param_lengths = design_to_array(design0)

params_array = np.array(params_array0).copy()

optimizer = optimizer(learning_rate=learning_rate)

opt_state = optimizer.init(params_array)

# Create the minimum feature size array for clipping

minfeatarr = minfeat_cliparray(design=design0)

# Arrays that store the optimization history

objective_history = []

param_history = [params_array]

gradient_history = []

# To use Autograd to calculate the gradient of our objective function, we wrap it within

# Autograd's value_and_grad() function.

obj_fun = partial(objective, param_lengths=param_lengths, wl_range=wl_range)

grad_fn = ag.value_and_grad(obj_fun)

We now run the optimization for 40 iterations with a learning rate of 1e-2, targeting a narrow 10 nm bandwidth from 1545 nm to 1555 nm. Feel free to experiment with the learning rate, step count, or bandwidth range based on your application.

[29]:

for ii in range(num_steps):

print(f"step = {ii + 1}")

# Evaluate the current value and gradient of our objective function with the current parameters.

value, gradient = grad_fn(params_array)

# Print the outputs

print(f"\tJ = {value:.4e}")

print(f"\tgrad_norm = {np.linalg.norm(gradient):.4e}")

# Compute and apply updates to the parameters based on the computed gradient.

# The Optax Adam optimizer is used to compute and apply the updates.

# Note that the gradient is negated for maximizing the objective (the default behavior is to minimize).

updates, opt_state = optimizer.update(-gradient, opt_state, params_array)

params_array = optax.apply_updates(params_array, updates)

params_array = np.array(params_array)

# Enforce DRC constraints by clipping the parameters.

np.clip(params_array, minfeatarr, None, out=params_array)

# Save the results of this iteration step to the history.

objective_history.append(value)

param_history.append(params_array)

gradient_history.append(gradient)

step = 1

J = 2.6875e-01

grad_norm = 2.7844e+00

step = 2

J = 1.7482e-01

grad_norm = 4.3962e+00

step = 3

J = 2.4174e-01

grad_norm = 3.5628e+00

step = 4

J = 2.9479e-01

grad_norm = 1.0747e+00

step = 5

J = 2.4486e-01

grad_norm = 3.4810e+00

step = 6

J = 2.4816e-01

grad_norm = 3.3931e+00

step = 7

J = 2.8747e-01

grad_norm = 1.8932e+00

step = 8

J = 2.9107e-01

grad_norm = 1.6187e+00

step = 9

J = 2.6748e-01

grad_norm = 2.8399e+00

step = 10

J = 2.6989e-01

grad_norm = 2.7722e+00

step = 11

J = 2.9043e-01

grad_norm = 1.6708e+00

step = 12

J = 2.9712e-01

grad_norm = 8.3142e-01

step = 13

J = 2.8138e-01

grad_norm = 2.3528e+00

step = 14

J = 2.7857e-01

grad_norm = 2.5038e+00

step = 15

J = 2.9163e-01

grad_norm = 1.4818e+00

step = 16

J = 2.9914e-01

grad_norm = 4.5491e-01

step = 17

J = 2.9055e-01

grad_norm = 1.5387e+00

step = 18

J = 2.8647e-01

grad_norm = 1.9125e+00

step = 19

J = 2.9191e-01

grad_norm = 1.4884e+00

step = 20

J = 2.9868e-01

grad_norm = 5.3997e-01

step = 21

J = 2.9727e-01

grad_norm = 1.0956e+00

step = 22

J = 2.9105e-01

grad_norm = 1.9127e+00

step = 23

J = 2.9476e-01

grad_norm = 1.5769e+00

step = 24

J = 3.0057e-01

grad_norm = 1.9525e-01

step = 25

J = 2.9814e-01

grad_norm = 1.0031e+00

step = 26

J = 2.9536e-01

grad_norm = 1.4086e+00

step = 27

J = 2.9775e-01

grad_norm = 1.1640e+00

step = 28

J = 3.0147e-01

grad_norm = 1.7777e-01

step = 29

J = 2.9898e-01

grad_norm = 1.0894e+00

step = 30

J = 2.9735e-01

grad_norm = 1.3550e+00

step = 31

J = 3.0087e-01

grad_norm = 7.1540e-01

step = 32

J = 3.0149e-01

grad_norm = 4.7722e-01

step = 33

J = 2.9944e-01

grad_norm = 1.0398e+00

step = 34

J = 3.0016e-01

grad_norm = 9.4444e-01

step = 35

J = 3.0242e-01

grad_norm = 2.5184e-01

step = 36

J = 3.0157e-01

grad_norm = 7.5000e-01

step = 37

J = 3.0061e-01

grad_norm = 1.0277e+00

step = 38

J = 3.0278e-01

grad_norm = 4.6910e-01

step = 39

J = 3.0295e-01

grad_norm = 4.4581e-01

step = 40

J = 3.0200e-01

grad_norm = 8.3474e-01

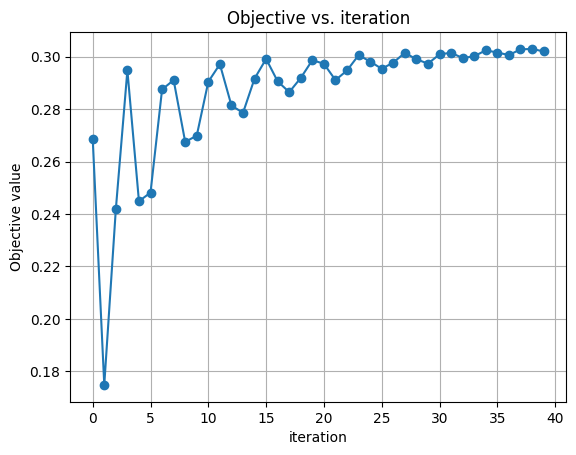

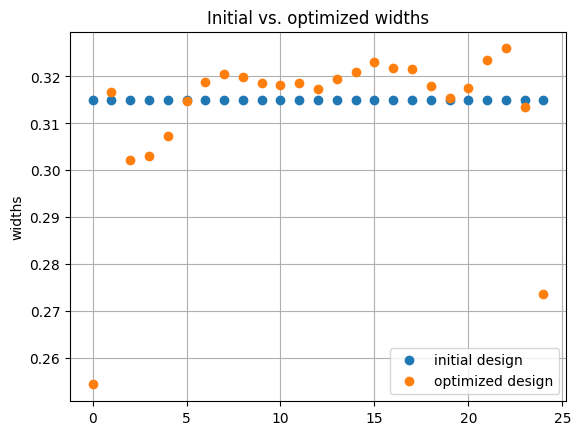

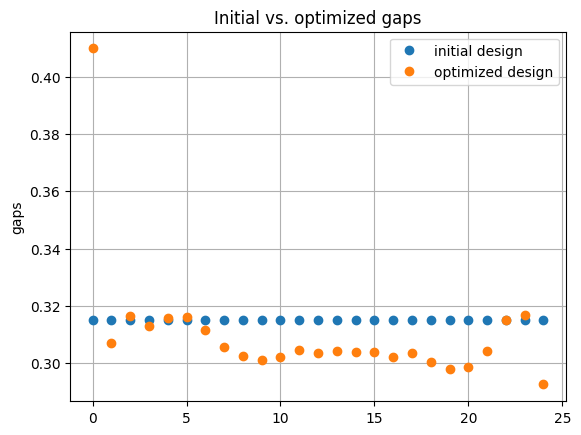

Once the optimization is complete we can view the results:

[30]:

# Plot the objective value versus iteration.

f, ax = plt.subplots()

ax.plot(objective_history, "-o")

ax.set_xlabel("iteration")

ax.set_ylabel("Objective value")

ax.grid()

ax.set_title("Objective vs. iteration")

# Select the best design parameters.

best_params = param_history[np.argmax(objective_history)]

_, param_lengths = design_to_array(design0)

best_design = array_to_design(best_params, param_lengths)

# Compare the starting and final params.

f, ax = plt.subplots()

ax.plot(design0["gc_widths"], "o", label="initial design")

ax.plot(best_design["gc_widths"], "o", label="optimized design")

ax.set_ylabel("widths")

ax.grid()

ax.legend()

ax.set_title("Initial vs. optimized widths")

f, ax = plt.subplots()

ax.plot(design0["gc_gaps"], "o", label="initial design")

ax.plot(best_design["gc_gaps"], "o", label="optimized design")

ax.set_ylabel("gaps")

ax.grid()

ax.legend()

ax.set_title("Initial vs. optimized gaps")

plt.show()

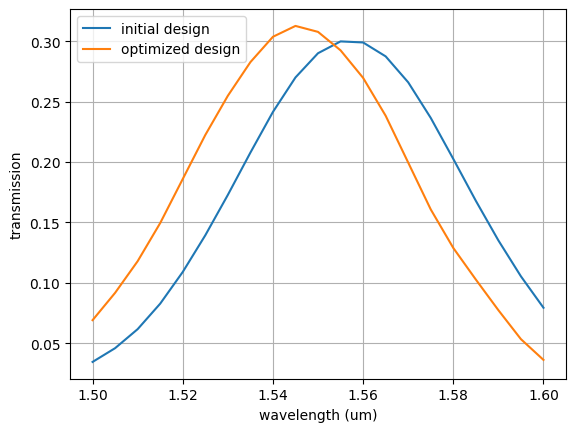

Finally, we can simulate the optimized design, and compare it with the initial design.

[31]:

sim_startdesign = gc_sim(**design0, basesim=basesim)

simdata_startdesign = td.web.run(

sim_startdesign, task_name="gcopt", path="simdata/gcstart.hdf5", verbose=False

)

sim_bestdesign = gc_sim(**best_design, basesim=basesim)

simdata_bestdesign = td.web.run(

sim_bestdesign, task_name="gcopt", path="simdata/gcbest.hdf5", verbose=False

)

[32]:

# Plot final transmission, compare to the initial design

amps_startdesign = simdata_startdesign["P0"].amps.sel(direction="-")

T_startdesign = amps_startdesign.abs**2

amps_bestdesign = simdata_bestdesign["P0"].amps.sel(direction="-")

T_bestdesign = amps_bestdesign.abs**2

f, ax = plt.subplots()

ax.plot(td.C_0 / T_startdesign.f, T_startdesign, label="initial design")

ax.plot(td.C_0 / T_bestdesign.f, T_bestdesign, label="optimized design")

ax.set_xlabel("wavelength (um)")

ax.set_ylabel("transmission")

ax.grid()

ax.legend()

plt.show()

We can see that the final design has centered the transmission spectrum on our design wavelength, and slightly improved the coupling efficiency. More improvement could be possible by experimenting with the optimization hyperparameters, such as the starting design or the coupling bandwidth. Feel free to experiment if you would like and see if you can improve the design even more.